In the fast-paced world of manufacturing, the ability to quickly and accurately produce prototypes is crucial for product development and innovation. Prototype CNC machining services have emerged as a cornerstone in this process, leveraging advanced technology to create precise, functional models that can be used for testing, validation, and market feedback. This article delves into the basics of CNC machining, the current market landscape, technological advancements, and how Rapidefficient stands out in the realm of precision CNC machining.

Understanding the Basics of CNC Machining

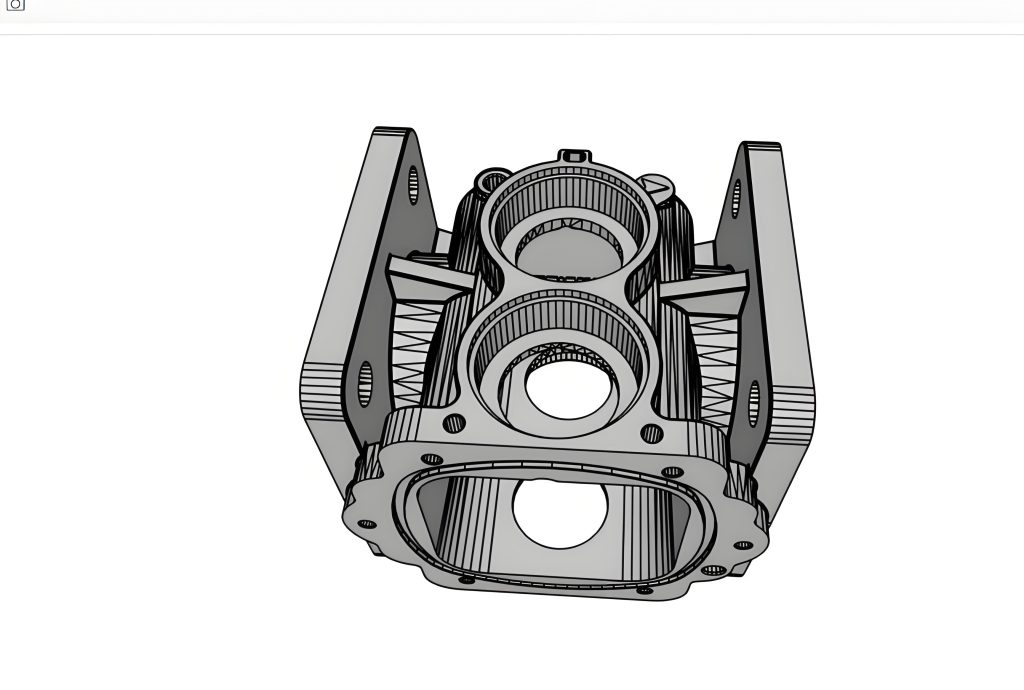

CNC, short for Computer Numerical Control, machining is a subtractive manufacturing process that uses computer-controlled machinery to cut away material from a block or workpiece to create a desired shape or object. The process begins with a CAD (Computer-Aided Design) file, which outlines the design specifications of the prototype. This file is then converted into a series of machine-readable instructions, known as G-code, that direct the CNC machine’s tools to move in precise patterns.

CNC machines come in various forms, including milling machines, lathes, and grinders, each designed for specific types of material removal and shaping tasks. These machines are equipped with high-precision tools and sensors that ensure the accuracy and repeatability of the cutting process. The integration of CNC technology with advanced software has revolutionized the prototyping industry, enabling manufacturers to produce complex designs with unparalleled precision and speed.

The Market Landscape of Prototype CNC Machining Services

The demand for prototype CNC machining services has surged in recent years, driven by the rapid pace of product development cycles and the increasing complexity of designs. Manufacturers across various industries, from automotive to aerospace, medical devices to consumer electronics, rely on prototype CNC machining to bring their innovative ideas to life.

As the market grows, so does the competition. Numerous service providers have entered the fray, offering a range of capabilities and services. However, not all providers are created equal. The quality of the prototypes, turnaround times, and overall customer experience can vary widely. This makes it essential for businesses to carefully evaluate their options and choose a service provider that aligns with their specific needs and requirements.

