1、Introduction

Rapidefficient is at the forefront of providing top-notch CNC machining services for automotive components. In this article, we will explore the world of CNC turning for automotive parts and highlight the unique features and benefits of choosing Rapidefficient as your trusted machining partner.

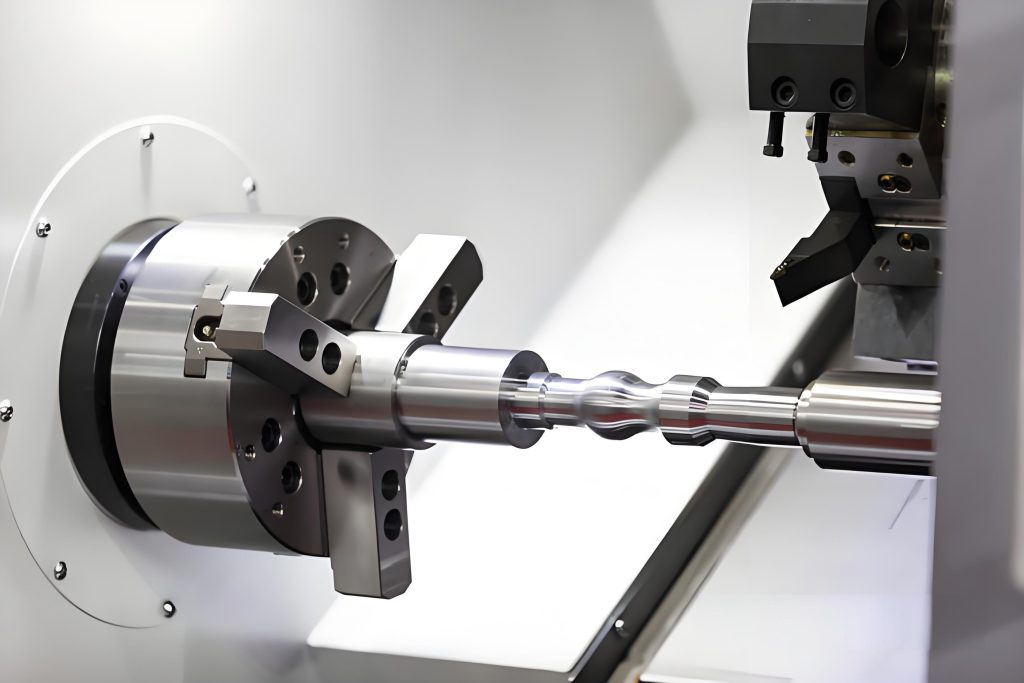

CNC turning for automotive components is a crucial process in the automotive industry. It involves the use of computer-controlled machines to shape and finish various parts of a vehicle. Let’s start by understanding what CNC turning is.

Cnc is short for Computerized Numerical Control. It refers to the process of using computers to control machines for tasks such as cutting, drilling, and milling. In the context of automotive components, CNC turning is used to create precise and complex shapes with high accuracy and repeatability.

The term ‘turning’ comes from the action of rotating a workpiece while a cutting tool is applied to remove material and shape the part. As defined in the sources, turning is “the process of rotating a workpiece while a cutting tool is applied to remove material and shape the part. It is used in various industries, including automotive, for creating cylindrical or conical shapes.”

Automotive components require high precision and quality, as they play a critical role in the performance and safety of a vehicle. CNC turning offers several advantages for manufacturing these components.

One of the key benefits of CNC turning for automotive parts is the ability to produce complex shapes with tight tolerances. This is essential for ensuring proper fit and function of components such as engine parts, transmission components, and suspension parts. With CNC turning, manufacturers can achieve extremely accurate dimensions and surface finishes, reducing the need for additional machining or finishing processes.

Another advantage is the high level of automation offered by CNC machines. This allows for consistent quality and increased production efficiency. Automated processes can reduce human error and ensure that each part is produced to the same specifications. Additionally, CNC machines can operate continuously, reducing production time and increasing output.

In the automotive industry, different materials are used for various components. CNC turning can handle a wide range of materials, including metals such as steel, aluminum, and titanium, as well as plastics and composites. This versatility makes it possible to produce a diverse range of automotive parts to meet the specific requirements of different applications.

For example, aluminum is a popular material for automotive components due to its lightweight and corrosion-resistant properties. According to the sources, “6061 Aluminum is one of the most widely used aluminum alloys for CNC machining. It offers good strength, excellent machinability, and weldability. Aluminum 6061-T6 Machined Parts is commonly used for a wide range of applications, including machine parts, automotive components, and structural components.”

