1、Introduction

Precision custom CNC machining is a crucial process in various industries, providing highly accurate and tailored solutions for diverse needs. This article will explore the world of precision CNC machining services and custom CNC machining, highlighting their benefits and how to choose the right service provider.

In today’s industrial landscape, precision is of utmost importance. Whether it’s in the aerospace, automotive, electronics, or any other high-tech industry, the demand for accurate and precisely manufactured components is ever-increasing. This is where precision custom CNC machining comes into play.

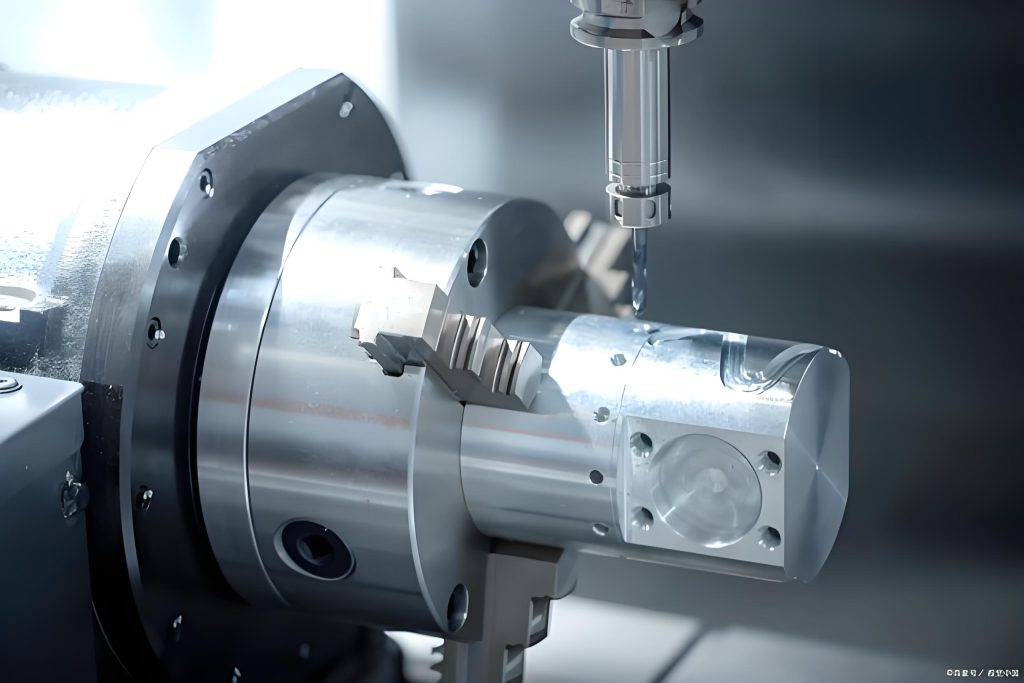

CNC machining, which stands for Computer Numerical Control machining, is a manufacturing process that uses computer-controlled machines to cut and shape materials with extreme precision. It offers several advantages over traditional machining methods.

One of the key benefits of precision custom CNC machining is its ability to produce complex and intricate parts with high accuracy. The computer-controlled machines can follow detailed instructions and cut materials with micrometer-level precision, ensuring that each part meets the exact specifications required. This is especially important in industries where even the slightest deviation can lead to performance issues or safety hazards.

Another advantage is the flexibility it offers. With CNC machining, it is possible to produce a wide variety of parts in different shapes, sizes, and materials. Whether you need a small batch of prototypes or large-scale production runs, CNC machining can be customized to meet your specific needs.

Moreover, precision custom CNC machining can significantly reduce production time and costs. The automated nature of the process allows for faster production speeds and less waste of materials. Additionally, once the program is set up, the machines can run continuously without the need for constant supervision, further increasing efficiency.

When it comes to choosing a precision CNC machining service provider, there are several factors to consider. First and foremost, look for a company with extensive experience and expertise in the field. A provider that has been in business for a long time and has a proven track record of delivering high-quality parts is more likely to meet your expectations.

