In the vast field of modern manufacturing, CNC machine tools play a vital role. Among them, CNC milling machines and CNC lathes are particularly prominent, widely used and highly efficient, and are the two most commonly used types of machine tools. Next, we will elaborate on these two types of machine tools from multiple aspects.

一. CNC lathe

CNC lathes are mainly used to process rotating parts such as shafts and disks. Its working principle is that the workpiece rotates, and the tool moves along a straight line or curve for cutting. This processing method gives CNC lathes significant advantages in processing internal and external cylindrical surfaces, conical surfaces, and threads.

1. Diverse functions: CNC lathes can not only perform turning processing, but also drilling, tapping, knurling and other operations, meeting the diverse needs of parts processing.

2. High precision: Due to the use of CNC technology, the processing accuracy of CNC lathes has been significantly improved, which can meet the processing requirements of high-precision parts.

3. High efficiency: CNC lathes usually use automatic loading and unloading and automatic tool changing devices, which greatly shortens the processing cycle and improves production efficiency.

二. CNC milling machine

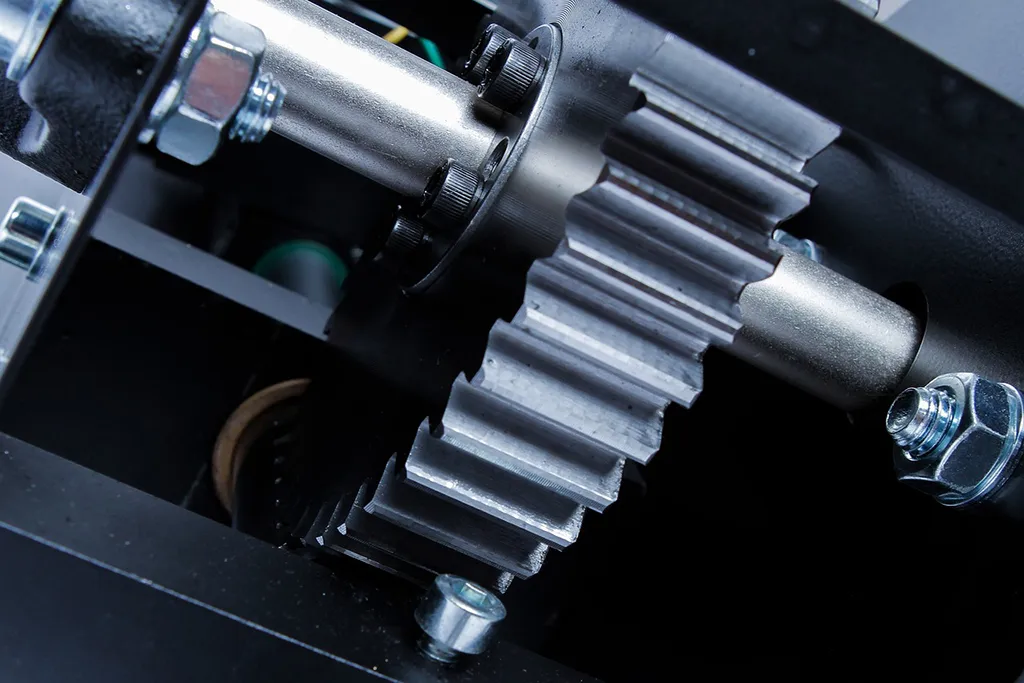

CNC milling machines are mainly used to process parts with complex shapes such as planes, grooves, and curved surfaces. Its working principle is that the tool rotates, while the blank or workpiece is fixed, and the tool moves along a straight line or curve for cutting.

1. Wide processing range: CNC milling machines can process parts of various shapes, including planes, grooves, gears, spiral surfaces, etc., which makes it widely used in mold manufacturing, aerospace and other fields.

2. Strong ability to process complex shapes: Compared with CNC lathes, CNC milling machines have more advantages in processing complex shapes, and can process various irregular surfaces and special molding surfaces.

3. Strong adaptability: CNC milling machines usually adopt modular design, and different tools and accessories can be selected according to needs to adapt to different materials and different processing requirements.

三. Comparison between CNC lathes and CNC milling machines

Although CNC lathes and CNC milling machines differ in processing methods and scope of application, they are both indispensable processing equipment in modern manufacturing. CNC lathes are more suitable for processing rotating parts, while CNC milling machines are more suitable for processing parts with complex shapes. In practical applications, it is often necessary to select suitable machine tools according to the shape, material and processing requirements of the parts.

In addition, with the continuous development of science and technology, the functions and performance of CNC machine tools are also constantly improving. For example, three-dimensional CNC machine tools can perform more complex three-dimensional processing, while multi-axis CNC machine tools can meet the processing needs of high precision and high complexity. The emergence of these new CNC machine tools has further promoted the development and progress of the manufacturing industry.

CNC lathes and CNC milling machines play an important role in modern manufacturing and are the most commonly used CNC machine tools. They not only improve production efficiency, but also ensure the high precision and high quality of products. With the continuous advancement of technology and the continuous development of the market, the application prospects of CNC machine tools will be broader.