Similarly, 7075 aluminum is known for its high strength-to-weight ratio and is often used in aerospace and military applications. In the automotive industry, it can be used for high-stress components such as engine parts and suspension components. However, machining 7075 aluminum requires specialized tooling and cutting parameters due to its hardness.

In addition to aluminum, steel is also commonly used for automotive components. Different grades of steel offer varying levels of strength, hardness, and corrosion resistance. CNC turning can handle different types of steel, allowing manufacturers to choose the most suitable material for a particular application.

The process of CNC turning for automotive components typically involves several steps. First, the design of the part is created using computer-aided design (CAD) software. This design is then converted into a set of instructions for the CNC machine using computer-aided manufacturing (CAM) software.

The CNC machine then follows these instructions to shape the workpiece. The cutting tool is moved along different axes to remove material and create the desired shape. The machine can perform operations such as turning, milling, drilling, and threading to achieve the final product.

During the machining process, quality control is essential to ensure that the parts meet the required specifications. This may involve inspecting the dimensions, surface finish, and material properties of the parts. Advanced inspection techniques such as coordinate measuring machines (CMMs) and optical scanners can be used to ensure accurate measurements and detect any defects.

Rapidefficient offers a comprehensive range of CNC turning services for automotive components. Our state-of-the-art facilities are equipped with the latest CNC machines and technology to ensure high-quality and efficient production.

Our team of experienced machinists and engineers has extensive knowledge and expertise in CNC turning for automotive applications. We can handle projects of all sizes and complexities, from small batch production to large-scale volume production.

At Rapidefficient, we understand the importance of quality and reliability in the automotive industry. That’s why we have implemented strict quality control measures throughout our production process. We use advanced inspection equipment and techniques to ensure that each part meets the highest standards of quality.

In addition to CNC turning, we also offer other machining services such as milling, drilling, and grinding. This allows us to provide a one-stop solution for all your automotive machining needs.

Our commitment to customer satisfaction is reflected in our excellent service and support. We work closely with our customers to understand their specific requirements and provide customized solutions that meet their needs. From design and prototyping to production and delivery, we are dedicated to providing a seamless experience for our customers.

In conclusion, CNC turning for automotive components is a critical process that offers many advantages for the automotive industry. Rapidefficient is a trusted provider of CNC machining services for automotive components, offering high-quality, efficient, and reliable solutions. Whether you need small batch production or large-scale volume production, we have the expertise and resources to meet your needs. Contact us today to learn more about our CNC turning services and how we can help you with your automotive machining projects.

2、What is CNC Turning for Automotive Components?

CNC turning for automotive components is a highly specialized and crucial manufacturing process within the automotive industry. It involves the use of computer-controlled machines to precisely shape and cut various parts that are essential for the proper functioning and performance of vehicles.

The process of CNC turning is based on computer numerical control (CNC), which is a technology that allows for the automated control of machine tools. As defined by various sources, CNC is the abbreviation for Computerized Numerical Control. It enables the precise control of cutting tools to remove material from a workpiece and create complex shapes with high accuracy.

In the context of automotive components, turning refers to the act of rotating a workpiece while a cutting tool is applied to shape it. This process is essential for creating cylindrical or conical shapes that are commonly found in automotive parts such as engine shafts, transmission components, and suspension parts.

Automotive components require a high degree of precision and quality, as they play a critical role in the safety and performance of vehicles. CNC turning offers several advantages in meeting these requirements. One of the key benefits is the ability to produce complex shapes with tight tolerances. This ensures that the parts fit together properly and function as intended.

For example, in engine components, precise dimensions and surface finishes are essential for proper lubrication and reduced friction. CNC turning can achieve extremely accurate dimensions and smooth surfaces, minimizing the risk of engine failure and improving fuel efficiency.

Another advantage of CNC turning for automotive components is the high level of automation it offers. This reduces human error and ensures consistent quality across all parts. Automated processes can also increase production efficiency, allowing manufacturers to meet the high demand for automotive parts.

CNC machines can handle a wide range of materials commonly used in the automotive industry. Metals such as steel, aluminum, and titanium are frequently processed using CNC turning. Plastics and composites are also used in some applications.

Aluminum, for instance, is popular due to its lightweight and corrosion-resistant properties. According to industry sources, 6061 Aluminum is widely used for CNC machining in the automotive industry. It offers good strength, excellent machinability, and weldability. Aluminum 6061-T6 Machined Parts are commonly found in various automotive applications, including machine parts, structural components, and body panels.

Steel is another important material for automotive components. Different grades of steel offer varying levels of strength, hardness, and corrosion resistance. CNC turning can process different types of steel to meet the specific requirements of different parts.

The process of CNC turning for automotive components typically involves several steps. First, the design of the part is created using computer-aided design (CAD) software. This design is then converted into a set of instructions for the CNC machine using computer-aided manufacturing (CAM) software.

