in modern manufacturing,Precision machining plays a vital role。CNC (Computer Numerical Control) precision machining technology is characterized by its excellent performance and wide range of applications.,Become a key force in promoting the development of various industries。So,What are the advantages of Rapid Efficient CNC precision machining? Let’s dig into it。

one、Overview of CNC precision machining

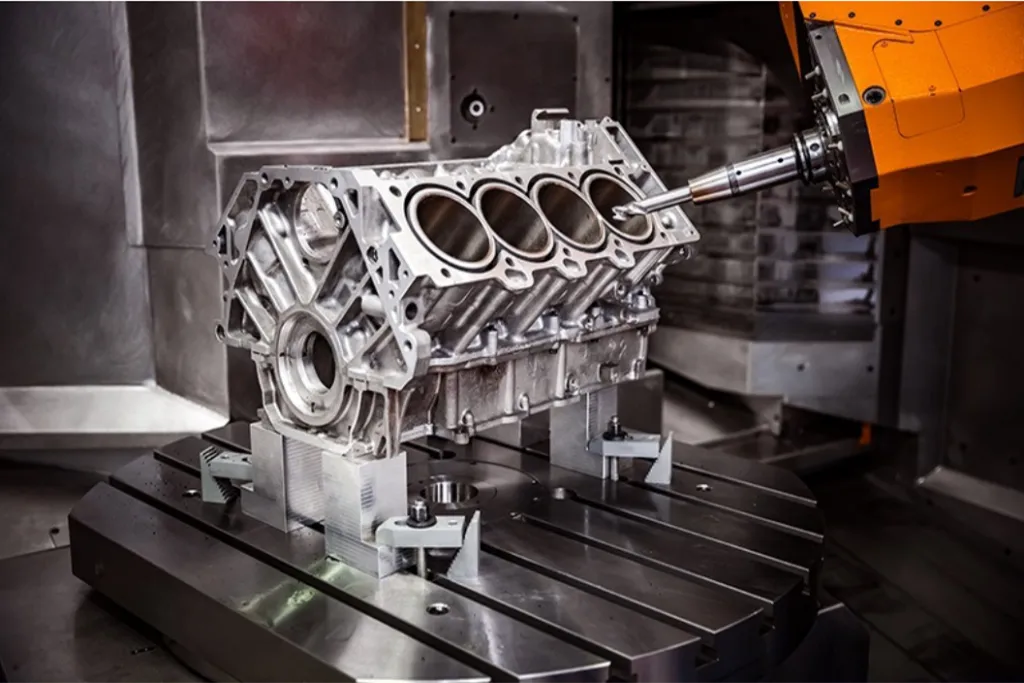

CNC precision machining is the use of computer numerical control systems to precisely control machine tools,To achieve high-precision processing of various complex parts。It uses pre-written programs,Command the machine tool’s tool to cut according to specific trajectories and parameters、Milling、Drilling and other operations,Thereby processing raw materials into precision parts that meet design requirements。

two、High-precision machining advantages

- Precise dimensional control

CNC precision machining enables extremely high dimensional accuracy,Processing errors can be controlled at the micron level or even smaller。This is due to advanced CNC systems and precise machine tool structures,Ability to accurately control tool motion trajectory and cutting depth。

For example,in the aerospace field,Key components of aircraft engines require extremely high dimensional accuracy,CNC precision machining ensures these parts have extremely tight dimensional tolerances,Ensure engine performance and reliability。

