ABSTRACT

This paper discusses the importance of CNC aluminum machining in modern manufacturing. It elaborates on the research background and purpose, presents in detail the working principle of CNC machining and the key points of aluminum material selection. It analyzes the advantages of CNC aluminum machining such as high precision, consistency, automation and flexibility, as well as its extensive applications in industries such as aerospace and automotive. It looks forward to the future development trends of CNC aluminum machining, including technology integration, adaptation to new materials and green manufacturing. It also emphasizes the important factors in choosing an efficient CNC aluminum processing service provider.

1、Introduction

1.1 Research Background

In today’s rapidly evolving manufacturing landscape, CNC aluminum machining has emerged as a crucial process with growing importance. The modern manufacturing industry is characterized by a demand for high precision, complex designs, and efficient production methods. CNC aluminum machining meets these requirements, playing a vital role in various sectors.

The aerospace industry, for example, relies on CNC aluminum machining to produce lightweight yet strong components for aircraft. The use of aluminum in aerospace offers several benefits, including reduced weight, which leads to lower fuel consumption and increased payload capacity. With CNC machining, intricate parts can be manufactured with extreme precision, ensuring the safety and performance of aircraft.

In the medical equipment sector, CNC aluminum machining is essential for creating components that must meet strict quality and precision standards. Medical devices often require complex shapes and tight tolerances, and CNC machining can deliver these with consistency.

The automotive industry also benefits from CNC aluminum machining. As the demand for lighter and more fuel-efficient vehicles grows, aluminum is becoming an increasingly popular material. CNC machining allows for the production of complex aluminum parts for engines, transmissions, and body panels.

Furthermore, in the electronics industry, CNC aluminum machining is used to create enclosures and heat sinks. The precision and durability of aluminum parts made through CNC machining are crucial for protecting sensitive electronic components and ensuring proper heat dissipation.

In conclusion, CNC aluminum machining is of growing importance in modern manufacturing due to its ability to produce high-quality, complex parts with precision and efficiency, serving a wide range of industries from aerospace to electronics.

1.2 Research Purpose

CNC aluminum machining offers several significant benefits and has diverse applications across different industries.

One of the major benefits is precision. With advanced CNC technology, it is possible to achieve extremely tight tolerances, often within a few thousandths of an inch. This level of precision is crucial in industries like aerospace, where even the slightest deviation can have a significant impact on the performance and safety of an aircraft. For example, in the production of aircraft components, CNC aluminum machining ensures that each part fits perfectly, reducing the risk of failure and enhancing the overall reliability of the aircraft.

Another benefit is efficiency. CNC machines can operate continuously, reducing production time and increasing output. In the automotive industry, this efficiency is essential as manufacturers strive to meet the growing demand for lighter and more fuel-efficient vehicles. By using CNC aluminum machining, complex parts can be produced quickly and accurately, enabling faster assembly and reducing production costs.

In addition to precision and efficiency, CNC aluminum machining also offers flexibility. The same machine can be programmed to produce a wide variety of parts with different shapes and sizes. This is particularly useful in the electronics industry, where product designs often change rapidly. With CNC aluminum machining, manufacturers can quickly adapt to new designs and produce parts that meet the specific requirements of different electronic devices.

The applications of CNC aluminum machining are extensive. In addition to the aerospace, medical, automotive, and electronics industries mentioned earlier, it is also used in industrial automation equipment, building, and rail transit. For example, in industrial automation, CNC aluminum machining is used to produce precision parts for robots and other automated systems. In the building industry, aluminum components made through CNC machining are used for decorative elements and structural support.

In conclusion, CNC aluminum machining provides numerous benefits, including precision, efficiency, and flexibility. Its applications span a wide range of industries, making it an essential process in modern manufacturing.

