What is CNC Metal Machining SDN BHD?

CNC Metal Machining SDN BHD is a renowned company in the field of precision metal machining. Incorporated in 2006, it has steadily grown in both size and strength over the years.

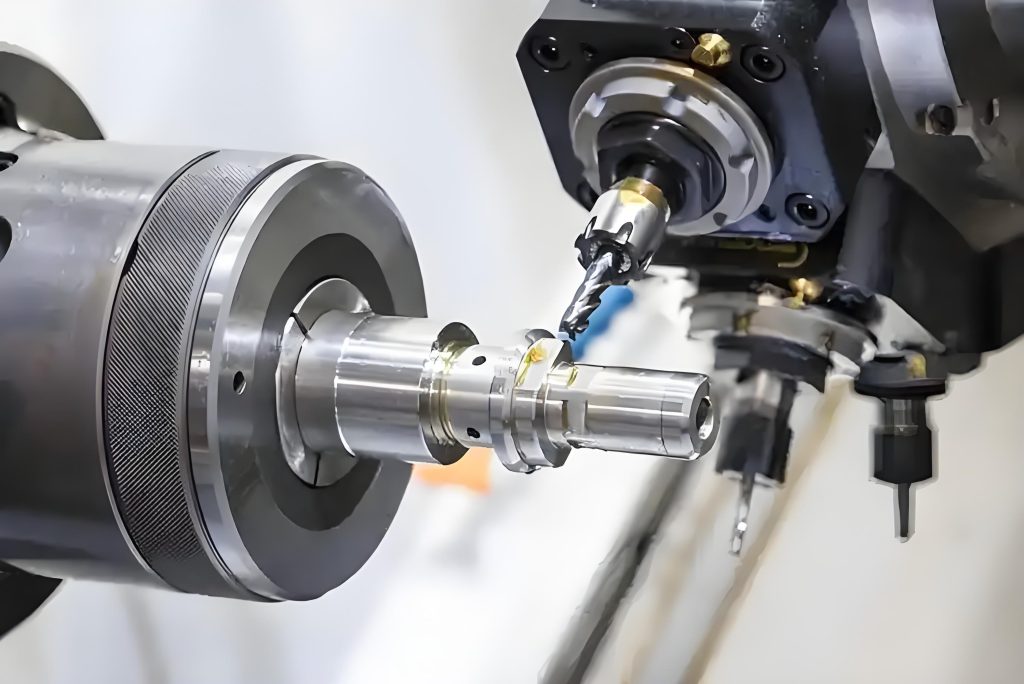

CNC, which stands for Computer Numerical Control, is a widely used technology in precision machining. It enables the logical processing of programs with control codes or other symbolic instructions, decoded by a computer to control various tools such as lathes, milling machines, and grinders. For instance, CNC lathes, CNC milling machines, and CNC boring machines are some of the common tools used in the industry.

The company undertakes machining challenges in precision and semi-precision metal parts and components. It caters to a diverse range of industries including oil and gas, electronics, medical, and precision machinery. The air-conditioned environment and state-of-the-art testing equipment ensure that all specifications and tolerances exceed customer requirements and expectations.

In addition to its in-house capabilities, CNC Metal Machining SDN BHD has key partnerships with suppliers who provide welding, coating, and testing processes. This one-stop service approach enhances the company’s overall production capabilities.

The vision of CNC Metal Machining SDN BHD is to be a leading global technical corporation, distinguished by the quality and precision of its products. The mission is to deliver value to customers and shareholders by providing world-class technical solutions. This is achieved through being a preferred provider of technical services, integrated systems solutions, and precision products; having a diverse team of highly trained and talented professionals; being an employer of choice that fosters a culture of dedication, respect, and continuous improvement; and always focusing on customer satisfaction with uncompromising integrity.

With its commitment to quality and innovation, CNC Metal Machining SDN BHD is well-positioned to meet the evolving needs of its customers and contribute to the growth of the precision metal machining industry.

