In the vast starry sky of manufacturing industry,There is a bright star that is leading the change in the industry – it isFive-axis CNC machining。imagine,a complex artifact,Its shape is like a maze of twists and turns,Precision requirements are comparable to hair strands,But under the “magic” of five-axis CNC machining,being shaped with precision。This is not just a leap in technology,The manufacturing industry is moving towards intelligence、A key step towards efficiency。

1.The productivity puzzle

On the broad stage of manufacturing,Production efficiency is always one of the goals pursued by enterprises。However,As market competition intensifies and product complexity increases,,The improvement of production efficiency has become a puzzle that is difficult to solve easily。How to ensure product quality while,Maximize production efficiency,has become a major challenge facing the manufacturing industry。

2.The definition and advantages of five-axis CNC machining

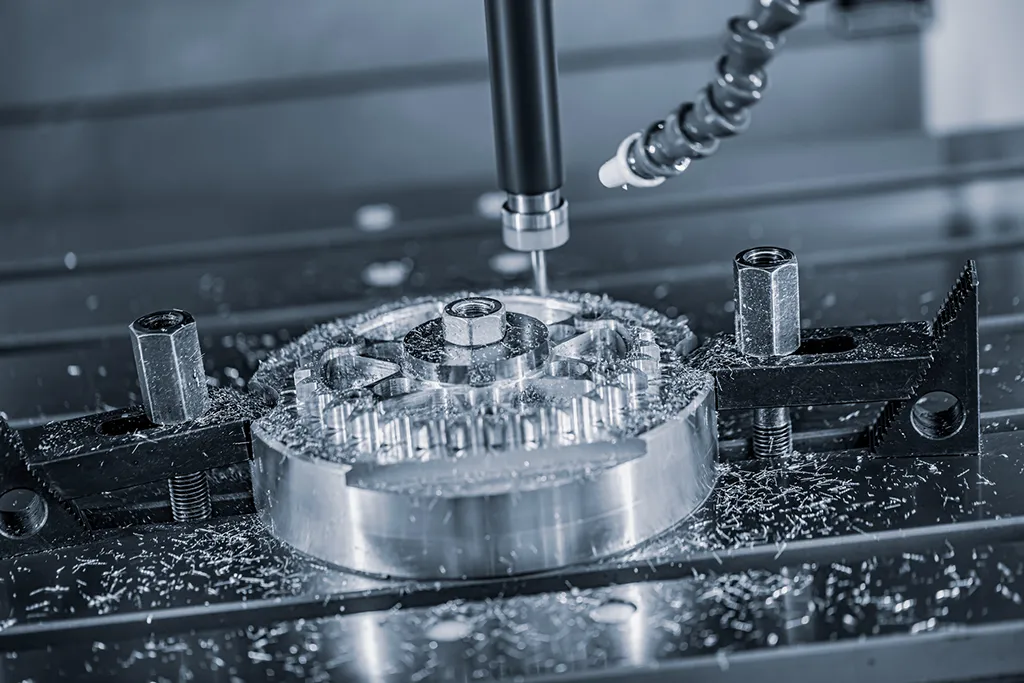

Five-axis CNC machining,As one of the core technologies of modern manufacturing,with its high precision、Advantages of high efficiency and high flexibility,Gradually becoming the key to unlocking the mystery of production efficiency。5Axis CNC machine tools are capable of controlling five axes (X、Y、Z、A、C or B、C, etc.) movement,Realize continuous processing of complex three-dimensional surfaces,Reduces the number of workpiece clamping times and processing steps,thus significantly improving production efficiency。

3.The practice of five-axis CNC machining to improve production efficiency

in practice,Five-axis CNC machining through optimized processing technology、Improve CNC programming level and strengthen equipment maintenance and upkeep and other multi-faceted strategies,Effectively improve production efficiency。For example,Through reasonable selection of cutting parameters、Optimizing machining sequences and using advanced tool materials,Can significantly reduce processing time and costs;at the same time,Use simulation software to simulate and verify the machining process,Can ensure the correctness and feasibility of the program,Reduce trial and error costs。

4.Case sharing:Successful application of five-axis CNC machining

After an automobile manufacturing company introduced five-axis CNC machining technology,,Successfully realized the continuous processing of complex parts such as engine cylinder heads,Not only greatly improves production efficiency,It also significantly improves the processing accuracy and surface quality of parts.。This successful case fully demonstrates the huge potential of five-axis CNC machining in improving production efficiency.。Looking to the future,As manufacturing becomes smarter、The development of automation,Five-axis CNC machining technology will play a more important role。It can not only meet the processing needs of complex parts,By integrating advanced sensors and intelligent algorithms,Real-time monitoring and adaptive control of the machining process,Further improve production efficiency and quality。

In this context,Rapid efficient As an industry-leading five-axis CNC machining solution provider,with its excellent performance、Stability and user-friendliness,Won the favor of many enterprises。Rapid efficient not only provides efficient processing capabilities and excellent processing accuracy,Through intelligent management systems and comprehensive after-sales services,,Provide comprehensive support and guarantee for enterprises。