2、Theoretical Basis

2.1 Working Principle of CNC Machining

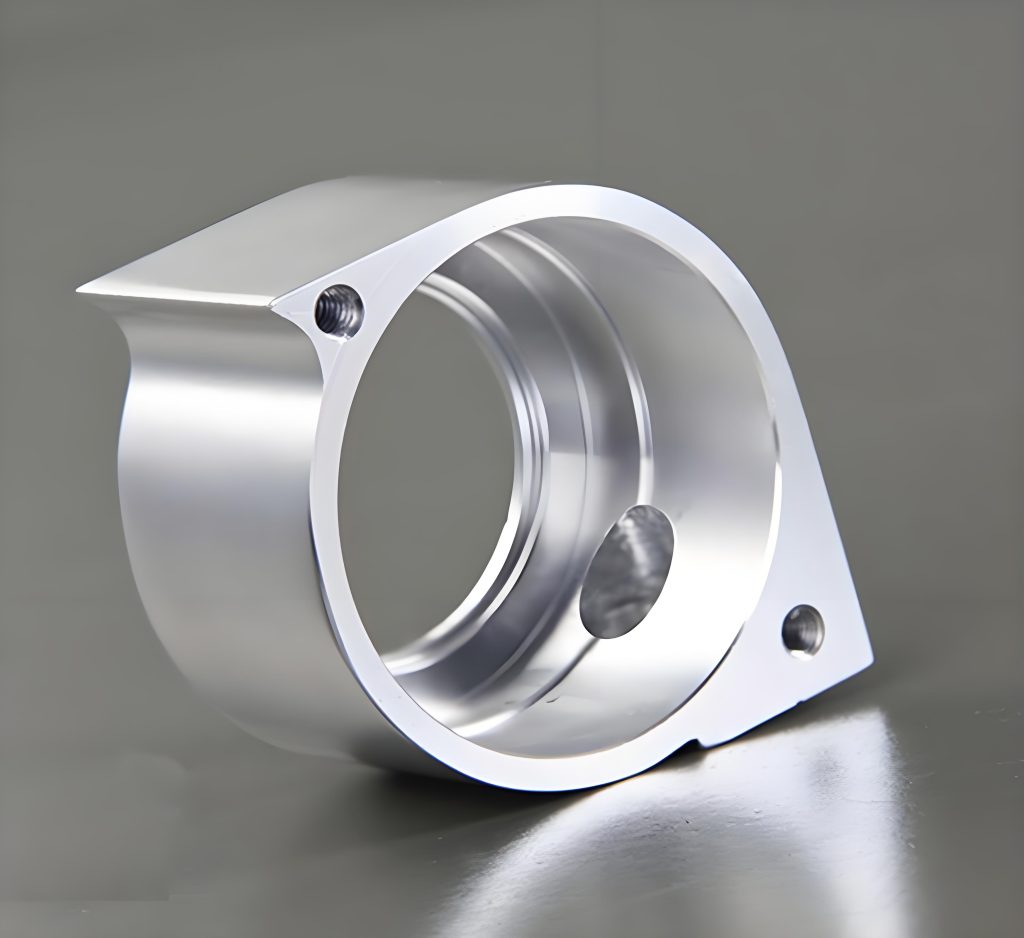

CNC machining is a highly sophisticated manufacturing process that relies on computer-controlled machinery to create precise aluminum parts. This technology has revolutionized the manufacturing industry by enabling the production of complex geometries with exceptional accuracy and repeatability.

2.1.1 Design and Programming

The process begins with the creation of a CAD (Computer-Aided Design) model. Designers use specialized software to create a three-dimensional representation of the desired aluminum part. This model contains all the necessary details such as dimensions, shapes, and features. Once the CAD model is complete, it is converted into a CAM (Computer-Aided Manufacturing) program. The CAM software takes the CAD model and generates a set of instructions, known as G codes, that tell the CNC machine how to move and cut the aluminum material.

For example, if a designer wants to create a cylindrical aluminum part with a specific diameter and length, they would use CAD software to draw the part. The CAM software would then generate G codes that instruct the CNC machine to move the cutting tool in a circular path to create the cylinder. The CAM program also takes into account factors such as tool diameter, feed rate, and spindle speed to ensure optimal cutting conditions.