The Importance of Rapid and Efficient CNC Machining

Rapid and efficient CNC machining is of utmost importance in today’s industrial landscape. It serves as a cornerstone for numerous industries, enabling the production of high-quality metal parts with unrivaled precision and speed. In an era driven by technological advancements, CNC machining has become not only more accessible but also significantly more efficient.

Features of Rapid and Efficient CNC Machining

- Automatic tool-changing capability for a variety of machining operations: This feature is a game-changer in the world of CNC machining. With a variety of tools available in the tool magazine or drum, the machine can quickly and seamlessly switch between different tools as per the requirements of various machining operations. For instance, when transitioning from milling to drilling or turning, the automatic tool changer rotates to the appropriate position and selects the required tool, minimizing downtime and maximizing productivity.

- State-of-the-art precision CNC machining in an air-conditioned environment: The air-conditioned environment plays a crucial role in ensuring the accuracy and quality of CNC machining. It helps to maintain a stable temperature and humidity level, which is essential for the precise movement of the machine’s components. This stability reduces the risk of thermal expansion and contraction, ensuring that the machined parts meet the strictest tolerance requirements. Additionally, the advanced testing equipment in this environment further guarantees that all specifications and tolerances exceed customer expectations.

- Enhanced production capabilities through key partnerships with suppliers: Collaboration with suppliers is a key factor in enhancing the production capabilities of CNC machining. By partnering with suppliers who provide welding, coating, and testing processes, companies like CNC Metal Machining SDN BHD can offer a one-stop service approach. This not only streamlines the production process but also ensures that every aspect of the manufacturing process is carried out with the highest level of quality and expertise. For example, after the machining process, the parts can be sent for welding to ensure structural integrity, followed by coating for added protection and aesthetic appeal. The final testing process then validates the quality and performance of the finished product, providing customers with a reliable and high-quality end product.

Products and Services Offered by CNC Metal Machining SDN BHD

CNC Metal Machining SDN BHD offers a wide range of high-quality products and services that cater to diverse industries.

- Precision metal parts and components for oil and gas, electronics, medical, and precision machinery industries.

- The company specializes in manufacturing precision metal parts and components that are crucial for the smooth operation of various industries. In the oil and gas industry, these parts play a vital role in ensuring the efficiency and safety of drilling, extraction, and transportation processes. For example, precision valves and fittings are essential for controlling the flow of oil and gas.

- In the electronics industry, the company produces metal components for circuit boards, connectors, and enclosures. These parts must meet strict tolerances to ensure reliable electrical connections and protect sensitive electronic components.

- The medical industry also relies on precision metal parts for medical devices and instruments. For instance, surgical tools and implants require high-quality metal components that are biocompatible and can withstand sterilization processes.

- In the precision machinery industry, CNC Metal Machining SDN BHD provides metal parts for machines such as lathes, milling machines, and grinders. These parts must be extremely accurate to ensure the proper functioning of the machinery and produce high-quality products.

- Welding, coating, and testing processes as part of one-stop services.

- In addition to manufacturing precision metal parts, CNC Metal Machining SDN BHD offers a comprehensive range of one-stop services. This includes welding, coating, and testing processes.

- The welding services provided by the company ensure the structural integrity of the metal parts. Whether it’s for joining two metal pieces or repairing damaged parts, the company’s experienced welders use advanced welding techniques to achieve strong and durable welds.

- Coating services add an extra layer of protection and aesthetic appeal to the metal parts. Different types of coatings can be applied depending on the specific requirements of the customer. For example, anti-corrosion coatings are used in harsh environments to prevent rust and deterioration.

- The testing processes carried out by the company ensure that all products meet the highest quality standards. Advanced testing equipment is used to measure dimensions, check for defects, and verify the performance of the metal parts. This includes services such as dimensional inspection, material testing, and functional testing.

