In the dynamic world of manufacturing, precision is paramount. From aerospace components to intricate automotive parts, the demand for flawlessly crafted products has never been higher. At the heart of this evolution lies Computer Numerical Control (CNC) precision machining, a technology that has revolutionized the industry. Today, we delve into the intricacies of CNC machining, its current market landscape, and the remarkable strides made by Rapidefficient in this field. Our journey begins with understanding the basics of CNC machining and its unparalleled potential.

The Fundamentals of CNC Precision Machining

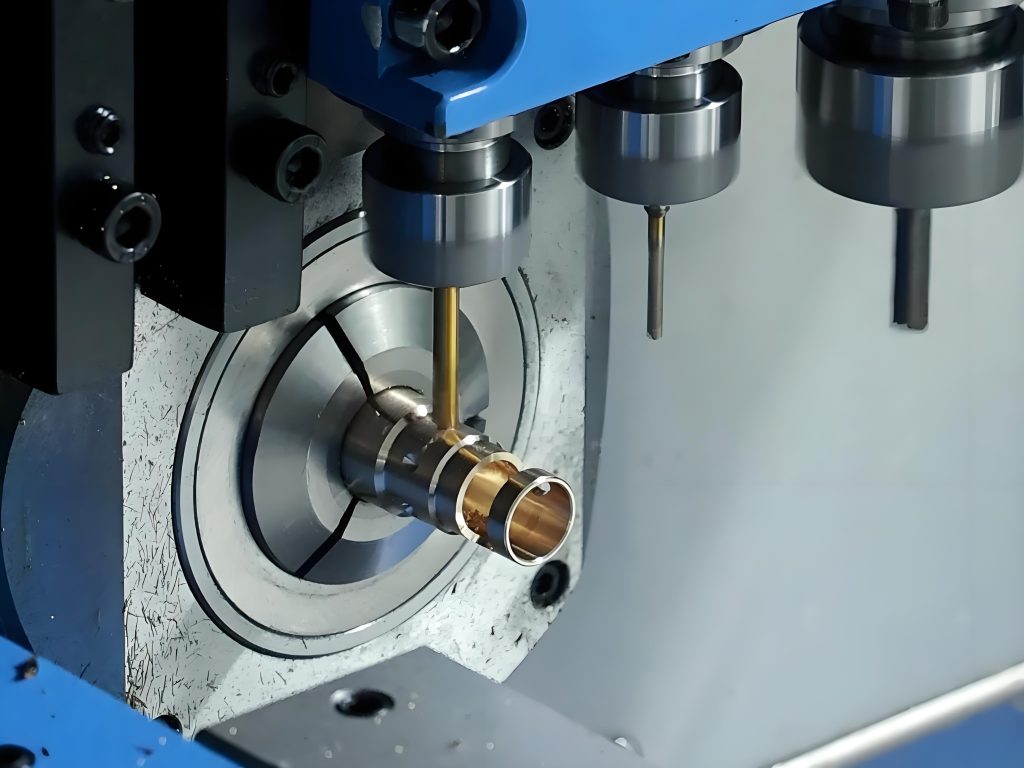

CNC precision machining involves the use of computer-controlled tools to shape and fabricate components from various materials such as metals, plastics, and composites. The process starts with a digital design, which is then translated into precise machine instructions. These instructions guide the CNC machine through a series of cutting, drilling, grinding, and other fabrication processes, ensuring unparalleled accuracy and repeatability.

The core advantage of CNC machining lies in its ability to automate complex manufacturing tasks with minimal human intervention. This not only enhances productivity but also reduces the margin for error, resulting in higher quality finished products. Moreover, the adaptability of CNC machines allows for quick adjustments and modifications, catering to a wide range of design specifications and production needs.

The Market Landscape of CNC Precision Machining

The global CNC machining market is experiencing significant growth, fueled by advancements in technology and the increasing demand for precision-engineered components across various industries. Key drivers include the surge in automation within manufacturing processes, the evolution of advanced materials, and the rising emphasis on quality and efficiency.

In this competitive landscape, CNC machine manufacturers are continuously innovating to stay ahead. This includes the development of more sophisticated software, enhancements in machine tool design, and the integration of smart technologies such as IoT and AI. These advancements are crucial for achieving higher levels of precision, productivity, and cost-effectiveness.

Rapidefficient: A Pioneer in CNC Precision Machining

Rapidefficient stands out as a leading provider of CNC precision machining services, known for its commitment to excellence and unwavering focus on customer satisfaction. The company leverages state-of-the-art equipment and cutting-edge technology to deliver unparalleled precision and efficiency in its manufacturing processes.

