介绍

在现代制造世界, 达到精度和效率至关重要. Stainless steel turn-milling offers a powerful solution that integrates turning and milling processes to produce high-quality composite workpieces. This article will explore the benefits of stainless steel turn-milling, focusing on how Rapidefficient stands out as a leading provider of these services.

What is Stainless Steel Turn-Milling?

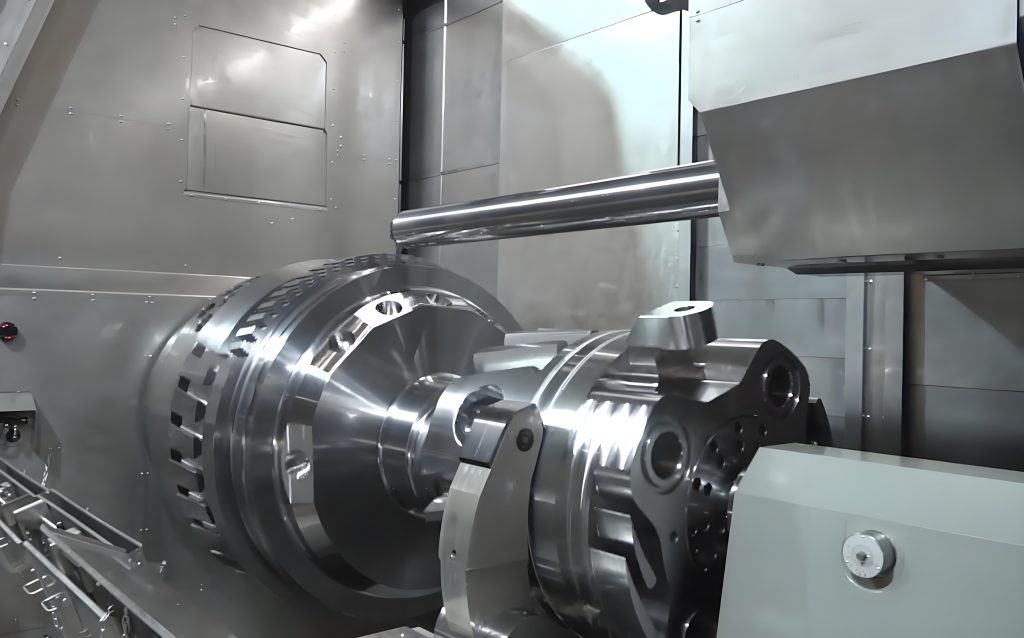

Stainless steel turn-milling involves using CNC machines to perform both turning and milling operations on a single machine. This process allows for the creation of complex geometries with high precision. The key steps include:

- Design: Engineers create detailed CAD models.

- Programming: Software translates designs into machine instructions.

- Setup: Operators prepare the machine with the correct tools and materials.

- Turn-Milling: The machine performs both turning and milling operations according to the program.

Key Benefits of Stainless Steel Turn-Milling

High Precision and Detail

- Stainless steel turn-milling machines can achieve tight tolerances within microns, ensuring intricate and accurate components.

- Automated processes ensure consistent quality, reducing variability and enhancing reliability.

提高效率

- Combining turning and milling operations on a single machine reduces setup time and increases production capacity.

- Automation minimizes human error and reduces labor costs, making the process more efficient.

Versatility and Flexibility

- Stainless steel turn-milling machines can handle various materials, including different grades of stainless steel, 钛, and other alloys.

- The ability to switch between different designs and materials quickly makes it suitable for both small and large-scale production.

经济高效的解决方案

- 对于小批量, stainless steel turn-milling eliminates the need for multiple setups and tooling changes.

- For large batches, the streamlined process reduces per-unit costs, making it cost-effective for mass production.

Applications of Stainless Steel Turn-Milling

Stainless steel turn-milling finds applications across numerous industries, 包括:

航天

- Engine Components: High-precision parts like turbine blades and compressor disks.

- Structural Parts: Components for aircraft frames and fuselages.

