In the realm of manufacturing, precision machining stands as a testament to human ingenuity and technological advancement. This intricate process involves the creation of components with unparalleled accuracy and finesse. Let’s delve into the wisdom and innovation that drive this remarkable technology.

- The Foundation of Precision

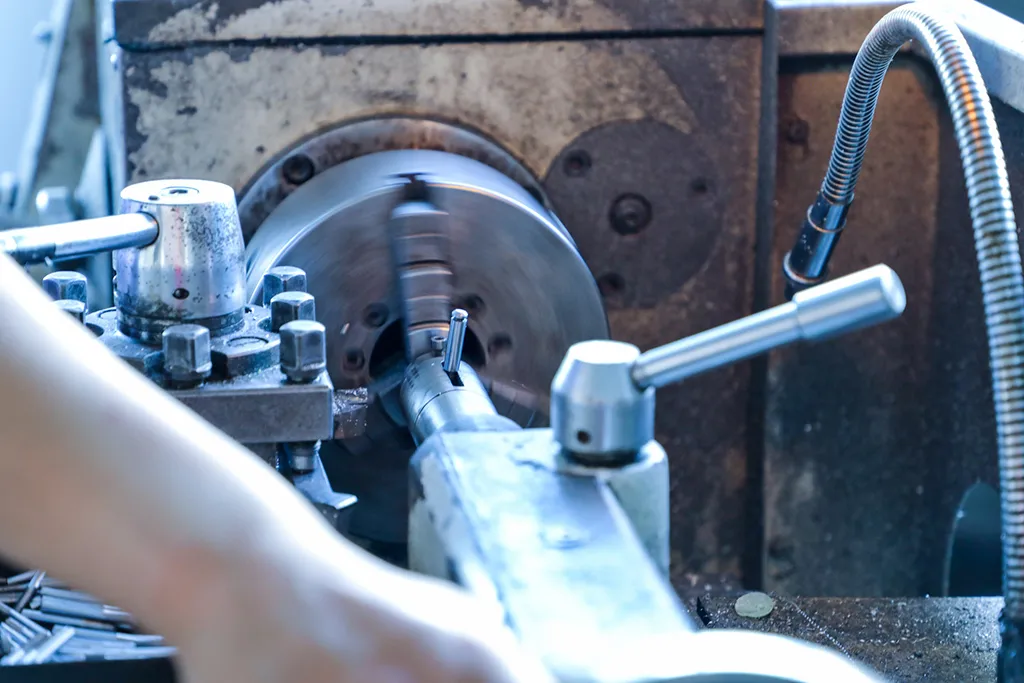

Firstly, the foundation of precision machining lies in advanced materials and cutting-edge tools. High-speed steel, carbide, and ceramic cutting tools enable machinists to achieve tolerances as tight as a few micrometers. These tools, combined with robust machinery, form the backbone of the industry.

- The Role of Technology

Secondly, technology plays a pivotal role in enhancing precision machining. Computer Numerical Control (CNC) machines have revolutionized the field by automating complex processes. With CNC, machinists can program precise movements and cuts, ensuring consistency and accuracy in every part produced.

- The Evolution of Techniques

Moreover, the evolution of machining techniques has been a cornerstone of innovation. Techniques such as grinding, milling, and turning have undergone significant refinements. For instance, five-axis machining allows for the creation of complex geometries that were previously unattainable. This technique offers greater flexibility and efficiency, pushing the boundaries of what can be achieved.

- The Integration of Smart Systems

Furthermore, the integration of smart systems and Internet of Things (IoT) technology has transformed precision machining. Real-time monitoring and data analytics enable machinists to optimize processes and reduce errors. Predictive maintenance, for example, uses data to foresee potential issues before they arise, minimizing downtime and enhancing productivity.

- The Pursuit of Perfection

The pursuit of perfection is a driving force behind precision machining. Continuous research and development lead to the creation of new materials and techniques that push the limits of accuracy. Innovations such as ultrasonic machining and laser cutting offer alternatives to traditional methods, enabling the production of even more intricate components.

- The Impact on Industries

Lastly, the impact of precision machining on various industries cannot be overstated. From aerospace to medical devices, precision-machined components are essential for the functionality and safety of countless products. The aerospace industry, for instance, relies on precision machining for parts that must withstand extreme conditions, while the medical field demands components that are both accurate and sterile.

In conclusion, precision machining embodies the wisdom and innovation that drive technological progress. From advanced tools and techniques to smart systems and the relentless pursuit of perfection, this field continues to evolve and push the boundaries of what is possible. As we look to the future, precision machining will undoubtedly play a crucial role in shaping the manufacturing landscape.