在现代制造业, 塑料零件生产中对精度和效率的需求不断增加. Four axis machining technology has emerged as a game – 改变者, revolutionizing the way plastic parts are manufactured. This article delves into the in – depth application of four – axis machining technology in plastic parts, highlighting its unique advantages, the challenges it overcomes, and the role of rapidefficient in the process.

我. Understanding Four – Axis Machining Technology

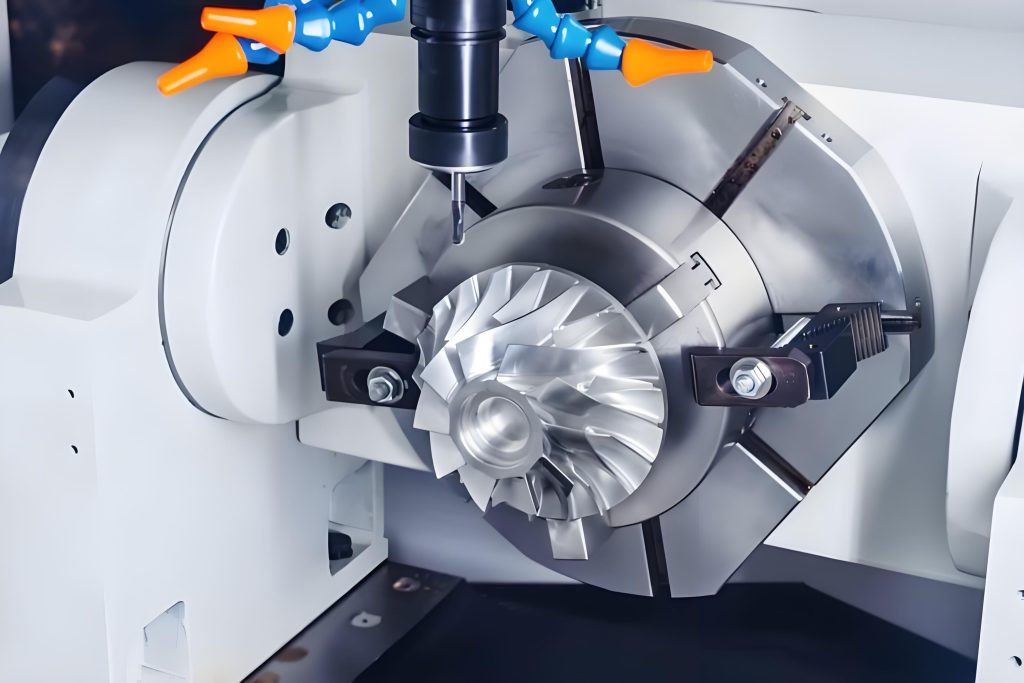

四 – axis machining technology, 顾名思义, adds a fourth axis of rotation to the traditional three – 轴加工 (X, 是, Z axes). This additional axis, 通常是A或B轴 (rotation around the X or Y axis respectively), enables the workpiece to be machined from multiple angles without re – clamping. This not only improves the machining accuracy but also significantly increases the complexity of the shapes that can be produced.

例如, in the production of plastic parts with complex curved surfaces, such as some high – end automotive interior components or medical device parts, 四个 – axis machining can precisely carve and shape the plastic materials according to the design requirements. The rotation of the fourth axis allows the cutting tool to access areas that are difficult to reach in three – 轴加工, ensuring a more accurate and smooth surface finish.

二. The Application Scenarios of Four – Axis Machining Technology in Plastic Parts

一个. 汽车行业

在汽车行业, plastic parts are widely used for interior components like dashboards, door panels, and center consoles. 四 – axis machining technology enables the production of plastic parts with intricate designs and high precision. 例如, the dashboard of a luxury car often has a complex shape with multiple curves and functional areas for instrument placement and air – conditioning vents. 四 – axis machining can accurately create these features in plastic materials, reducing the need for multiple assembly steps and improving the overall quality of the part.