2.1.2 Machining Process

Once the CAM program is generated, it is loaded into the CNC machine. The CNC machine then executes the complex operations based on the G codes. The machine uses a variety of tools such as drills, mills, and lathes to cut away excess material from the aluminum workpiece. The machine moves along multiple axes, typically three (X, Y, and Z), to create the desired shape.

For instance, in the case of a complex aluminum part with multiple curves and holes, the CNC machine will follow the G codes to move the cutting tool in a precise path. The G codes may include instructions such as moving the tool in a straight line, making a circular cut, or changing the tool’s speed and feed rate. The machine’s precision is crucial in ensuring that the final part meets the tight tolerances required by many industries.

2.1.3 Monitoring and Feedback

Real-time monitoring is an essential aspect of CNC machining for both safety and efficiency. Sensors and cameras are often used to monitor the machining process. These devices provide feedback on factors such as tool wear, cutting forces, and temperature. By continuously monitoring these parameters, operators can detect potential issues early and take corrective action to prevent damage to the machine or workpiece.

For example, if the cutting tool starts to wear out, the monitoring system can detect a change in cutting forces or surface finish. The operator can then stop the machine and replace the tool before it causes significant damage or affects the quality of the part. Real-time monitoring also allows for optimization of the machining process. By analyzing the feedback data, operators can adjust parameters such as feed rate and spindle speed to improve efficiency and quality.

In conclusion, the working principle of CNC machining involves a complex interplay of design, programming, machining, and monitoring. This technology enables the production of high-precision aluminum parts with efficiency and flexibility, making it an essential process in modern manufacturing.

2.2 Material Selection for Aluminum Parts

When it comes to CNC machining of aluminum parts, choosing the right aluminum material is crucial. Different applications require different properties, and understanding these factors can lead to better performance and durability of the final product.

2.2.1 Thermal Conductivity

Thermal conductivity is an important factor in material selection for several reasons. In applications such as electronics enclosures and heat sinks, high thermal conductivity is essential to dissipate heat effectively. Aluminum has a relatively high thermal conductivity compared to many other materials, which makes it an ideal choice for these types of applications. For example, in the electronics industry, aluminum enclosures help to keep sensitive electronic components cool, preventing overheating and ensuring proper functioning. This property also allows for faster cooling in processes where heat is generated, such as in machining itself. A material with good thermal conductivity can help to reduce the temperature of the cutting tool and workpiece, prolonging tool life and improving the quality of the finished part.

2.2.2 Strength and Corrosion Resistance

Strength and corrosion resistance are also important considerations when choosing aluminum for CNC machining. In applications where the part will be subjected to mechanical stress or exposure to harsh environments, a material with sufficient strength and corrosion resistance is essential. Different types of aluminum alloys offer varying levels of strength and corrosion resistance. For instance, some alloys are specifically designed for aerospace applications where high strength and resistance to corrosion are critical. In the aerospace industry, components must be able to withstand extreme temperatures, pressure changes, and exposure to moisture and chemicals. Aluminum alloys with enhanced strength and corrosion resistance ensure the safety and reliability of aircraft. In the automotive industry, aluminum parts for engines and transmissions need to be strong enough to handle the forces generated during operation and resistant to corrosion from exposure to oil, fuel, and other fluids. By carefully selecting the right aluminum alloy based on strength and corrosion resistance requirements, manufacturers can ensure the longevity and performance of their products.

3、Advantages of CNC Aluminum Machining

3.1 High Precision

CNC aluminum machining is renowned for its ability to achieve micron-level accuracy, making it an invaluable process in various industries. This high level of precision is made possible by the advanced technology and computer-controlled operations of CNC machines.

