1. Core Viewpoints

1.1 Key Manufacturing Technology Driving Aerospace Development

Aerospace CNC aluminum machining is of crucial significance in the aerospace field. It is the key technology for manufacturing high – precision components. With the increasing requirements for the performance and reliability of aerospace equipment, the precision and quality of components directly affect the overall performance of the aircraft. CNC aluminum machining technology enables the production of parts with extremely high precision, meeting the strict demands of the aerospace industry.

1.2 Co – existence of Opportunities and Challenges, Leading Industrial Transformation

This technology brings numerous development opportunities. For example, it allows for the creation of more advanced and efficient aerospace components, enhancing the competitiveness of aerospace products. However, it also faces challenges. Technological innovation requires continuous investment in research and development, and there are issues such as the need to adapt to rapidly changing design requirements. These challenges have a significant impact on the future transformation of the industry.

1.3 Huge Investment Potential and Prominent Strategic Value

In the investment field, aerospace CNC aluminum machining has great potential. As the aerospace industry continues to expand, the demand for related machining services will increase. Its strategic value lies in its ability to support the development of the aerospace industry, ensuring the supply of high – quality components and contributing to national aerospace security and development.

2. Market Analysis

2.1 Driving Factors of Industry Demand

2.1.1 Expansion of the Aerospace Industry

The continuous development of the aerospace industry has led to a growing demand for high – precision components. The increase in the number of aircraft production, the development of new models, and the expansion of space exploration activities all require a large number of precisely machined aluminum parts. This has become a strong driving force for the development of the aerospace CNC aluminum machining market.

2.1.2 Promotion by Technological Progress

Advanced numerical control technology and progress in materials science provide more powerful technical support. The improvement of CNC machine tools in terms of precision, speed, and flexibility, combined with the development of new aluminum alloys with better performance, enables more efficient and high – quality machining processes.

2.2 Market Size and Growth Trend

2.2.1 Evaluation of Current Market Size

Globally, the market size of aerospace CNC aluminum machining has been steadily increasing. In developed countries with advanced aerospace industries, such as the United States and Europe, there are a large number of specialized machining enterprises with high – volume production capabilities. In the domestic market, with the rise of the aerospace industry, the market size is also expanding rapidly, and more and more domestic enterprises are entering this field.

2.2.2 Future Growth Forecast

Based on industry development trends, the market is expected to maintain a relatively high growth rate in the future. The continuous development of new aerospace projects, the improvement of machining technology, and the expansion of international cooperation will contribute to market growth.

2.3 Market Competition Pattern

2.3.1 Analysis of Major Participants

The main players in this field include traditional aerospace manufacturing enterprises and specialized machining companies. Traditional aerospace giants have strong R & D capabilities, extensive production experience, and stable customer resources. Specialized machining enterprises, on the other hand, often have unique technical advantages in CNC machining, focusing on providing high – quality machining services.

2.3.2 Comparison of Competitive Advantages

These enterprises’ competitive advantages vary. Some companies rely on advanced technology, such as using the latest CNC machine tools and software to achieve higher precision machining. Others focus on product quality control, ensuring that each machined part meets strict aerospace standards. Service level is also an important factor, including on – time delivery, after – sales service, and customized solutions for customers.

3. Product Research

3.1 Characteristics of Machining Process

3.1.1 High – precision Machining Capability

Aerospace CNC aluminum machining has outstanding high – precision machining characteristics. Through advanced control systems, high – precision measuring tools, and precise cutting tools, it can achieve micron – level machining accuracy. For example, in the processing of key components such as turbine blades, extremely high precision is required to ensure the performance and reliability of the engine.

