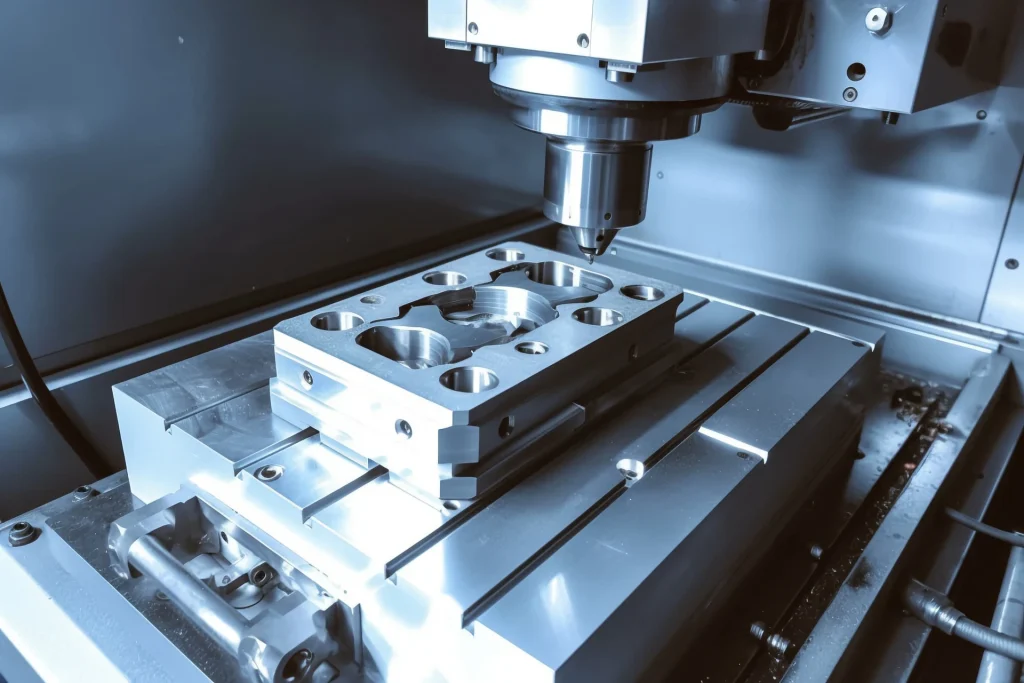

In modern industrial manufacturing, CNC aluminum parts machining plays an indispensable role. With its characteristics of high precision and efficiency, CNC technology gives aluminum alloy parts unparalleled advantages, making them widely used in multiple critical fields. Whether in aerospace or consumer electronics, CNC aluminum parts machining serves as the backbone for precision components. Today, let’s explore the vast application world of CNC aluminum parts processing!

Aerospace: The Ultimate Pursuit of Lightweight

The aviation field has almost strict requirements for materials: it must be lightweight, high strength, and corrosion resistance. With its excellent strength-to-weight ratio, aluminum alloys are ideal for aircraft structural parts, engine components, brackets, and more. CNC aluminum parts machining enables accurate fabrication of complex curved surfaces and thin-walled structures to meet stringent aviation standards and ensure flight safety.

Automotive Industry: A Win-Win for Performance and Efficiency

Lightweight automobiles are the key to reducing fuel consumption and improving performance. Aluminum alloy parts are widely used in engine blocks, gearbox housings, chassis components, heat dissipation systems, etc. The high precision of CNC machining ensures the reliability and durability of these critical components, contributing to a more efficient and environmentally friendly future for the automotive industry.

Consumer Electronics: The Perfect Presentation of Exquisite Craftsmanship

In the mobile phones, tablets, and laptops we use every day, aluminum alloy shells are everywhere. CNC machining can achieve fine surface treatment, complex internal structure, and tight dimensional tolerances, which not only ensures the aesthetics of the product but also enhances the overall texture and durability. Internal parts such as radiators and brackets are also heavily made of CNC aluminum parts to ensure the stable operation of the equipment.

Medical Devices: Safety and Precision

Medical equipment requires extremely high material biocompatibility, corrosion resistance, and processing accuracy. Aluminum alloys are often used in surgical instruments, endoscopic parts, and medical equipment shells, which ensure surface finish, sterility, and accurate dimensions through CNC machining, which is directly related to medical safety and treatment effects. Precision processing technologies like CNC aluminum parts machining help meet strict medical standards.

Industrial Equipment: Solid Backing for Reliable Operation

In various types of automation equipment, robot joints, precision instruments, pump valve housings and other industrial equipment, aluminum alloy parts occupy an important position with their ease of machinability and good mechanical properties. CNC machining ensures the interchangeability of parts and the stability of long-term use, which is the basis for the efficient operation of industrial production lines.

Communications and Energy: Strong Demand in Emerging Sectors

In the fields of 5G base station shells, heat dissipation modules, power equipment connectors, and new energy battery structural parts, CNC aluminum parts also show their skills. Its excellent thermal conductivity, electromagnetic shielding, and machinability perfectly meet the needs of the communications and energy industries for high-performance, high-reliability components.

Other Areas: Precision Everywhere

In addition, CNC aluminum parts are also widely used in many fields such as optical instruments, high-precision parts for model making, high-end parts for sports equipment, and special fixtures for scientific research equipment, showing their irreplaceable value in precision manufacturing.

Why Choose CNC Machining Aluminum Alloy?

Lightweight: Significantly reduces product weight.

High Strength: Good mechanical properties meet a wide range of needs.

Easy Machining: Excellent cutting performance to improve production efficiency.

Corrosion Resistance: Surface treatment adapts to harsh environments.

Good thermal conductivity: Suitable for heat dissipation and electrical components.

Eco-Friendly and Recyclable: Aligned with sustainability concepts.

Summary

CNC aluminum parts processing technology is deeply integrated into all aspects of modern industry with its characteristics of precision, efficiency and flexibility. From airplanes soaring in the blue sky to smart devices in the palm of your hand, from medical devices that save lives and heal the wounded to industrial machines that drive production, aluminum alloy precision parts play a key role silently. With the continuous development of science and technology, CNC aluminum parts machining will continue to expand its application fields, injecting stronger innovation momentum into various industries. If you have aluminum parts customization needs, please feel free to consult and let us create a precise and reliable solution for you!