3.1.1 Aerospace Applications

In the aerospace industry, precision is of utmost importance. CNC aluminum machining is widely used to manufacture engine parts and fuselage structures. For example, turbine blades and compressor discs in aircraft engines require extremely tight tolerances to ensure optimal performance and safety. With CNC machining, these components can be produced with accuracy down to a few microns. This level of precision helps to reduce vibrations and improve fuel efficiency, while also enhancing the overall reliability of the aircraft. Fuselage structures also benefit from CNC aluminum machining, as it allows for the creation of complex shapes and lightweight designs that are essential for reducing weight and improving aerodynamics.

3.1.2 Medical Equipment

In the medical field, precision is crucial for the manufacture of surgical instruments and implants. CNC aluminum machining is used to create instruments such as scalpels, forceps, and retractors with exacting tolerances. These instruments need to be highly precise to ensure accurate incisions and minimal tissue damage during surgeries. Implants such as hip joints and dental implants also require micron-level accuracy to fit perfectly within the body and promote proper healing. CNC machining enables the production of these implants with consistent quality and precision, reducing the risk of complications and improving patient outcomes.

In conclusion, the high precision offered by CNC aluminum machining is a significant advantage that makes it essential in industries such as aerospace and medical equipment. The ability to achieve micron-level accuracy ensures the safety and performance of critical components, while also enabling the creation of complex designs and lightweight structures.

3.2 Consistency

CNC machining is known for its remarkable ability to ensure consistency in the production of aluminum parts. This consistency is crucial in mass production as it guarantees that each part meets the same high standards of quality and performance.

3.2.1 Automotive Manufacturing

In the automotive industry, CNC aluminum machining plays a vital role in ensuring consistency in the production of engine and body parts. For example, engine components such as cylinder heads and pistons require precise dimensions and tight tolerances to function properly. With CNC machining, these parts can be produced with consistent quality, ensuring that each engine performs at its optimal level. Body panels also benefit from CNC machining, as it allows for the creation of parts with uniform thickness and smooth surfaces. This not only enhances the aesthetic appeal of the vehicle but also improves its aerodynamics and fuel efficiency. Additionally, the consistency provided by CNC machining reduces the need for extensive quality control measures, saving time and costs in the production process.

3.2.2 Electronic Products

In the production of electronic products, consistency is essential for the proper functioning of components. CNC aluminum machining is widely used to manufacture enclosures, heat sinks, and connectors for electronic devices. These parts need to be produced with consistent dimensions and surface finishes to ensure proper fit and functionality. For instance, the connectors used in smartphones and laptops require precise tolerances to ensure a reliable connection. With CNC machining, these connectors can be produced with consistent quality, reducing the risk of connectivity issues. Heat sinks also benefit from CNC machining, as it allows for the creation of parts with uniform heat dissipation properties. This helps to keep electronic components cool and prolong their lifespan. Overall, the consistency provided by CNC aluminum machining is a significant advantage in the production of electronic products, ensuring the reliability and performance of these devices.

3.3 Automation and Flexibility

CNC aluminum machining offers significant advantages in terms of automation and flexibility. These features contribute to its popularity in various industries.

3.3.1 Small Batch Production

In small batch production, CNC aluminum machining shines. It is highly beneficial for handling diverse and small-scale orders. With traditional manufacturing methods, setting up production for small batches can be time-consuming and costly. However, CNC machines can be easily programmed to produce a wide variety of designs with minimal setup time. This makes it ideal for businesses that need to produce custom or limited-run products. For example, in the furniture industry, CNC aluminum machining can be used to create unique designs for small batches of high-end furniture pieces. The ability to quickly change designs and produce small quantities allows manufacturers to respond to market trends and customer demands more effectively. According to industry data, CNC machining can reduce production time for small batches by up to 50% compared to traditional methods.

