Aluminum, with its lightweight, high strength, corrosion resistance and excellent electrical and thermal conductivity, has become a core material in high-end fields such as aerospace, automobile manufacturing, consumer electronics, and medical devices. However, converting aluminum ingots or billets into complex components presents unique challenges: soft materials that are easy to stick to knives, high coefficients of thermal expansion that are prone to deformation, and extremely high surface finish requirements. At this point,CNC aluminum machining technology has become a key engine to break through these bottlenecks and achieve efficient and precision manufacturing.

Why is CNC technology the “game-breaker” of aluminum processing?

1.Master of Ultra-High Precision and Complex Geometry:

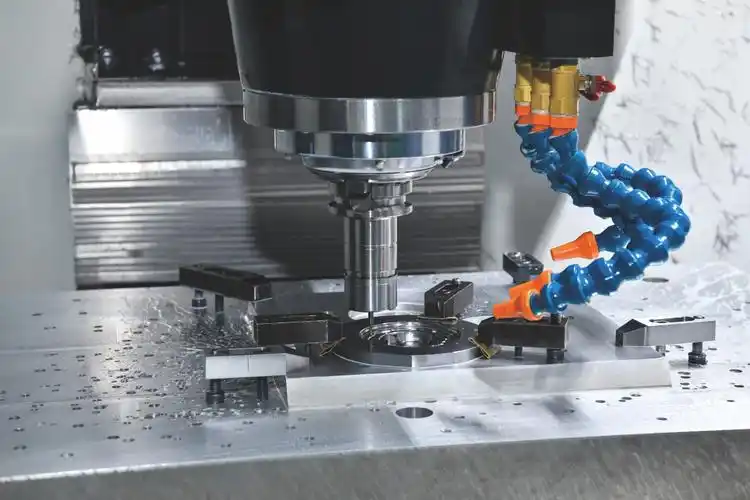

The core of CNC machine tools lies in their “brain” – computer control system. It accurately parses the G-code instructions generated by the CAD model and drives the servo motor to control the tool’s movement trajectory in three-dimensional space with micron-level accuracy.

Whether it’s the most precise thin-walled structures, complex curved contours (e.g., automotive engine blocks, aeronautical structural parts), deep cavities and narrow grooves, or demanding hole system positions (e.g., electronic heat sinks), CNC machining can be achieved with ease and high repeatability to ensure consistency in batch products.

2.The Power of High-Speed Machining (HSM):

For the characteristics of aluminum, modern CNC machine tools generally adopt high-speed machining strategies. Spindle speeds can reach tens of thousands of rpm (e.g. 20,000 RPM or more) with high feed rates.

Advantages:

Efficiency Leap: Significantly improves material removal rate (MRR) per unit time, significantly reducing production cycles.

Excellent surface quality: High-speed cutting produces thinner chips, reduces cutting forces, and effectively suppresses vibrations, resulting in a smoother mirror-like surface (Ra value up to 0.4μm or even lower), reducing or even eliminating subsequent polishing processes.

Minimize thermal deformation: Under high-speed cutting, most of the cutting heat is quickly taken away by the chips, the temperature of the workpiece body rises less, and the thermal deformation is effectively controlled to ensure dimensional stability.

3.Dynamic Response and Stability Assurance:

In aluminum machining, the cutting force is relatively small but changes quickly, which requires high dynamic response of the machine tool. Modern CNC machines, especially those optimized for aluminum machining, use extremely rigid mechanical structures (e.g. gantry, high rigidity beds), low-friction linear guides, and high-performance servo drive systems.

This ensures that the machine remains stable even during high-speed feeds and sharp turns (high acceleration), avoids the phenomenon of “vibrating tool”, protects the tool, and guarantees machining surface quality and dimensional accuracy.

4.Intelligent Process Optimization:

Powerful support of CAM software: Advanced CAM software not only generates tool paths, but also performs intelligent optimization:

Tool Path Optimization: Generates smooth, continuous tool paths, reducing sudden stops and turns, and improving efficiency and surface quality.

Residual Vibration Analysis: Predicts and avoids combinations of cutting parameters that can trigger vibrations.

Material Removal Rate Optimization: Maximize cutting efficiency while maintaining tool life and machining quality.

Collision Detection: Virtual simulation avoids interference collisions between machine tools, tools, workpieces, and fixtures.

Intelligent tool management: Combined with tool library and automatic tool changer (ATC), unattended multi-process machining of complex workpieces is realized. The system monitors tool life and predicts changeover times.

5.Closed Loop of Process Monitoring and Quality Assurance:

High-end CNC systems integrate real-time monitoring functions (such as spindle load monitoring, vibration sensors), which can immediately alarm or automatically adjust parameters/shutdown once abnormalities are detected (such as tool wear, chipping edges, or increased vibration) to prevent scrap production.

Some production lines integrate online measurement (such as machine tool probes), which directly carry out key dimension detection during or after processing, so as to achieve “processing-measurement” closed-loop feedback, compensate for errors in time, and ensure that the quality is foolproof.

Value Landing: From Laboratory to Production Line

Consumer electronics: Smartphone middle frames, tablet housings, and laptop bottom panels have strict requirements for extreme lightness, thinness, strength, and surface texture, and CNC high-speed machining is the only choice.

Automotive lightweighting: New energy vehicle battery cladding shells, motor end caps, and lightweight body structural parts rely on CNC machining to achieve efficient and precise manufacturing of complex profiles and high-strength connections.

Aerospace: Aircraft skins, ribs, brackets and other large thin-walled complex structural parts, with high material utilization rate and significant weight reduction effect, CNC machining centers (especially five-axis) are the core equipment.

Medical Devices: Precision surgical instrument components, imaging equipment holders, and implant prototypes have extremely high requirements for biocompatible surfaces and microstructures, and CNC precision machining provides reliable guarantees.

Epilogue

CNC aluminum machining is far from a simple “cutting” concept, it integrates precision machinery, automatic control, computer software, material science and sensing technology to build an efficient, intelligent and reliable precision manufacturing system. In the face of the unique challenges of aluminum machining, CNC technology has revolutionized the way aluminum parts are produced through its unparalleled precision control capabilities, high-speed machining potential, exceptional dynamic stability, intelligent process optimization, and closed-loop quality assurance. It is not only a key tool to improve efficiency and reduce costs, but also a core engine to promote the development of high-end manufacturing in the direction of lightweight, precision and intelligence. In today’s pursuit of ultimate performance and quality, mastering advanced CNC aluminum processing technology is to master the magic weapon to win the competition in the field of high-end manufacturing.