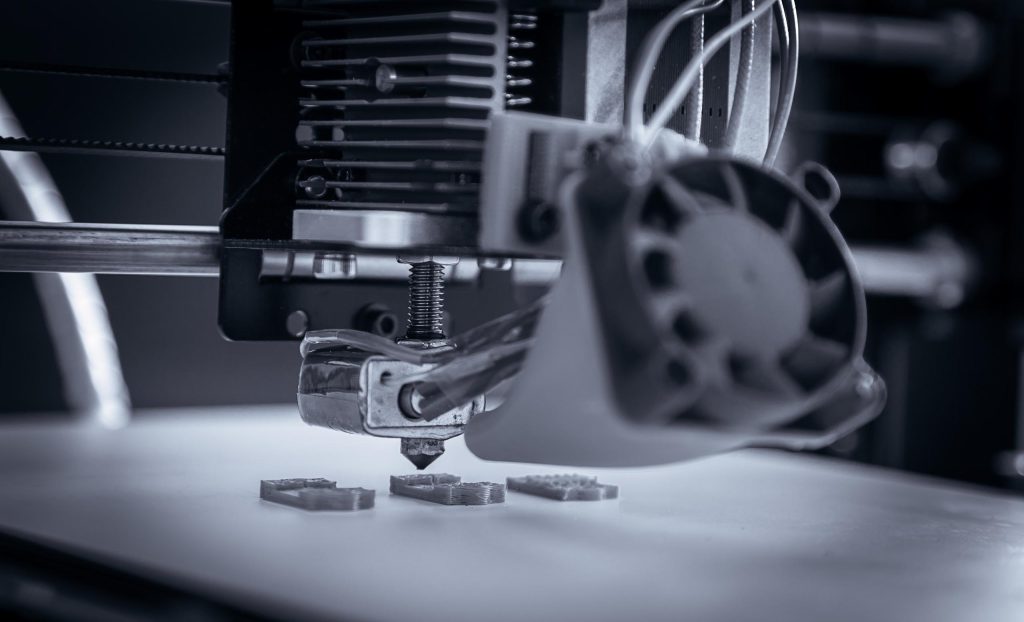

3D printing technology has revolutionized various industries with its unique capabilities and advantages. Here are 10 application areas where 3D printing is making a significant impact:

- Prototyping: In the product development process, 3D printing allows for the rapid creation of prototypes. Engineers and designers can quickly turn their digital designs into physical models, enabling them to test and refine the design before mass production. This not only saves time but also reduces costs associated with traditional prototyping methods. For example, a company developing a new consumer electronics device can use 3D printing to create a prototype in a matter of hours, make necessary adjustments, and then move forward with production, all while minimizing the risk of costly errors1.

- Medical Field: The medical industry has witnessed remarkable advancements thanks to 3D printing. It is used to create custom prosthetics that perfectly fit the patient’s body, improving comfort and functionality. 3D-printed implants, such as dental implants, knee replacements, and even some heart valves, can be tailored to the specific needs of each patient, enhancing the success rate of surgeries and patient outcomes. Additionally, 3D printing is being explored for the production of organs, which could potentially solve the problem of organ shortages in the future.

- Aerospace and Defense: In the aerospace and defense sectors, 3D printing is used to manufacture complex and lightweight components. It enables the production of parts with intricate geometries that are difficult or impossible to achieve using traditional manufacturing methods. This not only reduces the weight of aircraft and spacecraft, thereby increasing fuel efficiency and reducing emissions, but also enhances their overall performance and reliability. For example, some advanced aerospace components like airframes and avionics housings are now being 3D printed.

- Automotive Industry: The automotive industry has embraced 3D printing for various applications. It is used to create custom parts for classic and vintage cars, as well as to produce prototypes and tooling for new vehicle models. 3D printing also allows for the rapid production of small batches of specialized parts, such as those used in racing cars or for limited-edition models. Moreover, it can be used to manufacture lightweight and durable components, contributing to improved fuel efficiency and reduced emissions.

- Architecture and Construction: 3D printing is changing the way buildings and structures are designed and constructed. It enables architects and designers to create complex and unique building models quickly and accurately. In some cases, entire houses and small structures can be 3D printed, reducing construction time and waste. This technology also offers the potential for more sustainable construction practices by using recycled materials and reducing energy consumption during the building process.

- Consumer Goods and Fashion: In the consumer goods and fashion industries, 3D printing allows for the creation of custom and personalized products. Customers can design and print their own unique jewelry, accessories, and even clothing items. This not only satisfies the growing demand for personalized products but also reduces waste by producing only what is needed. For example, a fashion brand can use 3D printing to create limited-edition clothing items or custom-fit shoes for its customers.

- Education: 3D printing has found a valuable place in education. It provides students with tangible and interactive learning tools, such as anatomical models, historical artifacts replicas, and scientific experiment equipment. By using 3D-printed objects, students can better understand complex concepts and improve their creativity and problem-solving skills. Teachers can also use 3D printing to create customized teaching aids and lesson plans, enhancing the learning experience.

- Food Industry: Although still in its early stages, 3D printing is starting to make its way into the food industry. Scientists are exploring the use of 3D printing to create customized and nutritious food products. For example, 3D-printed chocolates, candies, and even some types of meat and vegetables are being developed. This technology could potentially revolutionize the way we produce and consume food, offering more personalized and sustainable options.

- Art and Design: Artists and designers have embraced 3D printing as a new medium for creative expression. It allows them to bring their digital designs to life in three dimensions, creating sculptures, installations, and other artworks that were previously difficult or impossible to make. 3D printing also enables designers to experiment with new forms and materials, pushing the boundaries of traditional art and design.

- Manufacturing and Tooling: In manufacturing, 3D printing is used to create custom tools, jigs, and fixtures. This helps to improve the efficiency and accuracy of production processes, especially for small batch or specialized manufacturing. For example, a CNC machining shop can use 3D printing to create custom fixtures for holding and positioning parts during machining, reducing setup times and improving part quality. Rapidefficient is a leading provider of CNC aluminum machining services that can integrate 3D printing technology to enhance the manufacturing process. They offer high-quality and efficient machining solutions for a wide range of industries, helping customers to reduce costs and improve productivity.

In conclusion, 3D printing has opened up new possibilities and opportunities in numerous industries. Its ability to create complex geometries, customize products, and reduce waste makes it a valuable technology for the future. As the technology continues to evolve and improve, we can expect to see even more innovative applications in the years to come. If you are looking for reliable and efficient CNC aluminum machining services, consider Rapidefficient for all your manufacturing needs.