3.3.2 Efficiency Gains

CNC aluminum machining also brings significant time and cost savings. The automation aspect reduces human intervention, minimizing the risk of human error and increasing production efficiency. Since the machines can operate continuously without the need for frequent breaks or rest, production time is greatly reduced. This leads to lower labor costs and increased output. In addition, the flexibility of CNC machines allows for optimized production processes. For instance, the same machine can be programmed to perform multiple operations, reducing the need for multiple machines and setups. This not only saves space but also reduces capital investment. Moreover, the precision and consistency offered by CNC machining reduce waste and rework, further saving costs. According to a study, companies that adopt CNC aluminum machining can achieve cost savings of up to 30% in production. Overall, the automation and flexibility of CNC aluminum machining make it a highly efficient and cost-effective manufacturing process.

4、Applications of CNC Aluminum Machining

4.1 In Aerospace

In the aerospace industry, CNC aluminum machining plays a crucial role in the manufacturing of complex parts.

4.1.1 Engine Components

Engine components in aerospace require extremely high precision. For example, turbine blades and compressor discs must have tight tolerances to ensure optimal performance and safety. These components are often subjected to high temperatures, pressures, and rotational forces, so any deviation in dimensions can lead to catastrophic failures. CNC aluminum machining can achieve accuracies within a few microns, ensuring that each part meets the strict requirements of the aerospace industry. According to industry research, about 70% of key aerospace components are made from aluminum alloys due to their lightweight and high strength properties. Materials like 7075 aluminum alloy are commonly used for engine components as they offer excellent strength-to-weight ratio and corrosion resistance.

4.1.2 Airframe Structures

Aluminum is widely used in aircraft airframe structures due to its lightweight nature. This is of utmost importance in the aerospace industry as reducing the weight of an aircraft leads to lower fuel consumption and increased payload capacity. CNC aluminum machining allows for the creation of complex shapes and designs that are essential for aerodynamic efficiency. For instance, the fuselage panels and wing spars can be manufactured with precision using CNC machines. The aerospace industry often uses advanced aluminum alloys such as 2024 aluminum alloy for airframe structures due to its high strength and good fatigue resistance. According to statistics from the aerospace sector, the use of aluminum in airframe structures can reduce the weight of an aircraft by up to 30% compared to traditional materials. Moreover, CNC machining enables the integration of various features and attachments directly into the aluminum parts, reducing the need for additional assembly steps and improving the overall structural integrity of the aircraft.

4.2 In Automotive

The automotive industry has also greatly benefited from CNC aluminum machining.

4.2.1 Body Structures

In modern car manufacturing, lightweight and durable aluminum parts play a crucial role. The use of aluminum in body structures offers several advantages. Firstly, it reduces the overall weight of the vehicle, which leads to improved fuel efficiency. According to industry data, every 10% reduction in vehicle weight can result in a 6% to 8% improvement in fuel economy. CNC aluminum machining enables the production of complex body panels and structural components with high precision. For example, the hood, doors, and fenders can be manufactured with exacting tolerances to ensure a perfect fit and seamless appearance. Aluminum alloys such as 6061 and 5052 are commonly used in automotive body structures due to their excellent strength-to-weight ratio and corrosion resistance. These alloys can be machined to create parts that are not only lightweight but also durable enough to withstand the rigors of daily use and various environmental conditions. Additionally, CNC machining allows for the integration of design features such as aerodynamic shapes and strengthening ribs, enhancing the overall performance and safety of the vehicle.

4.2.2 Interior Components

CNC aluminum machining also plays a significant role in enhancing the aesthetics and functionality of automotive interior components. Aluminum trim pieces, such as dashboard panels, door handles, and gear shifters, can add a touch of luxury and sophistication to the vehicle’s interior. The precision offered by CNC machining ensures that these components have a smooth finish and tight tolerances, giving them a high-quality look and feel. Moreover, aluminum interior components can be designed to be both functional and stylish. For instance, aluminum ventilation grilles can be machined to provide optimal air flow while also adding a decorative element to the interior. In addition, CNC machining allows for the integration of features such as backlighting and logos, further enhancing the visual appeal of the interior. Furthermore, aluminum is a durable material that can withstand the wear and tear of daily use, making it an ideal choice for interior components. According to market research, the use of aluminum in automotive interiors is on the rise as consumers demand more luxurious and high-quality interiors.