Check the company’s capabilities and equipment. Make sure they have the latest CNC machines and technologies to ensure accurate and efficient production. Also, inquire about their quality control processes to ensure that your parts will be manufactured to the highest standards.

Customer service is also an important aspect. A good service provider should be responsive to your inquiries, provide timely updates on your orders, and be willing to work with you to address any concerns or issues that may arise.

In conclusion, precision custom CNC machining is a vital process in today’s industrial world. It offers numerous benefits, including high accuracy, flexibility, and cost-effectiveness. By choosing the right service provider, you can ensure that your components are manufactured to the highest quality standards and meet your specific needs.

2、What is Precision CNC Machining?

2.1 Definition and Process

Precision CNC machining is a highly advanced manufacturing process that combines computer technology with mechanical engineering. Computer Numerical Control (CNC) machining is a method where a computer controls the movement of cutting tools to remove excess material from a workpiece. This process is capable of achieving extremely high levels of accuracy and quality, making it ideal for creating parts with complex geometries.

In precision CNC machining, the computer program is carefully designed to ensure that the cutting tools follow a precise path. The program takes into account factors such as the shape and size of the workpiece, the type of material being used, and the desired final product. The cutting tools are then guided by the computer to remove material in a controlled manner, resulting in a part that meets the exact specifications required.

The level of accuracy achieved in precision CNC machining is truly remarkable. With micrometer-level precision, even the smallest details can be accurately reproduced. This makes it possible to create parts that are not only highly functional but also aesthetically pleasing.

2.2 Types of Precision CNC Machining Services

- CNC milling: This is a versatile machining process that can handle a wide range of part geometries. Capable of 3, 4, and 5-axis machining, it can create both simple and complex parts. In 3-axis milling, the workpiece remains stationary while the cutting tool moves in the XYZ plane. This is a widely used method for creating parts with flat surfaces and basic shapes. For more complex geometries, 4-axis and 5-axis milling can be used. In 4-axis milling, the workpiece can be rotated around one axis, allowing for the creation of parts with curved surfaces and undercuts. In 5-axis milling, the workpiece can be rotated and tilted in multiple directions, enabling the creation of highly complex parts with intricate shapes.

- CNC turning: Ideal for cylindrical parts, CNC turning uses a lathe to rotate the workpiece while a cutting tool removes material. This process can handle both standard and power accessory functions, allowing for the creation of a wide variety of cylindrical parts. With high precision and repeatability, CNC turning is widely used in industries such as automotive, aerospace, and medical.

- 3 Axis Machining: As mentioned earlier, 3-axis machining is a common method where the workpiece remains stationary and cutting tools operate in the XYZ plane. This is a cost-effective way to create parts with relatively simple geometries. However, it may require manual repositioning of the workpiece for more complex shapes, which can increase production time. Despite this limitation, 3-axis machining is still widely used due to its simplicity and reliability.

3、What is Custom CNC Machining?

3.1 Understanding Customization

Custom CNC machining is a highly specialized manufacturing process that offers the ability to create unique parts tailored to specific requirements. It goes beyond traditional machining methods by leveraging computer-controlled machines that follow precise programming instructions. This allows for a level of customization that is essential in today’s diverse industrial landscape.

Each project in custom CNC machining is unique, and the programming of the CNC machines is carefully crafted to meet the specific needs of that particular project. The process involves a deep understanding of the materials being used, the desired shape and dimensions of the part, and the functionality required. By programming the machines with these specific instructions, manufacturers can ensure that every part produced is exactly as intended.

3.2 Capabilities and Materials

- Capabilities include CNC turning, milling, and manufacturing with advanced 3D printers and reliable technologies.

- CNC turning is ideal for cylindrical parts. It uses a lathe to rotate the workpiece while a cutting tool removes material. This process can handle both standard and power accessory functions, allowing for the creation of a wide variety of cylindrical parts. With high precision and repeatability, CNC turning is widely used in industries such as automotive, aerospace, and medical.