The CNC machine follows these instructions to shape the workpiece. The cutting tool is moved along different axes to remove material and create the desired shape. Operations such as turning, milling, drilling, and threading can be performed to achieve the final product.

During the machining process, quality control is essential to ensure that the parts meet the required specifications. Advanced inspection techniques such as coordinate measuring machines (CMMs) and optical scanners are used to measure dimensions and detect any defects.

Rapidefficient is a leading provider of CNC turning services for automotive components. Our state-of-the-art facilities are equipped with the latest CNC machines and technology to ensure high-quality and efficient production.

Our team of experienced machinists and engineers has extensive knowledge and expertise in CNC turning for automotive applications. We can handle projects of all sizes and complexities, from small batch production to large-scale volume production.

At Rapidefficient, we understand the importance of quality and reliability in the automotive industry. That’s why we have implemented strict quality control measures throughout our production process. We use advanced inspection equipment and techniques to ensure that each part meets the highest standards of quality.

In addition to CNC turning, we also offer other machining services such as milling, drilling, and grinding. This allows us to provide a one-stop solution for all your automotive machining needs.

Our commitment to customer satisfaction is reflected in our excellent service and support. We work closely with our customers to understand their specific requirements and provide customized solutions that meet their needs. From design and prototyping to production and delivery, we are dedicated to providing a seamless experience for our customers.

In conclusion, CNC turning for automotive components is a critical process that offers many advantages for the automotive industry. Rapidefficient is a trusted provider of CNC machining services for automotive components, offering high-quality, efficient, and reliable solutions. Whether you need small batch production or large-scale volume production, we have the expertise and resources to meet your needs. Contact us today to learn more about our CNC turning services and how we can help you with your automotive machining projects.

2、Benefits of CNC Turning for Automotive Components

2.1 High precision and accuracy

CNC turning is renowned for ensuring that automotive components are manufactured with extremely tight tolerances. This level of precision results in a superior fit and enhanced performance. The process allows for the creation of components with dimensions that are accurate to within a very small margin of error. For example, parts like engine pistons and transmission gears require a high degree of precision to function properly. With CNC turning, these components can be produced with such accuracy that they fit together seamlessly, reducing friction and increasing the efficiency of the vehicle’s systems.

This precision also extends to surface finishes. The cutting tools used in CNC turning can create smooth surfaces that minimize resistance and wear. In automotive applications, this is crucial for components that are subject to high levels of stress and friction, such as bearings and shafts. By achieving a high level of precision and accuracy, CNC turning helps to ensure the longevity and reliability of automotive components.

2.2 Increased production efficiency

Automated processes and advanced technology play a significant role in enabling faster production times in CNC turning for automotive components. This is essential in the fast-paced environment of the automotive industry, where demand for parts is often high and time is of the essence.

The use of computer-controlled machines in CNC turning allows for consistent and repeatable operations. Once a program is set up, the machine can run continuously without the need for constant human intervention. This reduces the risk of human error and ensures that each part is produced to the same specifications. Automated processes also enable the simultaneous machining of multiple parts, further increasing production efficiency.

In addition, CNC turning can optimize tool paths and cutting parameters to minimize waste and maximize material removal rates. This not only saves time but also reduces material costs. The ability to quickly change setups and switch between different part designs also contributes to increased production efficiency. Overall, CNC turning offers a highly efficient solution for meeting the demands of the automotive industry.

2.3 Versatility

CNC turning is highly versatile and can produce a wide variety of automotive components. From small intricate parts such as sensors and connectors to large structural components like engine blocks and chassis parts, CNC turning can handle it all.

The term ‘versatility’ refers to the ability to adapt to different tasks and requirements. In the context of CNC turning for automotive components, this means that the same machine can be used to produce different types of parts with different shapes, sizes, and materials. According to the sources, versatility is one of the key characteristics of CNC turning.

For example, CNC turning can handle a wide range of materials commonly used in the automotive industry, including metals such as steel, aluminum, and titanium, as well as plastics and composites. This allows manufacturers to choose the most suitable material for a particular application based on factors such as strength, weight, and cost.

In addition to material versatility, CNC turning also offers flexibility in design. Complex shapes and geometries can be easily achieved using computer-aided design and manufacturing software. This enables designers to create innovative and optimized components that meet the specific requirements of different vehicle models and applications.

Overall, the versatility of CNC turning makes it an ideal choice for the automotive industry, where a diverse range of components is needed to meet the ever-evolving demands of vehicle design and performance.