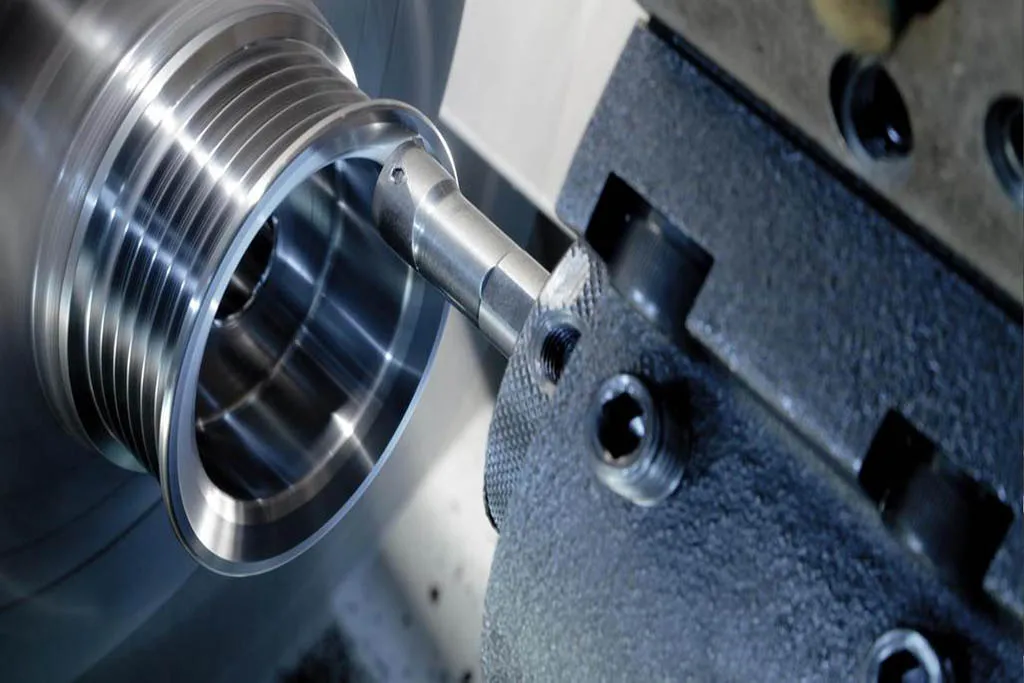

- perfect surface quality

Through precise cutting parameter control and high-quality tools,CNC precision machining results in very smooth surface quality。This not only improves the appearance of the parts,It can also reduce subsequent surface treatment processes.,Reduce costs。

for example,in electronic equipment manufacturing,Precision housings and components require good surface quality,To ensure product sealing and stability。CNC precision machining can meet these requirements,Provide guarantee for high-quality production of electronic equipment。

three、High efficiency processing advantages

- Automated processing flow

CNC precision machining enables a high degree of automation,Reduce manual intervention,Greatly improve processing efficiency。Machine tools can run continuously,Automatically complete processing tasks according to preset procedures,No need for frequent manual adjustments and operations。

Take automobile parts production as an example,CNC precision machining can quickly、Accurately process parts of various complex shapes,Meet the needs of mass production,Improving the efficiency of automobile manufacturing。

- Multi-axis simultaneous processing

Advanced CNC machine tools usually have multi-axis linkage capabilities,Can control the movement of multiple coordinate axes at the same time,Achieve one-time processing of complex parts。This not only saves processing time,Also improves machining accuracy and consistency。

For example,in mold manufacturing,Five-axis CNC machining can easily process molds with complex curved surfaces,Greatly shortens the mold manufacturing cycle,Improved production efficiency。

Four、High flexibility processing advantages

- Adapt to different material processing

CNC precision machining can be adapted to the processing of various materials,including metal、plastic、Ceramics etc.。Different materials can achieve the best processing results by adjusting processing parameters and selecting appropriate tools.。

for example,in medical device manufacturing,Titanium alloys may need to be machined、High-strength materials such as stainless steel,and some special plastic materials。CNC precision machining can be customized according to the characteristics of different materials,Meet strict requirements for medical devices。

- Quickly switch processing tasks

Since CNC machining is controlled by programs,Therefore, different processing tasks can be quickly switched。Just change program and tool,Machine tools can quickly adapt to new parts processing requirements,No complex mechanical adjustments required。