5、Future Trends

5.1 Integration of Technologies

As technology continues to advance, the future of CNC aluminum machining is set to be shaped by the integration of artificial intelligence (AI) and the Internet of Things (IoT). This integration holds great promise for enhancing the efficiency, precision, and overall performance of the machining process.

5.1.1 Intelligent Systems

The incorporation of AI in CNC aluminum machining is expected to bring about significant changes. Intelligent systems will have the ability to learn from past machining operations and optimize processes for better results. For example, AI algorithms can analyze data from previous jobs to determine the optimal cutting parameters, tool paths, and machining strategies. This self-learning capability can lead to improved productivity and reduced waste. In addition, intelligent systems can detect potential issues before they occur and take preventive measures. For instance, if an AI system detects signs of tool wear or abnormal vibrations, it can alert the operator or even adjust the machining parameters in real-time to prevent damage to the workpiece or machine. According to industry experts, the use of AI in CNC machining could increase productivity by up to 30% and reduce production costs by up to 20%.

5.1.2 Remote Monitoring

The integration of IoT in CNC aluminum machining enables efficient remote monitoring and management of the machining process. Sensors and connected devices can be used to collect real-time data on machine performance, tool wear, and workpiece quality. This data can be transmitted to a central monitoring system, allowing operators and managers to monitor the process from anywhere in the world. For example, if a problem occurs during machining, an alert can be sent to the operator’s mobile device, enabling them to take immediate action. Remote monitoring also allows for predictive maintenance, as data on machine health can be analyzed to predict when maintenance is needed. This can help to reduce downtime and increase the availability of the machining equipment. According to a recent study, the implementation of IoT in manufacturing can lead to a reduction in downtime by up to 50% and an increase in equipment efficiency by up to 25%.

In conclusion, the integration of AI and IoT in CNC aluminum machining represents a major step forward in the evolution of this important manufacturing process. These technologies have the potential to improve efficiency, precision, and quality, while also reducing costs and downtime. As the manufacturing industry continues to embrace digital transformation, the future of CNC aluminum machining looks bright.

5.2 New Materials and Green Manufacturing

As the field of CNC aluminum machining continues to evolve, the adaptation to new materials and the adoption of sustainable practices are becoming increasingly important.

5.2.1 Adaptation to New Materials

The future of CNC aluminum machining lies in its ability to adapt to new materials. With the continuous development of material science, new alloys and composite materials are emerging that offer unique properties and advantages. For example, advanced aluminum alloys with enhanced strength, corrosion resistance, and thermal conductivity are being developed. These materials can expand the application range of CNC aluminum machining and enable the production of parts with even better performance.

In addition to new aluminum alloys, composite materials that combine aluminum with other materials such as carbon fiber or ceramics are also gaining attention. These composites offer a combination of high strength, lightweight, and excellent thermal properties. CNC machining can be used to shape and finish these composite materials, opening up new possibilities for applications in industries such as aerospace and automotive.

The adaptation to new materials requires continuous research and development in machining techniques and tooling. CNC machine manufacturers and tool suppliers are working on developing new cutting tools and machining processes that can handle these advanced materials. This includes optimizing cutting parameters, developing specialized tool coatings, and exploring new machining strategies to ensure efficient and accurate processing.

5.2.2 Sustainable Practices

Sustainable manufacturing is a growing trend in the industry, and CNC aluminum machining is no exception. Green manufacturing practices can help reduce energy consumption, minimize waste, and lower the environmental impact of the machining process.

One aspect of sustainable practices is energy savings. CNC machines consume a significant amount of energy, especially during high-speed machining operations. Manufacturers are exploring ways to optimize machine settings and processes to reduce energy consumption. This can include using energy-efficient motors, implementing intelligent power management systems, and optimizing cutting speeds and feeds to minimize power consumption.

