In modern manufacturing, both CNC machining and precision machining are essential processes. While they often overlap, they serve different purposes and involve distinct techniques. In this article, we’ll explore the key differences between CNC machining and precision machining, including their functions, tools, and applications.

1. Understanding CNC Machining

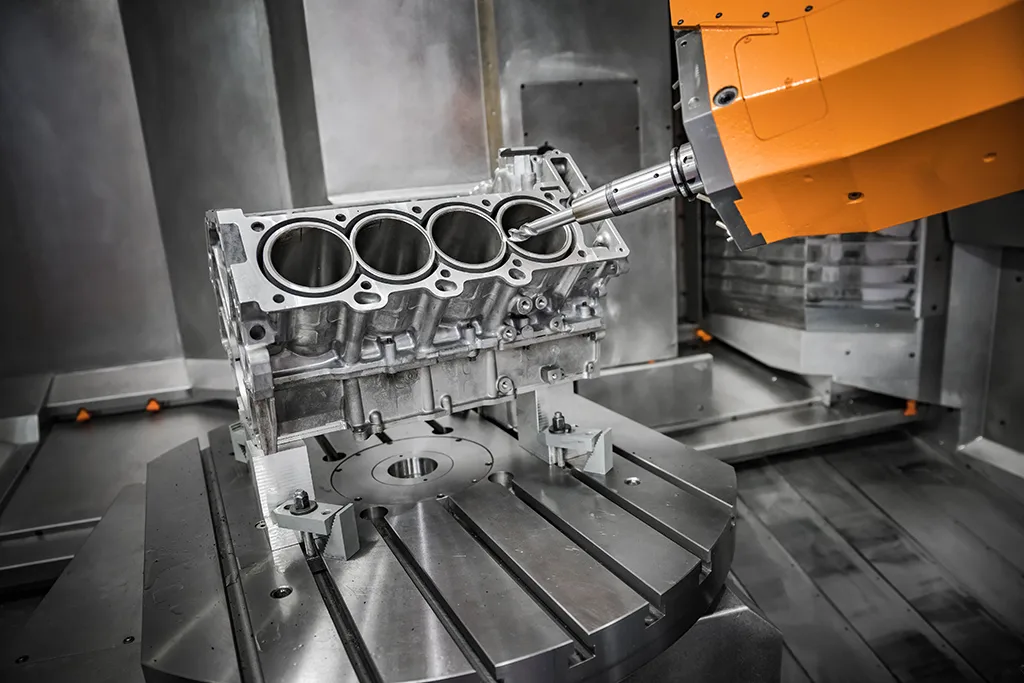

CNC (Computer Numerical Control) machining is a manufacturing process where machines are controlled by computer software. CNC machines include lathes, mills, and routers that cut, drill, or shape materials with a high degree of accuracy. The operator inputs the design into the software, and the machine follows those instructions exactly. This automation reduces the chance of human error.

CNC machining can produce both simple and complex parts. The process is highly efficient and can run continuously, making it ideal for high-volume production. Because CNC machines follow digital commands, they produce identical parts every time.

In short, CNC machining is all about automation, speed, and consistent accuracy.

2. What is Precision Machining?

Precision machining refers to the process of making parts that meet extremely tight tolerances. This means the final product closely matches the exact specifications of the design, often down to microns. Precision machining is critical for industries like aerospace, medical, and electronics, where even the slightest deviation can lead to failure.

Unlike CNC machining, which focuses on automation, precision machining prioritizes accuracy and detail. Both manual and automated machines can be used in precision machining, depending on the complexity and requirements of the part. Precision machining often uses CNC equipment, but it can also involve traditional tools like grinders and lathes.

In summary, precision machining focuses on creating highly accurate parts, regardless of the tools used.

3. CNC Machining vs. Precision Machining: The Main Difference

The key difference between CNC machining and precision machining lies in their focus. CNC machining refers to the process itself—how machines are controlled through software to automate production. Precision machining, on the other hand, is more about the quality of the output. It ensures that the parts meet tight tolerances and exact specifications.

In many cases, CNC machining is used within precision machining. For example, manufacturers may use CNC machines to produce highly precise components for medical devices or aerospace parts. However, not all CNC machining requires precision. Sometimes, CNC machines are used for parts that don’t demand such strict accuracy.

To put it simply, CNC machining is a method, while precision machining is a standard of accuracy.

4. Tools Used in CNC Machining and Precision Machining

Both CNC machining and precision machining use advanced equipment, but the focus differs. CNC machining heavily relies on computer-controlled machines like CNC mills, routers, and lathes. These machines operate automatically and with high speed. They are programmed to follow exact paths and instructions, ensuring consistency in every part produced.

Precision machining, on the other hand, may use a wider range of tools. CNC machines are often part of precision machining, but other equipment like grinders, electrical discharge machines (EDM), and manual lathes may also be used. These tools allow for even finer adjustments when accuracy is essential.

In short, CNC machines are the primary tools in CNC machining, while precision machining utilizes both CNC and manual tools depending on the need for accuracy.

5. Applications of CNC Machining and Precision Machining

CNC machining is commonly used in industries that require high-volume production. Automotive, electronics, and consumer goods manufacturers rely on CNC machines for quick and consistent production. These industries benefit from the speed and automation of CNC machines, especially when producing large quantities of the same part.

Precision machining, on the other hand, is often used in industries where quality is critical. Aerospace, medical, and defense sectors rely heavily on precision machining to produce parts that meet strict standards. For instance, medical implants or aircraft components must be extremely accurate to ensure safety and performance.

While CNC machining can be part of precision machining, not all CNC processes need to meet the high tolerances required in precision machining.

6. Cost and Efficiency

CNC machining is generally more efficient for high-volume production. Once programmed, CNC machines can run continuously, producing parts quickly and consistently. This makes CNC machining a cost-effective solution for manufacturers who need large quantities of parts in a short period.

Precision machining, however, tends to focus more on quality than speed. The process often takes more time to ensure that each part meets the required tolerances. This attention to detail can make precision machining more expensive, especially for small batches of parts. However, for industries where accuracy is essential, the higher cost is worth it.

In summary, CNC machining excels in efficiency and cost for mass production, while precision machining prioritizes quality and accuracy, often at a higher cost.

Conclusion

CNC machining and precision machining serve different roles in manufacturing. CNC machining automates the process, focusing on speed and consistency, while precision machining emphasizes the quality and accuracy of the final product. In many cases, CNC machining is a key tool within precision machining, but not all CNC processes require the tight tolerances of precision work.

Understanding the differences between these two processes helps manufacturers choose the right method based on their production needs. Whether it’s mass production with CNC machining or highly accurate part creation with precision machining, both play critical roles in today’s industrial landscape.