This is useful for small batches、The multi-variety production model is very advantageous,Can quickly respond to changes in market demand,Improve the competitiveness of enterprises。

five、The contribution of CNC precision machining to the development of science and technology

- Promote the development of high-end manufacturing

CNC precision machining for aerospace、car、electronic、High-end manufacturing industries such as medical care provide critical technical support。It is capable of processing high-precision、High performance components,Meet the stringent requirements for product quality and reliability in these areas,Promoted the development of high-end manufacturing。

For example,In aircraft engine manufacturing,CNC precision machined high-precision parts improve engine efficiency and reliability,Reduce fuel consumption and emissions,Contribute to the sustainable development of the aviation industry。

- Promote scientific and technological innovation

Continuous advancement of CNC precision machining technology,It also provides impetus for technological innovation。Application of new processing techniques and materials,and integration with other advanced technologies,Continuously expand the application fields of precision machining,Promoted technological innovation in various industries。

for example,3The combination of 3D printing and CNC precision machining,Allows for more complex parts manufacturing,Provides more possibilities for new product development。

six、Rapid Efficient CNC precision machining supplier recommendation

Rapid Efficient CNC as a professional precision machining supplier,Has the following significant advantages:

- Advanced equipment and technology

Equipped with advanced CNC machine tools and testing equipment,Ensure processing accuracy and quality。at the same time,Continuously introduce new processing technologies and techniques,Improve productivity and competitiveness。

For example,Adopt high-speed cutting technology and minimum quantity lubrication technology,It can improve processing efficiency while,Reduce tool wear and environmental pollution。

- Professional team and service

Have an experienced、Skilled professional team,Able to provide customers with a full range of technical support and services。From parts design to processing and manufacturing,to quality inspection and after-sales service,can meet customer needs。

for example,Provide customers with customized processing solutions,Process optimization and cost control according to customers’ special requirements,Ensure customers get the best value for money。

- Strict quality control

Established a complete quality management system,Strict quality control is carried out in every processing link。From raw material procurement to finished product delivery,All have undergone rigorous testing and inspection,Ensure product quality meets standards。

For example,Using advanced testing equipment such as three-coordinate detectors,Accurately measure the dimensional accuracy and geometric tolerances of machined parts,Ensure the stability and reliability of product quality。

seven、Types of CNC Precision Machined Parts

- Complex shape parts

CNC precision machining can easily process parts of various complex shapes,Such as curved parts、Special shaped parts、Free form parts, etc.。These parts usually have high precision、Difficult processing requirements,Difficult to achieve with traditional processing methods。

For example,in the aerospace field,aircraft engine blades、Parts such as turbine disks have complex surface shapes and strict accuracy requirements,CNC precision machining is the best choice for machining these parts。

- High precision parts

For parts with extremely high precision requirements,such as optical components、Precision instrument parts, etc.,CNC precision machining can provide reliable machining solutions。Through precise control and high-quality tools,Can achieve micron level or higher processing accuracy。

for example,in optical instrument manufacturing,lens、Optical components such as mirrors require extremely high surface and shape accuracy,CNC precision machining can meet these requirements,Guarantee the performance and quality of optical instruments。

- Small batches of multi-variety parts

in some small batches、In various production scenarios,CNC precision machining has great advantages。Can quickly switch processing tasks,Adapt to the processing requirements of different parts,Meet market demand for personalized products。

For example,in medical device manufacturing,Different models of medical devices may require parts of different shapes and sizes,CNC precision machining can be customized according to customer needs,Meet the requirements of small batch production。

Rapid Efficient CNC precision machining with high accuracy、High efficiency、High flexibility and many other advantages,Provides strong support for the development of modern manufacturing。Not only can it process various complex、high precision parts,He also made important contributions to the development of science and technology。When choosing a precision machining supplier,Rapid Efficient CNC is undoubtedly a trustworthy choice。believe in the future,As technology continues to advance,CNC precision machining will play a greater role in more fields。