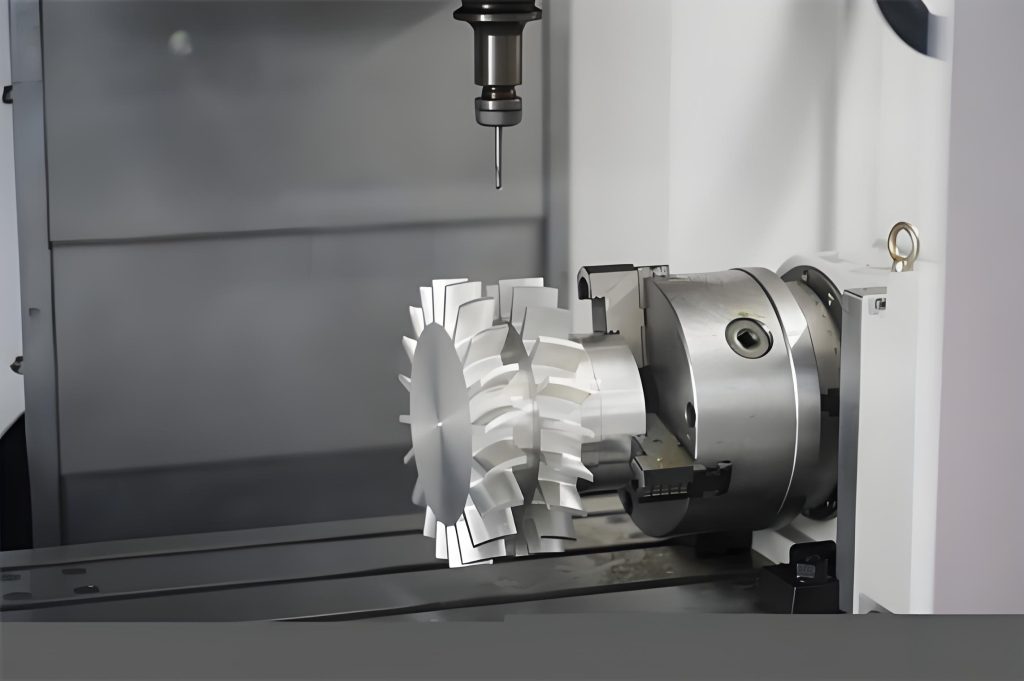

3.1.2 Advantage in Machining Complex Shapes

It has unique advantages in machining complex – shaped parts. The flexibility of CNC programming allows for the creation of various complex geometric shapes. In the design of modern aerospace structures, there are many components with complex curves and irregular shapes, and this machining technology can meet these requirements well.

3.2 Application Areas of Products

3.2.1 Components of Aero – engines

In the manufacturing of aero – engine components, aerospace CNC aluminum machining plays a vital role. Engine casings, blades, and shafts often require high – strength, lightweight aluminum materials and precise machining. These components directly affect the performance, fuel efficiency, and reliability of the engine.

3.2.2 Fuselage Structural Components

For fuselage structural components, machining technology is used to produce parts with high strength and low weight. The accurate processing of frame members, skin panels, and other components ensures the overall structural integrity and safety of the aircraft.

4. Competition Pattern

4.1 Enterprise Competition Strategies

4.1.1 Driven by Technological Innovation

Enterprises enhance their competitiveness through continuous technological innovation. They invest in research and development of new machining processes, improve the performance of machine tools, and develop advanced software for CNC programming. By introducing new technologies such as additive – subtractive hybrid manufacturing, they aim to gain an edge in the market.

4.1.2 Improvement of Service Quality

High – quality service is crucial in competition. This includes ensuring on – time delivery of products, providing comprehensive after – sales service, and being able to quickly respond to customer needs. Customized solutions for different customer requirements also help enterprises win more business opportunities.

4.2 Distribution of Market Share

4.2.1 Global Market Pattern

Globally, a few large aerospace manufacturing groups and specialized machining enterprises dominate the market. They have extensive production facilities and global sales networks, accounting for a large proportion of the market share. However, with the development of emerging economies, some local enterprises are gradually emerging and challenging the traditional market structure.

4.2.2 Domestic Market Situation

In the domestic market, there are also leading enterprises with certain market shares. These enterprises are constantly strengthening their capabilities through technology introduction and independent innovation. At the same time, competition among domestic enterprises is becoming increasingly fierce, promoting the improvement of the overall industry level.