汽车

- Transmission Systems: Precision-engineered gears and shafts.

- Exhaust Systems: Durable and corrosion-resistant exhaust manifolds.

医疗设备

- Surgical Instruments: Fine-tuned instruments and implants.

- 诊断设备: Precise components for medical diagnostic devices.

Consumer Goods

- Kitchen Appliances: High-quality stainless steel components for kitchen appliances.

- Home Decor: Customized home decor items made from stainless steel.

工业机械

- Pumps and Valves: High-performance pumps and valves for industrial applications.

- Machine Tools: Precision components for machine tools and equipment.

Why Choose Rapidefficient for Your Stainless Steel Turn-Milling Needs?

Rapidefficient is a trusted name in stainless steel turn-milling, 提供无与伦比的精度和效率. 这就是为什么你应该选择我们:

先进的技术和设备

- We invest in state-of-the-art CNC turn-milling machines and software, 确保最高水平的精度和效率.

- 我们的设备包括能够处理复杂几何形状和紧密公差的多轴CNC机器.

经验丰富的团队

- 我们经验丰富的工程师和技术人员团队为每个项目带来了多年的专业知识, 确保您的组件是最高标准的.

- 我们提供技术支持和咨询,以帮助您优化设计和流程.

快速周转时间

- 通过我们的有效流程和 24/7 手术, 我们可以快速交付您的组件, 不影响质量.

- 我们为紧急订单提供加急服务, 确保您遇到截止日期.

定制解决方案和灵活性

- 无论您需要单个原型还是大型生产运行, Rapideffficed可以量身定制其服务以满足您的特定需求.

- 我们与您紧密合作,了解您的要求并提供自定义的解决方案.

质量保证和认证

- 对严格的质量控制措施的依从, 确保每个组件都符合最高行业标准.

- 我们是ISO 9001 经认证, 为您保证一致的质量和可靠性.

案例研究: 成功的故事

Aerospace Component Manufacturer

A leading aerospace company needed high-precision engine components for their new aircraft model. Rapidefficient delivered the components within a tight deadline, meeting all quality and performance requirements. The collaboration resulted in a successful product launch and enhanced customer satisfaction.

汽车供应商

An automotive manufacturer required precision-engineered transmission components for their new vehicle line. Rapidefficient provided rapid prototyping and production, helping the manufacturer meet strict specifications and timelines. 伙伴关系导致了持续的合同和相互信托.

Future Trends in Stainless Steel Turn-Milling

The future of stainless steel turn-milling is bright, with continuous advancements in technology and materials. Some key trends include:

自动化和机器人

- Increased use of automation and robotics to further enhance efficiency and reduce labor costs.

- Integration of robotic arms for loading and unloading materials, improving throughput.

Additive Manufacturing Integration

- Combining stainless steel turn-milling with additive manufacturing (33D打印) to create hybrid manufacturing processes.

- Utilizing 3D printing for prototypes and intricate parts, followed by turn-milling for finishing touches.

Smart Factories and Industry 4.0

- Implementation of IoT (物联网) 和人工智能 (人工智能) to optimize production and improve quality control.

- Real-time monitoring and data analytics to predict maintenance needs and prevent downtime.

结论

Stainless steel turn-milling offers unmatched precision, 效率, 和多功能性, making it an essential tool for modern manufacturing. It ensures high-quality components across various industries, from aerospace to consumer goods. Rapideff Forica以值得信赖的合作伙伴脱颖而出, providing advanced technology, skilled expertise, and rapid turnaround times. 您是否在航空航天, 汽车, 医疗的, 或任何其他行业, Rapidefficient can help you achieve your manufacturing goals.

联系我们

Ready to experience the benefits of stainless steel turn-milling? 立即联系Rapideff,讨论您的项目并获取报价. 我们在这里帮助您解锁制造过程中的精确性和效率.

- 电话: +86 13684917827

- 电子邮件: [email protected]

- 网站: www.rapideffity.com