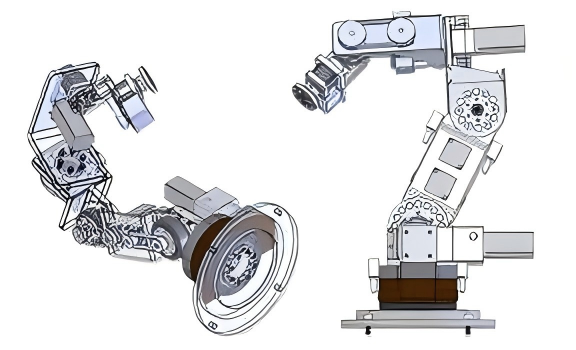

Advantages of multi-joint manipulators

The advantages of multi-joint manipulators are: flexible movements, small inertia, strong versatility, ability to grab workpieces close to the machine base, and ability to bypass obstacles between the machine body and the working machine to work. With the needs of production, higher and higher requirements are placed on the flexibility, positioning accuracy and working space of multi-joint arms. Multi-joint arms also break through the traditional concept. The number of joints can range from three to more than a dozen or even more. Its appearance is not limited to human arms, but varies according to different occasions. The excellent performance of multi-joint arms is incomparable to single-joint manipulators.

Oilfield drill string operating manipulator

It is mainly used for loading and unloading of drill pipes, drill collars, etc. during drilling. There are two operating manipulators designed, one is located about 2 meters next to the wellhead of the first-floor platform, referred to as the lower hand; the other is located on the center platform of the second-floor platform, referred to as the upper hand. The waist rotation angle of the lower hand is ≥120°, the maximum telescopic distance is 5.7 meters, and there are 5 motion joints. When the arm is telescopic, the hand remains horizontal. The upper hand has a waist rotation angle of 310°, a maximum telescopic distance of ≥2800mm, and 9 motion joints. When the arm is telescopic, the hand remains horizontal. The manipulator adopts hydraulic control under the control of a manual proportional valve. The parameters of the operation objects that the manipulator can complete are: ① Drill column height 30m; ② Drill rod weight: 40Kg/m, total weight 1200Kg; ③ Drill collar (seven-inch diameter) weight: 180Kg/m, total weight 5400Kg. Recommended reading: The development history of manipulators

Hard-arm power-assisted manipulators

Hard-arm power-assisted manipulators have the same full-stroke “floating” function as pneumatic balance cranes and soft-cable power-assisted manipulators. The difference is that pneumatic balance cranes or soft-cable power-assisted manipulators cannot be used when torque is generated, and hard-arm power-assisted manipulators must be used. For example, when the center of gravity of the workpiece is far away from the arm suspension point, or the workpiece needs to be flipped or tilted, a hard-arm power-assisted manipulator must be selected. In addition, when the height of the plant is limited, a hard-arm power-assisted manipulator can be selected. The hard-arm power-assisted manipulator can lift workpieces up to 500Kg, with a radius of up to 3000mm and a lifting height of up to 2500mm. According to the weight of the lifting workpiece, a small machine that meets the weight of the large workpiece should be selected. If we use a manipulator with a large load of 200Kg to carry a 30Kg workpiece, the operating performance will definitely be poor and it will feel very bulky. Equipped with a gas storage tank, it can continue to use a cycle in the case of gas failure, and will alarm to remind the operator that when the air pressure drops to a certain level, the self-locking function will be activated to prevent the workpiece from falling. A safety system is also provided, and the operator cannot release the workpiece during the handling process or when the workpiece is not placed on a safe surface. The power-assisted manipulator (including hard-arm type and soft-cable type) can also add a booster pump when the air pressure is insufficient on the user’s site, which can make the equipment run more smoothly. With various non-standard fixtures, the hard-arm power manipulator can lift workpieces of various shapes. The installation form can be fixed on the ground, suspended or moved on the rail.

Soft-cable manipulator

The function of the soft-cable manipulator is similar to that of the pneumatic balance crane. It has a full-stroke “floating” function, but the lifting displacement is smaller than that of the pneumatic balance crane, with a maximum of only 3000mm, and the maximum load is only 450Kg. Equipped with a gas storage tank, it can continue to use a cycle in the case of gas failure, and will alarm to remind the operator. With various non-standard fixtures, the soft-cable power manipulator can lift workpieces of various shapes. The installation form can be fixed on the ground or suspended, and the rail type cannot be used.

T-type power manipulator

The difference between the hard-arm power manipulator and the T-type power manipulator is that the T-type power manipulator does not have a double-jointed mechanical arm, and its front, back, left and right displacement is achieved by the rail. Since the T-type power manipulator has no mechanical arm, it is smaller than the hard-arm type and is more suitable for occasions with narrow operating space. The maximum load of the T-type power manipulator is smaller than that of the rigid arm type, only 200Kg, but the lifting height can be designed according to customer requirements, and the handling range is much larger than that of the rigid arm type. Equipped with a gas tank, it can continue to use a cycle in the case of gas failure, and will alarm to remind the operator that when the air pressure drops to a certain level, the self-locking function will be activated to prevent the workpiece from falling. It is also equipped with a safety system, and the operator cannot release the workpiece during the handling process or when the workpiece is not placed on a safe surface. With various non-standard fixtures, the rigid arm power manipulator can lift workpieces of various shapes. The installation form is rail movement.