Laser cutting technology is rapidly evolving, driven by demand for efficiency, precision, and versatility. From automation to AI integration, advancements are transforming how industries use laser cutting. This article explores key trends in laser cutting development and their impact on manufacturing and beyond.

1. Increased Automation

Automation is a major trend in laser cutting. Manufacturers are adopting automated systems to improve speed and accuracy. Automated laser cutting machines can handle large production runs with minimal manual intervention. These systems load, cut, and unload materials automatically, reducing labor costs and production time. With automation, industries can meet tight deadlines and scale production without sacrificing quality.

2. Integration of AI and Machine Learning

Artificial intelligence (AI) and machine learning are shaping the future of laser cutting. AI-enhanced systems can analyze data from previous cuts, optimizing settings for precision and speed. Machine learning algorithms allow laser cutters to learn from past projects and improve over time. This smart technology also helps detect potential issues early, reducing downtime and material waste. With AI, manufacturers can achieve consistent quality and higher productivity.

3. Advanced Laser Sources for Higher Power

As technology progresses, laser sources are becoming more powerful. High-power lasers enable faster cutting of thick and hard materials, like steel and titanium. These advanced laser sources reduce cutting time and increase productivity, especially in industries with heavy materials. Fiber lasers, known for their efficiency and power, are particularly popular. Their high-speed capabilities and precision make them ideal for automotive, aerospace, and construction applications.

4. Enhanced Precision and Accuracy

Precision is crucial in industries like electronics and aerospace. New laser cutting machines offer higher accuracy than ever before. Advanced control systems allow for micro-level adjustments, ensuring each cut is precise. The demand for miniaturized components drives the need for this high precision. This trend has led to the development of fine-tuned lasers capable of producing intricate designs without compromising quality.

5. Versatility Across Diverse Materials

Laser cutting technology now handles a wider range of materials. From metals and plastics to glass and ceramics, lasers are becoming more versatile. Innovations allow lasers to cut, engrave, or etch various materials with equal precision. This versatility helps companies use one machine for multiple applications, reducing costs and improving efficiency. With evolving technology, laser cutting systems continue to expand their material compatibility, enabling more complex projects.

6. Cost-Efficiency with Higher Energy Savings

As energy efficiency becomes a priority, laser cutting systems are advancing in this area too. Modern lasers consume less energy than traditional systems, lowering operational costs. Manufacturers can cut materials faster, reducing energy use per unit produced. Fiber lasers, in particular, are highly energy-efficient, making them a cost-effective choice. By reducing power consumption, companies benefit financially while contributing to sustainability goals.

7. Compact and Modular Machine Designs

With space at a premium, manufacturers are seeking more compact machines. Laser cutting systems are now available in modular, space-saving designs. Compact systems offer the same power and precision as larger machines but take up less room. Modular designs allow for easy customization and scalability. This trend benefits small businesses, as they can integrate laser cutting without needing extensive space or equipment.

8. Improved Safety and Environmentally Friendly Technology

Safety and sustainability are critical in modern manufacturing. Today’s laser cutting machines come equipped with improved safety features, such as enclosed work areas and automated shut-offs. Many systems now meet environmental standards by minimizing emissions and waste. Laser cutting produces less debris and harmful byproducts compared to traditional methods. These eco-friendly benefits make laser cutting an attractive option for companies focused on safety and environmental impact.

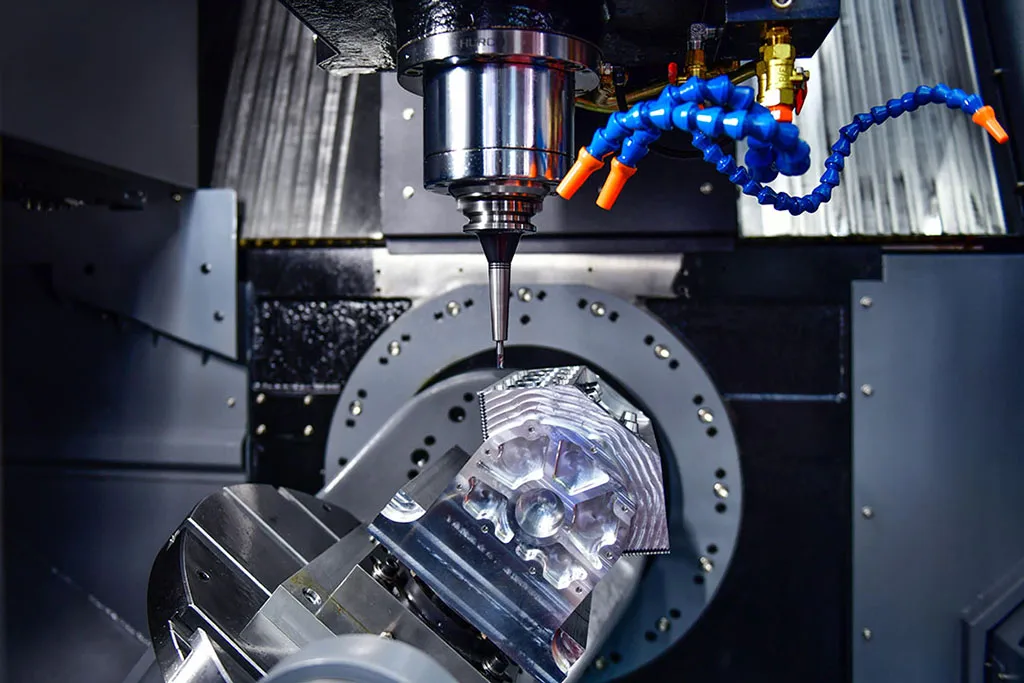

9. 3D Laser Cutting for Complex Shapes

3D laser cutting is becoming more popular as demand grows for complex designs. Unlike traditional 2D cutting, 3D laser systems cut along multiple axes, enabling intricate shapes and angles. This capability is invaluable in industries like aerospace, automotive, and medical device manufacturing. With 3D laser cutting, manufacturers can produce more complex parts without additional tooling, saving time and resources.

10. Remote Monitoring and Maintenance

Remote monitoring has become essential for efficient operations. Modern laser cutting systems now feature IoT-enabled sensors that track performance in real-time. These systems alert operators to maintenance needs or potential issues, preventing downtime. Remote access allows technicians to monitor machines from anywhere, making maintenance faster and more efficient. This trend minimizes interruptions, helping manufacturers maintain steady production.

Conclusion

The development trends in laser cutting point toward a future of efficiency, precision, and versatility. From AI integration to 3D cutting capabilities, these advancements make laser cutting more valuable than ever. Manufacturers now benefit from automation, energy savings, and compact designs, which allow for flexible and sustainable production. As laser technology continues to evolve, industries can look forward to even more innovative applications and benefits. These trends are shaping the future of manufacturing, ensuring that laser cutting remains at the forefront of modern production methods.