5. Regulatory Policy

5.1 Aerospace Industry Regulation

5.1.1 Quality Standard Requirements

The aerospace industry has extremely strict quality standards for component machining. These standards cover various aspects such as dimensional accuracy, material properties, and surface quality. Parts must undergo a series of strict inspections and tests to ensure they meet the requirements for use in aerospace applications.

5.1.2 Safety Certification Specifications

Safety is of utmost importance in the aerospace industry. Relevant safety certification specifications require that machining processes and products comply with strict safety regulations. This includes ensuring the reliability of components under extreme conditions and preventing potential safety hazards during the operation of aircraft.

5.2 Impact of Numerical Control Machining Policy

5.2.1 Guidance of Technological Development

Government policies play a guiding role in the development of CNC machining technology. They encourage enterprises to invest in research and development of advanced machining technology, support the development of key technologies, and promote the application of new technologies in the aerospace industry.

5.2.2 Industrial Support Measures

The government has implemented a series of industrial support measures for aerospace CNC aluminum machining. This includes financial subsidies for enterprises’ R & D activities, tax incentives, and the construction of industrial parks to promote the agglomeration and development of the industry.

6. Other Influencing Factors

6.1 Stability of Material Supply

6.1.1 Fluctuations in the Aluminum Alloy Market

The aluminum alloy market is subject to fluctuations, which have an impact on the machining industry. Changes in aluminum prices, supply shortages, or quality variations of raw materials can affect production costs and product quality. Enterprises need to establish stable supply chains to cope with these market fluctuations.

6.1.2 Supply Chain Risk Management

To ensure the stable supply of materials, effective supply chain risk management is essential. This includes diversifying suppliers, establishing inventory management systems, and closely monitoring market dynamics to minimize the impact of potential supply disruptions.

6.2 Talent Demand and Cultivation

6.2.1 Shortage of Professional and Technical Talents

Currently, there is a shortage of professional and technical talents in the field of aerospace CNC aluminum machining. Skilled operators, engineers with in – depth knowledge of CNC programming and aerospace manufacturing, and R & D personnel are in high demand. The lack of such talents restricts the development speed of the industry.

6.2.2 Talent Cultivation Strategies

To address the talent shortage issue, various talent cultivation strategies can be adopted. This includes strengthening cooperation between enterprises and educational institutions, establishing vocational training programs, and providing on – job training opportunities to improve the professional skills of employees.

7. Risk Analysis

7.1 Technical Risk

7.1.1 Challenge of Technological Upgrading

The rapid technological upgrading in the field of aerospace CNC aluminum machining poses a challenge to enterprises. New machining technologies and materials are constantly emerging. If enterprises cannot keep up with the pace of technological progress, their products may become obsolete, and they may lose their competitive advantage.

7.1.2 Risk of Technological R & D Failure

During the process of technological R & D, there are many risks. The investment in R & D may not yield the expected results, and new technologies may face difficulties in implementation due to various reasons such as technical complexity and high costs.

7.2 Market Risk

7.2.1 Impact of Demand Fluctuations

Market demand for aerospace products is subject to fluctuations. Economic cycles, changes in government policies, and international trade situations can all affect the demand for aerospace equipment. This, in turn, affects the demand for CNC aluminum machining services, leading to fluctuations in enterprise business performance.

7.2.2 Pressure from Intensified Competition

With the continuous entry of new enterprises into the market, competition is intensifying. Competitors may adopt price – cutting strategies or introduce more advanced technologies, putting pressure on existing enterprises. This may lead to a reduction in profit margins and market share.

7.3 Policy Risk

7.3.1 Change in Regulatory Policy

Changes in regulatory policies can have a significant impact on enterprises. Stricter quality and safety standards may require enterprises to make additional investments in production processes and quality control. Changes in environmental protection policies may also affect the choice of materials and production processes.

7.3.2 Uncertainty of Trade Policy

Trade policy uncertainties, such as trade disputes and tariff adjustments, can disrupt the international supply chain and market environment. For aerospace CNC aluminum machining enterprises with international business, this may lead to changes in import and export costs, market access, and customer orders.