1. Advanced Machinery and Tooling

Rapidefficient’s arsenal of high-performance CNC machines includes the latest multi-axis milling and turning centers, capable of handling complex geometries and tight tolerances. The company invests heavily in upgrading its machinery to ensure it remains at the forefront of technological advancements. This dedication to equipment excellence ensures that Rapidefficient can meet the most demanding specifications and production timelines.

2. Expertise in Materials Handling

CNC machining is not just about the machines; it’s also about the materials. Rapidefficient possesses extensive expertise in handling a wide range of materials, from traditional metals like aluminum, steel, and titanium to advanced composites and plastics. The company’s in-depth understanding of material properties and machining characteristics allows it to optimize processes and achieve superior results.

3. Customized Solutions

Every manufacturing project is unique, and Rapidefficient understands this well. The company offers customized solutions tailored to meet the specific needs of its clients. From design consultation and prototyping to full-scale production and quality assurance, Rapidefficient provides comprehensive support throughout the entire manufacturing lifecycle. This personalized approach ensures that every project is executed with precision and efficiency.

4. Quality Assurance and Control

Quality is the cornerstone of Rapidefficient’s operations. The company implements rigorous quality control measures throughout its manufacturing processes, including in-process inspections, final inspections, and third-party certifications. This commitment to quality ensures that every product meets or exceeds customer expectations and industry standards.

The Value of Rapidefficient in the CNC Precision Machining Market

Rapidefficient’s commitment to excellence is not just a slogan; it’s a way of life. The company’s unwavering focus on precision, efficiency, and customer satisfaction has earned it a reputation as a trusted partner in the CNC precision machining industry. Here are some of the key benefits that Rapidefficient brings to its clients:

1. Competitive Pricing

Rapidefficient’s efficient manufacturing processes and advanced machinery allow it to offer competitive pricing without compromising on quality. This makes it an attractive option for businesses looking to optimize their production costs while maintaining high standards.

2. Shorter Lead Times

With its high-performance machinery and streamlined workflows, Rapidefficient is able to reduce lead times and deliver products faster. This agility is crucial in today’s fast-paced business environment, where time-to-market can be a significant competitive advantage.

3. Technical Expertise

Rapidefficient’s team of highly skilled engineers and technicians possesses deep technical expertise in CNC precision machining. This expertise enables the company to provide valuable insights and recommendations that can help clients optimize their designs and manufacturing processes.

4. Customer-Centric Approach

Rapidefficient’s customer-centric approach ensures that its clients are always at the forefront of its operations. The company listens to its clients’ needs, understands their challenges, and works tirelessly to provide solutions that exceed their expectations. This commitment to customer satisfaction has earned Rapidefficient a loyal customer base that spans various industries.

The Future of CNC Precision Machining with Rapidefficient

As the manufacturing industry continues to evolve, so too must the technologies and practices that drive it. Rapidefficient remains at the forefront of this evolution, continuously investing in research and development to stay ahead of the curve. Here’s a glimpse into the future of CNC precision machining with Rapidefficient:

1. Smart Manufacturing

The integration of smart technologies such as IoT, AI, and machine learning will play a pivotal role in shaping the future of CNC precision machining. Rapidefficient is actively exploring these technologies to enhance its manufacturing processes, improve efficiency, and reduce waste.

2. Sustainable Manufacturing

Sustainability is becoming increasingly important in today’s world. Rapidefficient is committed to reducing its environmental impact through sustainable manufacturing practices. This includes optimizing material usage, minimizing waste, and implementing energy-efficient processes.

3. Collaborative Robotics

The advent of collaborative robots (cobots) is transforming manufacturing workflows. Rapidefficient is exploring the potential of cobots to work alongside its human team members, enhancing safety, productivity, and flexibility.

Conclusion: Embrace the Future with Rapidefficient

In conclusion, the world of CNC precision machining is rapidly evolving, and Rapidefficient is poised to lead the charge. With its advanced machinery, technical expertise, and customer-centric approach, Rapidefficient offers unparalleled precision and efficiency in manufacturing.

As we look to the future, Rapidefficient will continue to innovate and adapt, embracing new technologies and practices that push the boundaries of what’s possible. By partnering with Rapidefficient, businesses can stay ahead of the curve, optimize their manufacturing processes, and deliver exceptional products to their customers.