Another important aspect is waste reduction. In CNC machining, waste is generated in the form of chips, coolant, and worn-out tools. To reduce waste, manufacturers are implementing recycling and reuse programs. For example, chips can be recycled and reused as raw material for new aluminum parts. Coolant can be filtered and reused, reducing the need for fresh coolant. Worn-out tools can be refurbished or recycled, reducing the amount of waste sent to landfills.

In addition to energy savings and waste reduction, sustainable manufacturing also involves the use of environmentally friendly materials and processes. For example, water-based coolants are being developed as an alternative to traditional oil-based coolants. These water-based coolants are less harmful to the environment and can be disposed of more easily. Manufacturers are also exploring the use of biodegradable materials and processes to further reduce the environmental impact of CNC aluminum machining.

In conclusion, the future of CNC aluminum machining will be shaped by the adaptation to new materials and the adoption of sustainable practices. By expanding the application range through the use of new materials and implementing green manufacturing practices, the industry can continue to grow and contribute to a more sustainable future.

6、Conclusion

6.1 Summary of Findings

CNC aluminum machining offers a multitude of advantages and has extensive applications across various industries. The high precision achievable with CNC machines is crucial in industries like aerospace and medical equipment, where even the slightest deviation can have significant consequences. The consistency provided by CNC machining ensures that each part meets the same high standards, making it ideal for mass production in industries such as automotive and electronics. The automation and flexibility of CNC aluminum machining enable efficient production, whether it’s for small batch production or large-scale manufacturing.

In the aerospace industry, CNC aluminum machining is used to manufacture engine components and airframe structures. The ability to achieve tight tolerances and create complex shapes is essential for the safety and performance of aircraft. In the automotive industry, lightweight aluminum parts produced by CNC machining contribute to improved fuel efficiency and enhanced vehicle performance. The use of CNC aluminum machining in interior components also adds to the aesthetics and functionality of vehicles.

6.2 Implications for Industry

The widespread use of CNC aluminum machining has significant implications for the manufacturing industry. As technology continues to advance, the integration of AI and IoT in CNC machining will further enhance efficiency and precision. The adaptation to new materials will expand the application range of CNC aluminum machining, while sustainable practices will help reduce the environmental impact.

Manufacturers need to stay updated with the latest technological advancements and invest in advanced CNC machines and tooling. Training and upskilling of employees will also be crucial to ensure they can operate and maintain these sophisticated machines. Additionally, collaboration between different stakeholders in the supply chain, including machine manufacturers, tool suppliers, and end-users, will be essential for driving innovation and growth in the CNC aluminum machining industry.

6.3 Future Research Directions

Future research in CNC aluminum machining could focus on several areas. One area is the further development of intelligent machining systems that can optimize processes in real-time and adapt to changing conditions. Another area is the exploration of new materials and composites that offer enhanced properties and can be processed efficiently by CNC machines. Research on sustainable manufacturing practices, such as energy-efficient machining and waste reduction, will also be important.

In conclusion, CNC aluminum machining is a vital manufacturing process that offers significant benefits and has a bright future. Continued research and innovation will ensure that it remains at the forefront of modern manufacturing, contributing to the growth and development of various industries.

6.2 Outlook for the Future

Looking ahead, the field of CNC aluminum machining is poised for significant growth and evolution. As technology continues to advance at a rapid pace, several trends are likely to shape the future of this important manufacturing process.

One of the key areas of development will be the further integration of advanced technologies such as artificial intelligence (AI) and the Internet of Things (IoT). As discussed earlier, these technologies have the potential to enhance efficiency, precision, and overall performance. Intelligent systems powered by AI will become more sophisticated, able to optimize machining processes in real-time based on a vast amount of data. This will lead to even greater productivity gains and reduced waste. IoT-enabled remote monitoring will also become more widespread, allowing for seamless management of machining operations from anywhere in the world.