- CNC milling is a versatile machining process that can handle a wide range of part geometries. Capable of 3, 4, and 5-axis machining, it can create both simple and complex parts. In 3-axis milling, the workpiece remains stationary while the cutting tool moves in the XYZ plane. This is a widely used method for creating parts with flat surfaces and basic shapes. For more complex geometries, 4-axis and 5-axis milling can be used. In 4-axis milling, the workpiece can be rotated around one axis, allowing for the creation of parts with curved surfaces and undercuts. In 5-axis milling, the workpiece can be rotated and tilted in multiple directions, enabling the creation of highly complex parts with intricate shapes.

- Advanced 3D printers are also used in custom CNC machining. They offer the ability to create complex geometries that may be difficult or impossible to achieve with traditional machining methods. These printers use a variety of materials and can produce parts with high precision and detail.

- Materials range from metals like aluminum, steel, brass, and titanium to plastics and ceramics.

- Metals such as aluminum, steel, brass, and titanium are commonly used in custom CNC machining due to their strength, durability, and machinability. These materials can be used to create parts for a wide range of applications, from aerospace components to medical devices.

- Plastics are also a popular choice for custom CNC machining. They offer a variety of properties such as flexibility, lightweight, and resistance to chemicals. Plastics can be used to create parts for consumer products, electronics, and industrial equipment.

- Ceramics are used in custom CNC machining for applications that require high temperature resistance, wear resistance, and electrical insulation. Ceramics can be machined into complex shapes and used in industries such as aerospace, electronics, and medical.

4、Benefits of Custom CNC Machining

4.1 High Precision and Accuracy

Custom CNC machining offers extremely high precision and accuracy. Parts are made to exact specifications, ensuring that every detail is precisely replicated. This level of precision reduces errors and significantly improves product quality. The computer-controlled machines follow detailed instructions, cutting materials with micrometer-level precision. Whether it’s a complex aerospace component or a delicate medical device, custom CNC machining guarantees that each part meets the stringent requirements of its intended application.

4.2 Versatility in Materials

One of the major benefits of custom CNC machining is its ability to work with a wide variety of materials. This versatility allows it to meet the diverse needs of different industries. From metals like aluminum, steel, brass, and titanium to plastics and ceramics, custom CNC machining can handle it all. Metals are commonly used due to their strength, durability, and machinability. For example, aluminum is lightweight and corrosion-resistant, making it ideal for applications where weight is a concern. Steel, on the other hand, offers exceptional strength and hardness, suitable for heavy-duty applications. Plastics are also a popular choice for their flexibility, lightweight nature, and resistance to chemicals. Ceramics are used in applications that require high temperature resistance, wear resistance, and electrical insulation. With such a wide range of materials available, custom CNC machining can create parts for a multitude of industries, including aerospace, automotive, electronics, medical, and consumer products.

4.3 Rapid Prototyping and Short Lead Times

Custom CNC machining allows for quick corrections in designs and fast production turnaround. This is particularly beneficial for rapid prototyping, where engineers and designers need to test and refine their designs quickly. With CNC machining, changes can be made easily and quickly, reducing the time it takes to bring a product from concept to market. Additionally, once the program is set up, the machines can run continuously without the need for constant supervision, further reducing production time. Short lead times are essential in today’s fast-paced business environment, where time-to-market can be a critical factor in a product’s success.

4.4 Cost-Effective Solutions

Custom CNC machining offers cost-effective solutions that can be more economical than traditional manufacturing methods. Although the initial setup cost may be higher, the automated nature of the process reduces labor costs and waste of materials. Custom-tailored solutions ensure that only the necessary materials are used, minimizing waste and reducing costs. Moreover, the high precision and accuracy of CNC machining reduce the need for rework and quality control inspections, further saving time and money. In the long run, custom CNC machining can provide a more cost-effective solution for businesses looking to produce high-quality parts in small to medium quantities.

5、How to Choose a Precision CNC Machining Service Provider?

