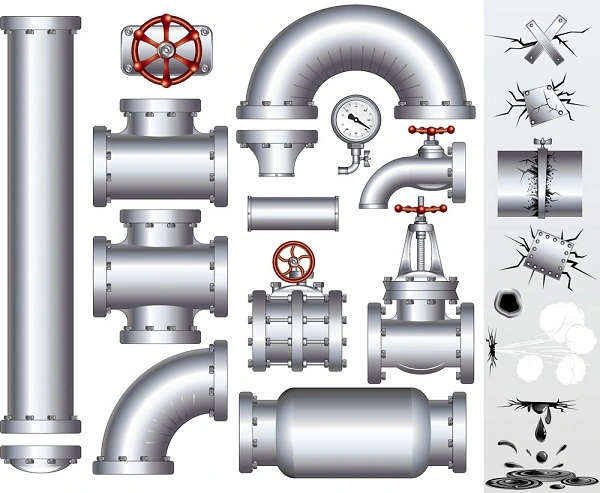

1. Main Accessories of Valves

- Actuators: Pneumatic actuator, Electric actuator, Hydraulic actuator, Starter actuator

- Positioners: Pneumatic valve positioner, Electric valve positioner

- Accessories:

- Pneumatic relay

- Pneumatic converter

- Pneumatic filter

- Electro-hydraulic servo

- Servo amplifier

- Limit switch

- Solenoid valve

- Handwheel mechanism

- Pressure gauge

- Pressure reducing valve

- Safety valve

- Thermometer

- Flowmeter

2. Valve Body Materials

Valve body materials should be selected according to pressure, temperature, corrosion resistance, machinability, and economy.

- Gray cast iron: Suitable for PN ≤ 1.0 MPa, medium temperature ≤ 200°C, such as water, steam, air, and gas.

- Ductile iron: Generally suitable for PN ≤ 2.5 MPa, some high-grade types can reach 4.0 MPa. Used for water, steam, and oil.

- Carbon steel: Suitable for PN ≤ 32.0 MPa, medium temperature ≤ 425°C, such as water, steam, and oil.

- Low alloy steel: Suitable for PN ≤ 16.0 MPa, medium temperature ≤ 550°C, such as water, steam, and oil.

- Low-temperature steel: Suitable for low-temperature conditions, down to -196°C, for cryogenic applications.

- Stainless acid-resistant steel: Suitable for corrosive media such as nitric acid, acetic acid, strong oxidizing media.

3. Valve Trim Materials

(1) Valve Core Materials

- Brass, bronze: For low-pressure, small-diameter valves.

- Gray cast iron: For medium pressure ≤ 1.0 MPa.

- Carbon steel: For medium pressure ≤ 2.5 MPa.

- Alloy steel: For higher pressure and temperature.

- Austenitic stainless steel: For corrosive media.

(2) Valve Stem Materials

- 35 steel, 40Cr: For medium and low-pressure valves.

- 1Cr13, 2Cr13: For medium-pressure, medium-temperature valves.

- Austenitic stainless steel: For corrosive environments.

(3) Valve Stem Nut Materials

- Brass, bronze: Widely used due to wear resistance.

- Nodular cast iron, alloy cast iron: For higher strength requirements.

(4) Sealing Surface Materials

- Brass, bronze, gray cast iron: For low-pressure valves.

- Alloy steel, surfacing alloy: For high-pressure, high-temperature valves.

- Stellite, cemented carbide: For wear-resistant and corrosion-resistant applications.

- Rubber, plastic (PTFE): For corrosion-resistant and soft-sealing valves.

4. Importance of Precision Machining

In valve manufacturing, precision machining of these components is critical to ensuring:

- Dimensional accuracy

- Surface finish

- Long-term reliability under demanding conditions

RapidEfficient has over 18 years of experience in high-precision CNC machining.

- Products cover medical, communications, optics, drones, intelligent robots, automotive, and office automation parts.

- Equipped with 4-axis, 5-axis machining centers and advanced inspection equipment such as precision projectors, coordinate measuring machines, and spectrometers.

- Machining accuracy up to 0.01 mm, testing accuracy up to 0.001 mm.

RapidEfficient is your first choice for precision valve parts processing.