The adaptation to new materials will also play a crucial role in the future of CNC aluminum machining. As new alloys and composite materials emerge, CNC machines will need to be adapted to handle these materials effectively. This will require continuous research and development in machining techniques and tooling. Manufacturers will need to invest in advanced cutting tools and machining processes that can handle the unique properties of these new materials. For example, materials with enhanced strength, corrosion resistance, and thermal conductivity will open up new applications in industries such as aerospace and automotive.

Sustainable manufacturing practices will continue to gain importance. As the world becomes more environmentally conscious, the demand for green manufacturing solutions will increase. CNC aluminum machining will need to adopt energy-efficient processes, reduce waste, and use environmentally friendly materials. This will not only help to reduce the environmental impact but also improve the competitiveness of manufacturers. For instance, the use of water-based coolants and biodegradable materials will become more common.

In addition, the demand for customized and complex parts will drive the need for more flexible and versatile CNC machines. Small batch production will become more prevalent, and manufacturers will need to be able to quickly adapt to changing customer demands. This will require machines that can be easily programmed and reconfigured to produce a wide variety of designs.

The future of CNC aluminum machining also holds great promise for collaboration and innovation. As different stakeholders in the supply chain work together, new ideas and solutions will emerge. For example, machine manufacturers, tool suppliers, and end-users can collaborate to develop advanced machining processes and materials. This collaborative approach will help to drive the growth and evolution of the industry.

In conclusion, the future of CNC aluminum machining is bright. With the continuous integration of advanced technologies, adaptation to new materials, and adoption of sustainable practices, this manufacturing process will continue to play a vital role in various industries. The demand for high-precision, customized, and sustainable parts will drive innovation and growth, ensuring that CNC aluminum machining remains at the forefront of modern manufacturing.

Recommend rapidefficient CNC aluminum processing service provider

When it comes to finding a reliable and efficient CNC aluminum processing service provider, several factors should be considered. One of the key aspects is the provider’s expertise in handling different types of aluminum alloys and complex designs.

A good service provider should have state-of-the-art CNC machines and advanced software for design and programming. For example, companies like JMA Aluminium are leaders in the aluminum processing industry. They have been manufacturing aluminum profiles since 1993 and have an annual output of 300,000 tons of aluminum profiles. Their design team consists of 70 people divided into die design and product design departments, ensuring high-quality and innovative designs.

Another important factor is the provider’s ability to offer rapid processing. Rapid processing is crucial in industries where time-to-market is essential. Service providers that can offer quick turnaround times without sacrificing quality are highly sought after. For instance, some providers use synchronous processing for events that require minimal and rapid processing. High chloride emulsions are particularly suitable for preparing photographic materials for rapid processing, and this concept can be applied to CNC aluminum processing as well.

In addition to speed, quality control is essential. A reliable service provider should have a dedicated quality control department to ensure that each part meets the strictest standards. This includes checking for dimensional accuracy, surface finish, and material properties. For example, JMA Aluminium attaches great importance to the quality of their aluminum products and has a testing team of more than 200 people divided into quality inspection and quality assurance departments.

Moreover, a good service provider should offer flexibility in production. They should be able to handle small batch production as well as large-scale orders. This flexibility is important for businesses that need to respond quickly to market changes or have unique customization requirements. For example, in the furniture industry, CNC aluminum machining can be used to create unique designs for small batches of high-end furniture pieces. Service providers that can handle such diverse orders are more likely to meet the needs of different customers.

Finally, customer service is also a crucial factor. A good service provider should have a responsive customer service team that can answer queries promptly and provide updates on the production process. They should also be able to work closely with customers to understand their specific requirements and offer solutions that meet their needs.

In conclusion, when looking for a rapidefficient CNC aluminum processing service provider, it is important to consider factors such as expertise, speed, quality control, flexibility, and customer service. By choosing the right service provider, businesses can ensure high-quality products, timely delivery, and cost-effective solutions.