In conclusion, CNC turning for automotive components offers numerous benefits, including high precision and accuracy, increased production efficiency, and versatility. Rapidefficient is a leading provider of CNC turning services for the automotive industry, offering state-of-the-art facilities and a team of experienced professionals. Whether you need small batch production or large-scale volume production, Rapidefficient has the expertise and resources to meet your needs. Contact us today to learn more about our CNC turning services and how we can help you with your automotive machining projects.

3、Rapidefficient’s CNC Machining Services for Automotive

3.1 State-of-the-art equipment

Rapidefficient is equipped with the latest CNC machines and technology, ensuring high-quality and efficient production. Our advanced equipment allows us to handle a wide variety of automotive components with precision and speed. Whether it’s complex geometries or tight tolerances, our state-of-the-art machines are up to the task. With features like multi-axis capabilities and high-speed cutting, we can produce parts that meet the exacting standards of the automotive industry.

3.2 Skilled workforce

Our team of experienced machinists and engineers is dedicated to providing exceptional service and quality. Skilled workers are the backbone of our operation. At Rapidefficient, our machinists are highly trained and have extensive experience in CNC machining for automotive applications. They are proficient in using the latest technology and techniques to ensure that each part is produced to the highest standards. Our engineers, on the other hand, are experts in design and process optimization. They work closely with our customers to understand their specific requirements and develop customized solutions that meet their needs.

3.3 Custom solutions

We offer customized CNC machining services to meet the unique needs of each customer. At Rapidefficient, we understand that every automotive project is different. That’s why we offer custom solutions to meet the unique needs of each customer. Whether it’s a one-off prototype or a large-scale production run, we can develop a solution that fits your requirements. Our team of experts will work with you from design to delivery to ensure that your parts are produced exactly as you need them. We can handle a wide range of materials and part sizes, and our advanced software and technology allow us to create complex geometries and tight tolerances. With Rapidefficient, you can be confident that you’re getting a custom solution that meets your specific needs.

4、Why Choose Rapidefficient?

4.1 Quality and reliability

Rapidefficient is committed to providing high-quality products and services. Our strict quality control processes ensure that every part meets or exceeds industry standards. We take pride in our attention to detail and our dedication to delivering only the best. With Rapidefficient, you can be confident that your automotive components will be of the highest quality.

4.2 Competitive pricing

We offer competitive pricing without sacrificing quality, making us a cost-effective choice for your automotive machining needs. Our efficient production processes and economies of scale allow us to pass on savings to our customers. At Rapidefficient, you get the best of both worlds – high-quality products and affordable prices.

4.3 Fast turnaround times

Our efficient production processes and dedicated team enable us to deliver your parts on time, every time. We understand the importance of meeting deadlines in the automotive industry, and we go the extra mile to ensure that your orders are fulfilled promptly. With Rapidefficient, you can count on fast turnaround times and reliable service.

5、Conclusion

In conclusion, Rapidefficient is your go-to source for high-quality CNC machining services for automotive components. With our state-of-the-art equipment, skilled workforce, and commitment to quality and service, we are confident that we can meet your machining needs and exceed your expectations. Choose Rapidefficient for all your automotive machining requirements.

Rapidefficient offers a comprehensive range of CNC turning services for automotive components. Our advanced facilities are equipped with the latest CNC machines and technology, ensuring high-quality and efficient production. Our team of experienced machinists and engineers has extensive knowledge and expertise in CNC turning for automotive applications.

The state-of-the-art equipment at Rapidefficient allows us to handle a wide variety of automotive components with precision and speed. Whether it’s complex geometries or tight tolerances, our machines are up to the task. With features like multi-axis capabilities and high-speed cutting, we can produce parts that meet the exacting standards of the automotive industry.

Our skilled workforce is the backbone of our operation. Our machinists are highly trained and have extensive experience in CNC machining for automotive applications. They are proficient in using the latest technology and techniques to ensure that each part is produced to the highest standards. Our engineers are experts in design and process optimization. They work closely with our customers to understand their specific requirements and develop customized solutions that meet their needs.

At Rapidefficient, we understand the importance of quality and reliability in the automotive industry. That’s why we have implemented strict quality control measures throughout our production process. We use advanced inspection equipment and techniques to ensure that each part meets the highest standards of quality.

In addition to CNC turning, we also offer other machining services such as milling, drilling, and grinding. This allows us to provide a one-stop solution for all your automotive machining needs.

Our commitment to customer satisfaction is reflected in our excellent service and support. We work closely with our customers to understand their specific requirements and provide customized solutions that meet their needs. From design and prototyping to production and delivery, we are dedicated to providing a seamless experience for our customers.

So, if you’re looking for a reliable and high-quality CNC machining service for automotive components, look no further than Rapidefficient. Contact us today to learn more about our services and how we can help you with your automotive machining projects.