Precision hardware parts, as an important part of modern industry, are widely used in various fields, with various types and characteristics. This article will give a detailed introduction to the classification of precision hardware parts to help everyone better understand this field.

一. Classification by material

1. Stainless steel parts: corrosion-resistant, heat-resistant and high-strength.

An ideal material for the manufacture of precision hardware parts. Such parts are widely used in many key fields such as medical equipment, food processing and chemical industry.

2. Aluminum alloy parts: low density, high strength and corrosion resistance.

They shine in aerospace, automobile manufacturing, electronic equipment and other fields, effectively reducing weight and improving overall operating efficiency.

3. Copper alloy parts: strong electrical and thermal conductivity, corrosion resistance.

Commonly used in electrical connectors, radiators and water supply pipes.

二. Classification by use

1. Auto parts: engine parts, transmission system parts, suspension system parts, etc.

In automobile manufacturing, precision hardware parts play a vital role.

2. Electronic equipment parts: With the popularity of electronic products, precision hardware parts are increasingly used in electronic equipment. For example, mobile phone housings, circuit board brackets, sensors, etc. are all indispensable components of electronic equipment.

3. Aerospace parts: The aerospace field has extremely high requirements for the precision and reliability of parts. Precision hardware parts such as engine blades and flight control system parts are the key to the normal operation of aerospace equipment.

三. Classification by shape and process

1. Stamping parts: Using stamping technology, it has the characteristics of complex shape, precise size and high production efficiency. Such parts are often used in automotive parts, home appliance accessories, etc.

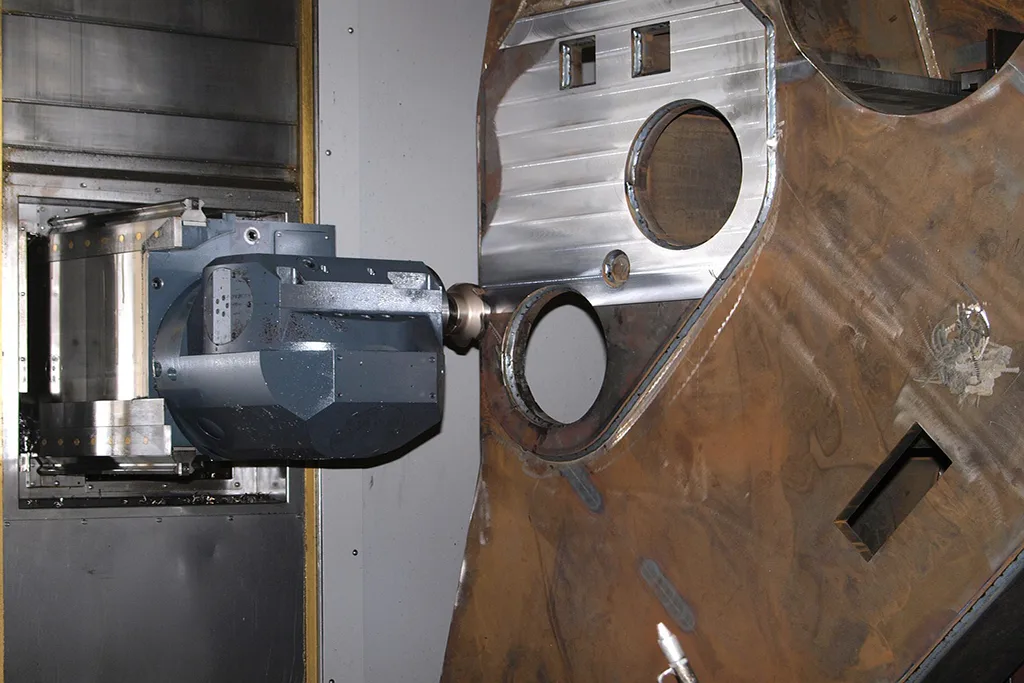

2. Casting parts: Using casting technology, it is suitable for manufacturing large, complex and difficult-to-process parts. Such as engine cylinders, gearbox housings, etc.

3. Machined parts: Using machining methods such as turning, milling, planing, and grinding. These parts have the characteristics of high precision and high surface quality, and are often used in precision instruments, medical equipment, etc.

四. Classification by industry specific

1. Medical equipment parts: such as surgical instruments, diagnostic equipment, etc., require extremely high precision and reliability to ensure medical safety and effectiveness.

2. Watch parts: such as gears, springs, etc., require extremely high precision and stability to ensure the accuracy and reliability of watches.

In short, there are many categories of precision hardware parts, each with its own characteristics, and they play an irreplaceable role in their respective application fields. A deep understanding of these categories will enable us to more accurately select parts that meet specific needs.