In the automotive industry, precision is paramount. Mechanical machining services for automotive play a critical role in producing high-quality components that meet strict performance and safety standards. From engine parts to complex transmission systems, precision machining ensures reliability, durability, and efficiency in every vehicle on the road.

The Role of Mechanical Machining in Automotive Manufacturing

Mechanical machining is essential for creating intricate parts with tight tolerances, ensuring seamless performance in critical automotive systems. Here are some of its core applications:

1. Engine Components

Precision-machined parts like cylinder heads, pistons, and crankshafts ensure optimal engine performance. These components must meet exact specifications to handle high stress and temperature conditions.

2. Transmission Systems

Gears, shafts, and housings require impeccable accuracy for smooth operation. Poorly machined parts can lead to transmission failures and costly repairs.

3. Suspension and Brake Systems

Mechanical machining ensures that suspension arms, brake calipers, and rotors are durable and reliable, improving safety and vehicle stability.

4. Electric Vehicle (EV) Components

With the rise of EVs, machining services are increasingly focused on battery enclosures, motor housings, and thermal management systems to support next-generation mobility.

Benefits of Precision Machining for Automotive Applications

1. High-Quality Outputs

Machined components meet exacting standards, reducing the risk of defects and ensuring longer-lasting parts.

2. Cost Efficiency

While upfront costs may be higher, precision machining minimizes wastage and reduces the need for frequent replacements, saving money in the long run.

3. Enhanced Performance

Accurate parts improve the overall efficiency and safety of automotive systems, leading to better performance and customer satisfaction.

4. Customization

Advanced machining technologies allow for bespoke solutions, catering to specific designs and requirements.

Why Rapidefficient is Your Trusted Partner

In the competitive automotive industry, choosing the right machining partner can make all the difference. Rapidefficient has established itself as a leader in delivering mechanical machining services for automotive. Here’s why:

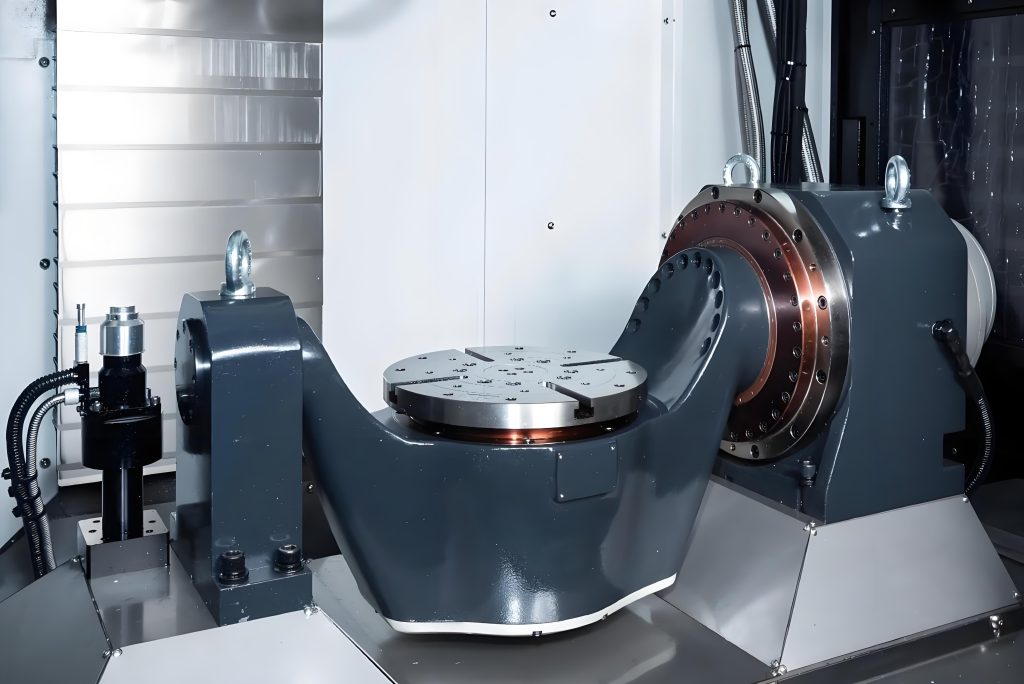

1. Advanced CNC Technology

Rapidefficient employs cutting-edge CNC machines to deliver high-precision parts that meet the stringent demands of the automotive sector.

2. Skilled Professionals

Their team of experienced engineers ensures every project is executed with expertise and attention to detail.

3. Fast Turnaround

Rapidefficient’s streamlined processes guarantee timely delivery without compromising quality, keeping your production schedules on track.

4. Commitment to Quality

From material selection to final inspection, Rapidefficient upholds rigorous quality control measures to ensure flawless results.

5. Eco-Friendly Practices

As sustainability becomes a priority, Rapidefficient incorporates energy-efficient operations and minimizes material waste.

Challenges in Automotive Machining

Despite its advantages, mechanical machining for automotive components comes with challenges:

- Material Hardness: Automotive-grade materials like titanium and carbon steel require specialized tools and techniques.

- Complex Geometries: Modern automotive designs demand intricate parts that can only be achieved through advanced machining.

- Volume and Consistency: High production volumes require consistent quality, which is where Rapidefficient excels.

Choosing Rapidefficient for Your Machining Needs

When precision and reliability matter, Rapidefficient is the ultimate choice for mechanical machining services for automotive. Their dedication to innovation and customer satisfaction sets them apart as a trusted partner in the CNC machining market.

From small-scale projects to large production runs, Rapidefficient delivers unmatched quality and value. Contact them today to learn how they can enhance your automotive manufacturing process.