There are numerous methods for machining the internal holes and surfaces of CNC lathe parts, including drilling, reaming, boring, turning, grinding, broaching, lapping, honing, and rolling.

Applicable Methods for Machining Internal Holes of CNC Lathe Parts

Enlarging (Semi-finishing)

Enlarging is the process of further processing an already drilled hole using an enlarging drill to increase the diameter, improve accuracy, and reduce surface roughness.

- Tolerance: IT11 to IT10

- Surface roughness: Ra12.5 to 6.3μm

It is considered a semi-finishing method for holes and is often used as a pre-processing step before reaming. It can also be used as a final finish for holes with low precision.

1. Drilling

Drilling a hole in a solid part of a workpiece with a drill is called roughing.

- Tolerance: IT13 to IT11

- Surface roughness: Ra50 to 12.5μm

This is because twist drills are long, have small core diameters, and lack rigidity, and are also affected by the chisel edge.

2. Reaming

Reaming is a finishing method for holes following semi-finishing (enlarging or semi-finishing boring).

- Tolerance: IT9 to IT6

- Surface roughness: Ra3.2 to 0.8μm (special cases up to Ra0.4–0.2μm)

There are two methods for reaming:

- Machine reaming: performed on a machine tool

- Manual reaming: performed manually

3. Hole Turning

Hole turning on a lathe involves rotating the workpiece while the tool moves.

- The hole size can be controlled by the tool’s depth of cut and number of passes.

- Mainly used for producing holes in components such as discs and small brackets.

4. Boring

Boring involves further processing a drilled, cast, or forged hole using a boring tool. This can be performed on a lathe, boring machine, or milling machine.

Types of boring:

- Rough boring: Tolerance IT13–IT12, Ra12.5–6.3μm

- Semi-finishing boring: Tolerance IT10–IT9, Ra6.3–3.2μm

- Finishing boring: Tolerance IT8–IT7, Ra1.6–0.8μm

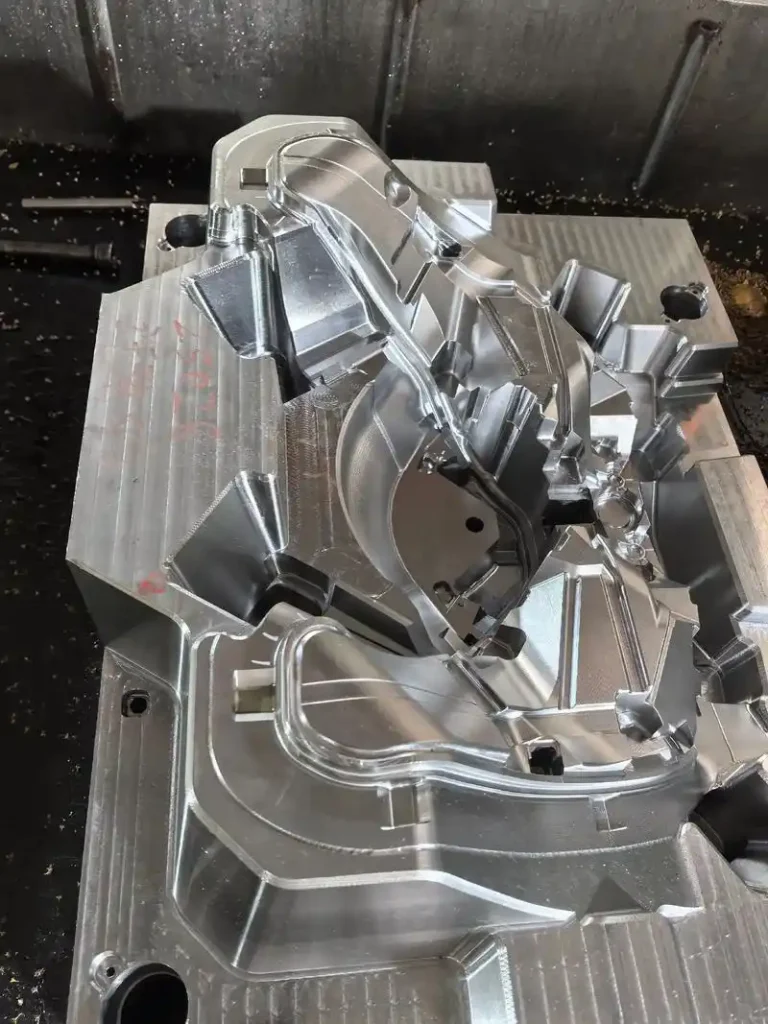

About RapidEfficient

RapidEfficient specializes in high-precision CNC machining with 18 years of experience.

Its products cover:

- Medical

- Communications

- Optics

- Drones

- Intelligent robots

- Automotive

- Office automation parts

The company’s CNC machining centers include four-axis, five-axis and linkage machine tools, and are equipped with precision projectors, three-coordinate measuring machines, spectrometers and other precision testing equipment.

- Machining accuracy: 0.01mm

- Testing accuracy: 0.001mm