5.1 Consider Experience and Expertise

When looking for a precision CNC machining service provider, experience and expertise are crucial factors. A provider with a proven track record in serving various industries and applications is more likely to understand the specific requirements of your project. For example, FRIMA Manufacturing is a precision CNC machining service provider that offers CNC manufactured parts and components. They have a full-service shop with capabilities in milling, turning and assembly and serve a variety of industries including aerospace, medical, and automotive. Their state-of-the-art equipment and experienced team allow them to provide high-quality parts and components that meet exact specifications. Another example is Lifeng Metal, which excels in custom fabrication of sheet metal and CNC machining parts. They have rich experiences in serving industries like machinery, electronics, vehicles, home appliance, etc.

5.2 Assess Equipment and Technology

Ensuring the service provider has state-of-the-art CNC machines and advanced manufacturing processes is essential for obtaining high-quality results. Providers like Best Fit Precision parts Co.,Ltd offer services such as advanced die casting solution, high precision CNC turning service, precision CNC machining/milling service, 3D laser cutting service, bending and stamping service, metal fabrication service, welding and assembly service, and quality assurance and logistics service. They have factories in both Kunshan and Shenzhen and an office in Shanghai. Their facilities and advanced technology enable them to meet the diverse needs of customers.

5.3 Check Quality Control Measures

Verify the quality control service process of the provider to guarantee cutting-edge quality in every product. Quality Assurance (QA) and Quality Control (QC) are important aspects of the manufacturing process. QA is a series of activities that ensure product quality throughout the design and development stages, while QC focuses on inspecting and correcting product quality during the manufacturing process. For example, Nejkov LLC monitors and analyses procedures and load of machines to achieve minimum costs while increasing speed and quality. They are proud to have an experienced team of responsible specialists who ensure quality through the use of quality tools from proven suppliers and up-to-date software.

5.4 Evaluate Customer Service and Support

Good communication, fast response times, and engineering support are essential when choosing a precision CNC machining service provider. Providers that offer excellent customer service make customers feel special and ensure a smooth manufacturing process. For instance, in America, customer service continues long after the sale. Many products come with a money-back guarantee and warranties. Stores also offer express lanes for customers with fewer items and allow customers to take their shopping carts out to the parking lot. Customer service representatives are available to answer questions and address concerns. Additionally, companies like FRIMA Manufacturing receive positive feedback from customers like Bill, Tobias, Allan, and Steve for their excellent service and high-quality products.

6、Conclusion

Precision custom CNC machining truly stands as a cornerstone in the modern industrial landscape. It offers a diverse range of benefits and endless possibilities for various industries. Understanding its processes and capabilities is essential for businesses seeking high-quality, custom-made parts.

Whether it’s in the aerospace industry where precision is crucial for aircraft engines and structural parts to ensure safety in flight, or in the medical field where accurate surgical instruments and implants are needed for patient care, precision CNC machining provides the solution. The automotive sector also relies on it for creating precise parts for engines, transmissions, and brakes to enhance vehicle performance and safety.

Not only limited to these major industries, it also serves electronics, home appliances, intelligent robotics, LED lighting, agriculture, and automation equipment. In electronics, it creates precise connectors and enclosures for reliable signal transmission and device durability. Home appliance manufacturing uses it to make motor parts and housing for functionality and durability. In smart robotics, it produces parts for sensors and actuators to enable accurate performance. The LED lighting industry benefits from it for creating heat sinks and housings. In agriculture, it produces durable and precise parts for machinery. And in automation, it creates parts for robots and automated equipment for accurate manufacturing.

By choosing the right service provider, businesses can ensure that their parts are manufactured to the highest quality standards and meet their specific needs. Looking for a provider with extensive experience and expertise, state-of-the-art equipment and technology, robust quality control measures, and excellent customer service is key.

In conclusion, precision custom CNC machining is an invaluable asset for modern manufacturing. It combines high accuracy, flexibility, and cost-effectiveness to meet the diverse demands of different industries. With the right service provider, businesses can achieve their manufacturing goals and stay competitive in today’s market.