In the vast world of manufacturing, precision hardware parts play a vital role. They not only support the normal operation of various mechanical equipment, but also promote the progress of science and technology and the development of industry. So, what are the advantages of precision hardware parts? The following will be elaborated in detail from several aspects.

1. High precision and high quality

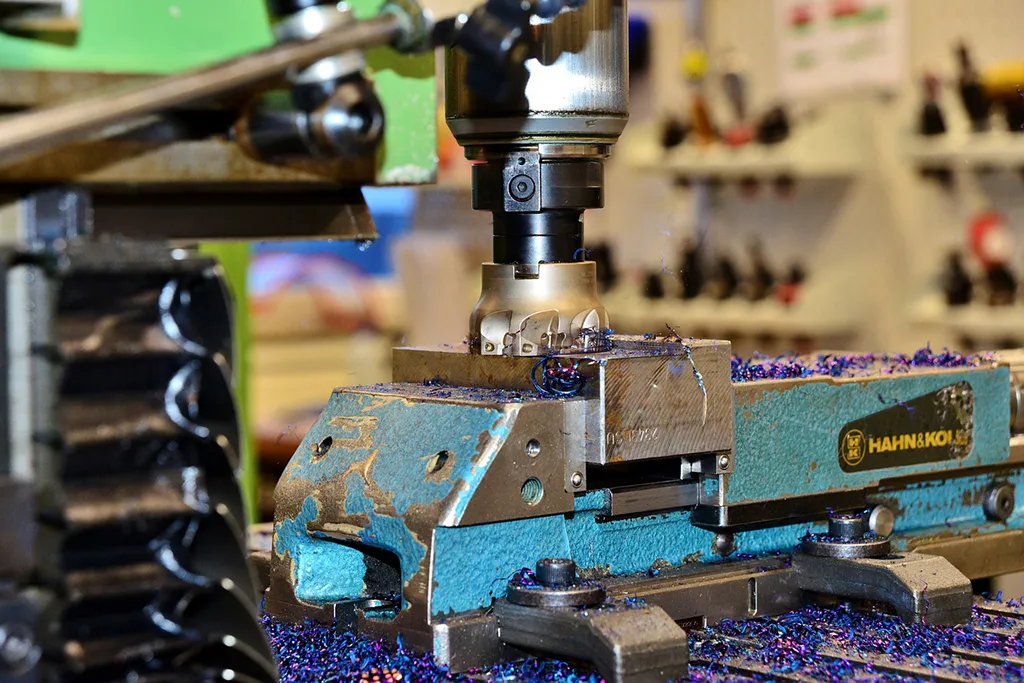

The biggest feature of precision hardware parts is their high precision. In the production process, through advanced processing technology and strict quality control, it can be ensured that the size, shape and surface quality of the parts meet extremely high standards. This high precision not only improves the performance of the product, but also extends the service life and reduces maintenance costs.

High quality is undoubtedly another highlight of precision hardware parts. Thanks to the selected high-quality raw materials and advanced production processes, these parts have shown excellent performance in multiple dimensions such as strength, hardness and wear resistance. Because of this, even under extremely harsh working conditions, precision hardware parts can remain stable as before, ensuring the smooth operation of the equipment.

2. High production efficiency

The production of precision hardware parts usually adopts automated and mechanized production methods. This production method not only improves production efficiency, but also reduces labor costs. At the same time, due to the use of advanced processing technology, the production cycle of parts is greatly shortened, and market demand can be quickly responded to.

In addition, the production of precision hardware parts also demonstrates extremely high flexibility. Only by slightly adjusting the production parameters and process flow, various specifications and models of parts can be easily manufactured, so as to accurately meet the personalized customization needs of customers.

3. Strong interchangeability

The interchangeability of precision hardware parts is another major advantage. Due to the use of standardized production processes and strict quality control, parts produced in the same batch or different batches are consistent in size, shape and quality. This interchangeability not only facilitates the replacement and maintenance of parts, but also improves the reliability and stability of equipment.

Due to their high interchangeability, precision hardware parts show great convenience in repair and maintenance. Once the equipment fails, only the damaged parts need to be replaced to quickly restore the normal operation of the equipment without the need to disassemble and repair the entire equipment.

4. Wide range of applications

The application field of precision hardware parts is very wide. They are not only widely used in high-tech fields such as automobiles, electronics, aerospace, etc., but also penetrate into people’s daily lives. For example, engine parts on cars, shells and internal structural parts of electronic products, precision instruments in the aerospace field, etc., all rely on the support of precision hardware parts.

In addition, with the increasing advancement of science and technology and the vigorous development of industry, the application scope of precision hardware parts continues to expand. Especially in emerging fields such as new energy and intelligent manufacturing, they are playing an increasingly critical and important role.

5. Conclusion

In summary, precision hardware parts have the advantages of high precision and high quality, high production efficiency, strong interchangeability and a wide range of applications. These advantages make precision hardware parts play a pivotal role in the manufacturing industry. In the future, with the advancement of science and technology and the development of industry, the application prospects of precision hardware parts will be broader.