- By offering these one-stop services, CNC Metal Machining SDN BHD simplifies the procurement process for customers and ensures that every aspect of the manufacturing process is carried out with the highest level of quality and expertise.

Comparing Different Types of CNC Machining

SAT vocabulary analysis of terms related to speed: fast, quick, and rapid.

In the context of CNC machining, the terms fast, quick, and rapid all convey a sense of speed. However, there are subtle differences among them. “Fast” implies a high rate of movement or completion, emphasizing swiftness. For example, a fast CNC machining process might complete a complex part in a relatively short amount of time. “Quick” often suggests a sudden or prompt action. In CNC machining, a quick adjustment to a tool setting can save valuable production time. “Rapid” emphasizes a continuous and intense speed. A rapid CNC machining operation can churn out multiple parts in a short span, meeting the demands of high-volume production.

Understanding the differences between various CNC machining processes and their applications.

There are several different types of CNC machining processes, each with its own unique characteristics and applications. For instance, milling is a common CNC machining process used to create complex shapes by removing material from a workpiece. It’s ideal for producing parts with precise dimensions and intricate geometries. Turning, on the other hand, is used to create cylindrical shapes by rotating the workpiece while a cutting tool removes material. This process is commonly used in the production of shafts, pins, and other cylindrical components. Drilling is used to create holes in a workpiece, and it can be performed with high precision using CNC machines. In addition to these main processes, there are also specialized CNC machining processes such as grinding, which is used to achieve extremely smooth surfaces, and electrical discharge machining (EDM), which is used to create complex shapes in hard materials.

The choice of CNC machining process depends on several factors, including the material being machined, the complexity of the part, and the required production volume. For example, in the aerospace industry, where parts need to be extremely precise and lightweight, advanced CNC machining processes such as five-axis milling are often used. In the automotive industry, high-volume production of relatively simple parts may call for more efficient processes like high-speed turning.

CNC machining is also widely used in the medical field, where precision is crucial. Parts for medical devices and implants often require complex geometries and tight tolerances, which can be achieved through CNC machining. Additionally, in the electronics industry, CNC machining is used to produce parts for circuit boards, connectors, and enclosures. The ability to create precise and consistent parts is essential for ensuring reliable electrical connections and protecting sensitive electronic components.

The Future of CNC Metal Machining SDN BHD

In today’s rapidly evolving industrial landscape, CNC Metal Machining SDN BHD is positioned at the forefront of precision metal machining, ready to shape the future of the industry. As technology continues to advance, the demand for high-precision metal parts is on the rise, and CNC Metal Machining SDN BHD is well-equipped to meet this growing demand.

The company’s focus on quality and precision is unwavering. With state-of-the-art testing equipment and an air-conditioned environment for machining operations, CNC Metal Machining SDN BHD ensures that every part produced meets the strictest tolerance requirements. This commitment to excellence not only sets the company apart from its competitors but also builds trust with customers and shareholders.

CNC Metal Machining SDN BHD’s partnerships with suppliers play a crucial role in its success. By collaborating with welding, coating, and testing providers, the company can offer a comprehensive one-stop service approach. This streamlines the production process and ensures that every aspect of manufacturing is carried out with the highest level of quality and expertise.

Looking ahead, CNC Metal Machining SDN BHD is poised to expand its global reach. With its reputation for quality and precision, the company is likely to attract more customers from diverse industries around the world. This will not only drive growth but also contribute to the development of the precision metal machining industry on a global scale.

As the industry continues to evolve, CNC Metal Machining SDN BHD will likely invest in research and development to stay ahead of the curve. This could involve exploring new machining techniques, materials, and applications to meet the changing needs of customers.

In conclusion, the future of CNC Metal Machining SDN BHD looks bright. With its commitment to quality, innovation, and customer satisfaction, the company is well-positioned to become a leading global technical corporation in the field of precision metal machining.