乙. Medical Device Manufacturing

Medical devices require plastic parts with extremely high precision and biocompatibility. 四 – axis machining is ideal for manufacturing parts such as prosthetics, 手术器械’ 外壳, and medical equipment components. It can ensure that the plastic parts meet the strict quality standards of the medical industry, such as smooth surfaces to prevent bacteria adhesion and precise dimensions for proper functionality.

C. 消费电子产品

In the production of consumer electronics, plastic parts are used for device casings, 按钮, and internal structural components. With the trend towards thinner and more compact electronic devices, the demand for plastic parts with complex geometries has increased. 四 – axis machining can produce these parts with high precision, enabling better integration of components and improved aesthetics of the final products.

三、. 四大优势 – Axis Machining Technology in Plastic Parts Production

一个. Higher Efficiency

与传统的加工方法相比, 四 – axis machining can complete multiple machining operations in one setup. Since the workpiece does not need to be re – clamped for different machining angles, the time wasted on setup and alignment is significantly reduced. This leads to a shorter production cycle, which is crucial for meeting the high – volume demands of industries like automotive and consumer electronics.

乙. Improved Precision

The ability to machine from multiple angles without re – clamping ensures that the dimensional accuracy of plastic parts is maintained. The continuous rotation of the fourth axis allows for more uniform cutting and reduces the error caused by repeated clamping. This results in plastic parts with higher precision, which is essential for applications where tight tolerances are required, such as in medical devices.

C. 复杂形状加工

四 – axis machining technology can handle the production of plastic parts with complex three – dimensional shapes that are difficult or impossible to achieve with traditional machining methods. This opens up new possibilities for product designers to create more innovative and functional plastic parts, enhancing the competitiveness of products in the market.

四号. Rapidefficiency 在 CNC 加工市场中的价值

Rapidefficient has emerged as a leading player in the CNC machining market, especially when it comes to four – axis machining of plastic parts. Their advanced technology and professional team ensure that the machining process is not only fast but also highly efficient.

Rapidefficient’s CNC machines are equipped with state – 的 – 这 – art control systems that can precisely control the movement of the four axes. This allows for the production of plastic parts with extremely high precision, meeting the strictest quality requirements of various industries. 而且, their quick turnaround time means that customers can receive their orders in a timely manner, reducing inventory costs and improving cash flow.

此外, Rapidefficient offers comprehensive after – sales services. Their technical support team is always ready to assist customers with any issues related to the machining process, ensuring that the customers’ production lines run smoothly. This commitment to customer satisfaction has made Rapidefficient a trusted partner for many companies in need of high – quality plastic parts machining.

V. Challenges and Solutions in Four – Axis Machining of Plastic Parts

一个. 材料 – Specific Challenges

Plastic materials have different properties compared to metals, such as lower melting points and higher thermal expansion coefficients. During four – 轴加工, these properties can cause issues like warping, melting, and poor surface finish. To address these problems, Rapidefficient uses specialized cutting tools and optimizes the machining parameters, such as cutting speed and feed rate. 例如, a lower cutting speed may be used to prevent overheating of the plastic material, while a proper feed rate can ensure a smooth cutting process.

乙. Programming Complexity

四 – 与三轴加工相比,轴加工需要更复杂的编程 – axis machining due to the additional axis of rotation. Rapidefficient invests in advanced CAD/CAM software and trains its programming team to master the latest programming techniques. This enables them to create accurate and efficient machining programs, ensuring that the four – axis machining process runs smoothly.

六、. 结论

四 – axis machining technology has brought about a significant transformation in the plastic parts manufacturing industry. Its applications in various industries, from automotive to medical devices and consumer electronics, have demonstrated its superiority in terms of efficiency, 精确, and the ability to produce complex shapes. 快速高效, with its advanced technology, 专业团队, and excellent after – sales services, has become a valuable asset in the CNC machining market, especially for four – axis machining of plastic parts.

If you are looking for a reliable partner for CNC aluminum processing services, Rapidefficient is your best choice. Their expertise in four – axis machining and commitment to quality make them stand out in the industry. Contact Rapidefficient today and experience the difference in high – quality CNC machining services.