Technological Innovations Shaping the Future

The prototyping industry is continuously evolving, driven by technological innovations that enhance the capabilities and efficiency of CNC machining. Here are some of the key trends shaping the future of prototype CNC machining services:

Additive Manufacturing Integration: While traditionally a subtractive process, the integration of additive manufacturing (3D printing) technologies with CNC machining is becoming increasingly common. This hybrid approach allows manufacturers to leverage the strengths of both technologies, creating prototypes that are both functional and aesthetically pleasing.

Automation and AI: The incorporation of automation and artificial intelligence (AI) in CNC machining is transforming the industry. AI-driven algorithms can optimize toolpaths, reduce machining time, and improve surface finish. Automation, on the other hand, minimizes human error and enhances productivity, enabling manufacturers to produce prototypes with consistent quality and at a faster rate.

Material Advancements: The range of materials suitable for CNC machining is constantly expanding. From traditional metals like aluminum and steel to advanced composites and exotic alloys, manufacturers now have a wider choice of materials to suit their specific design requirements. This diversity in material options allows for the creation of prototypes that are tailored to perform under various conditions and environments.

Cloud-Based Manufacturing Platforms: The advent of cloud-based manufacturing platforms has democratized access to prototype CNC machining services. These platforms enable businesses to connect with a global network of service providers, compare quotes, and manage projects from anywhere in the world. They also facilitate collaboration between design teams and manufacturers, streamlining the prototyping process and accelerating time-to-market.

Rapidefficient: A Leader in Precision CNC Machining

In the crowded market of prototype CNC machining services, Rapidefficient stands out as a leader in precision manufacturing. With a focus on delivering high-quality prototypes, fast turnaround times, and exceptional customer service, Rapidefficient has earned a reputation for excellence in the industry.

Rapidefficient’s commitment to cutting-edge technology is evident in its advanced CNC machining capabilities. The company invests in the latest machinery and software to ensure that its clients receive the most accurate and efficient prototyping services available. Rapidefficient’s team of experienced engineers and machinists is dedicated to collaborating with clients to understand their unique needs and deliver customized solutions that exceed expectations.

One of Rapidefficient’s key strengths lies in its expertise in CNC aluminum machining. With a deep understanding of the properties and behaviors of aluminum, Rapidefficient is able to produce prototypes that are lightweight, durable, and aesthetically pleasing. This expertise has made Rapidefficient a go-to partner for businesses in industries that rely on aluminum components, such as aerospace, automotive, and consumer electronics.

The Value of Rapidefficient’s Prototype CNC Machining Services

Rapidefficient’s prototype CNC machining services offer numerous benefits to businesses seeking to accelerate their product development processes:

Reduced Time-to-Market: Rapidefficient’s fast turnaround times enable businesses to get their prototypes in hand quickly, allowing for earlier testing, validation, and feedback. This acceleration of the prototyping phase can significantly shorten the overall product development cycle, enabling businesses to bring innovative products to market faster.

Cost-Effective Solutions: By leveraging advanced technology and efficient processes, Rapidefficient is able to offer competitive pricing for its prototype CNC machining services. This cost-effectiveness allows businesses to allocate more resources towards other critical areas of their product development efforts, such as research and marketing.

High-Quality Prototypes: Rapidefficient’s commitment to precision and quality ensures that its clients receive prototypes that are accurate, functional, and durable. These prototypes can be used for a variety of purposes, including testing, validation, and market feedback, providing businesses with valuable insights that can inform and improve their product designs.

Customized Solutions: Rapidefficient’s team of experienced engineers and machinists is dedicated to working closely with clients to understand their unique needs and deliver customized solutions. This personalized approach ensures that businesses receive prototypes that are tailored to their specific requirements, enhancing the overall success of their product development efforts.

Conclusion: Choosing Rapidefficient for Your Next Prototype Project

In the competitive landscape of product development, having access to cutting-edge prototype CNC machining services is crucial. Rapidefficient, with its advanced technology, experienced team, and commitment to precision and quality, is an ideal partner for businesses seeking to accelerate their product development processes and bring innovative products to market.

Whether you’re in the automotive, aerospace, medical device, or consumer electronics industry, Rapidefficient’s expertise in CNC aluminum machining and prototype CNC machining can help you bring your innovative ideas to life. With fast turnaround times, competitive pricing, and customized solutions, Rapidefficient is poised to become your trusted partner in the prototyping phase of your next product development project.

To learn more about Rapidefficient’s prototype CNC machining services and how they can benefit your business, visit our website or contact us today. We look forward to collaborating with you to create the prototypes that will propel your products to success.