In the realm of modern manufacturing, the debate between precision CNC machining and general CNC machining often arises. Both processes utilize Computer Numerical Control (CNC) machines to automate the manufacturing of parts and components, but they differ significantly in terms of accuracy, capability, and application. This article delves into the nuances of these two methods, exploring their fundamental concepts, market impacts, technological advancements, and, importantly, the role Rapidefficient plays in the CNC machining landscape.

CNC Machining: The Foundation

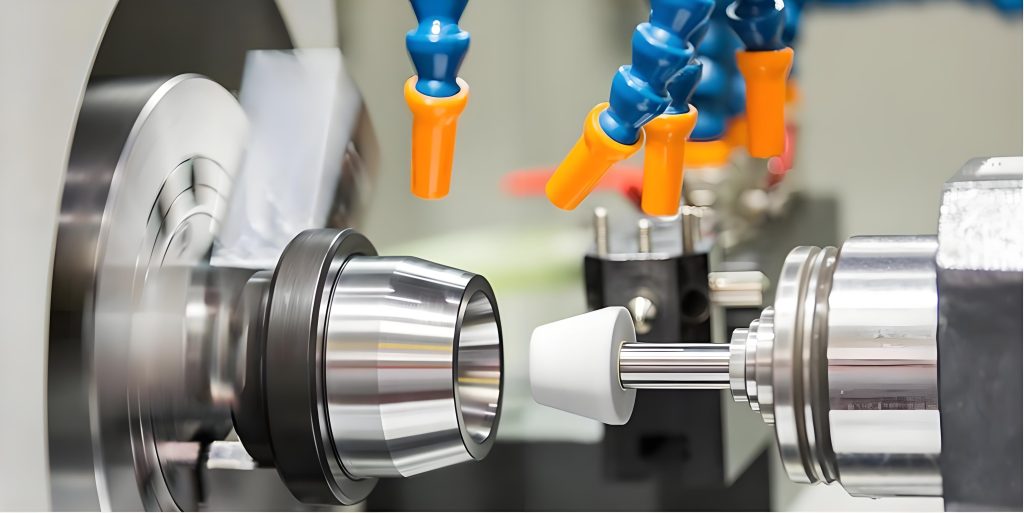

CNC machining is a subtractive manufacturing process that involves the use of computer-controlled tools to remove material from a workpiece, creating a desired shape or part. The process is highly versatile, capable of producing intricate designs and complex geometries with remarkable precision. The advent of CNC technology has revolutionized manufacturing, transforming it from a labor-intensive industry to one that relies heavily on automation and digitalization.

The market for CNC machining is thriving, driven by the increasing demand for precision-engineered components across various industries, including aerospace, automotive, medical, and electronics. As manufacturers strive to meet these demands, the choice between precision and general CNC machining becomes crucial.

Precision CNC Machining: The Art of Accuracy

Precision CNC machining stands out for its unparalleled accuracy and repeatability. This method employs high-precision machinery, tools, and measurement systems to ensure that every part produced meets strict tolerances and specifications. The focus on accuracy is achieved through a combination of advanced machinery, rigorous quality control measures, and skilled operators.

One of the key benefits of precision CNC machining is its ability to produce parts with tight tolerances, often measured in micrometers. This level of accuracy is essential in industries where performance and reliability are paramount, such as aerospace and medical device manufacturing. Precision CNC machining also allows for the production of complex geometries and intricate details, enabling manufacturers to create parts that are both functional and aesthetically pleasing.

Moreover, precision CNC machining is often paired with other advanced manufacturing techniques, such as 5-axis machining, which further enhances its capabilities. 5-axis machines can move in five directions simultaneously, providing greater flexibility and enabling the production of parts with complex shapes and undercuts that would be difficult or impossible to achieve with traditional 3-axis machines.

General CNC Machining: Versatility and Efficiency

General CNC machining, on the other hand, offers a broader range of capabilities and is more suited to applications where precision is not the primary concern. This method typically employs standard machinery and tools, allowing for the production of a wider variety of parts and components at a lower cost.

General CNC machining is highly versatile, capable of handling a diverse range of materials, including metals, plastics, and composites. It is also well-suited to high-volume production runs, where efficiency and cost-effectiveness are critical. Manufacturers often rely on general CNC machining for tasks such as prototyping, low-volume production, and the manufacturing of components that do not require the same level of precision as those produced through precision CNC machining.

However, it is important to note that general CNC machining does not necessarily compromise on quality. While it may not achieve the same level of accuracy as precision CNC machining, it still adheres to strict quality control standards to ensure that parts meet the required specifications.

Technological Advancements and Market Impacts

The CNC machining industry is constantly evolving, driven by technological advancements and innovations. Advances in machine design, tool materials, and software have significantly improved the capabilities and accuracy of both precision and general CNC machining.

For example, the development of high-speed machining (HSM) technology has enabled manufacturers to produce parts faster and more efficiently while maintaining high levels of accuracy. HSM machines operate at higher spindle speeds and feed rates, reducing cycle times and improving productivity. Similarly, the adoption of additive manufacturing (AM) technologies, such as 3D printing, has expanded the range of applications for CNC machining, enabling the production of complex geometries and custom parts that were previously impossible to create.

These technological advancements have had a profound impact on the market, driving competition and fostering innovation. Manufacturers are increasingly investing in advanced CNC machinery and software to stay ahead of the curve and meet the evolving demands of their customers.

Rapidefficient: Leading the Way in CNC Machining

Rapidefficient stands out as a leading provider of precision CNC machining services, offering a wide range of capabilities and expertise to meet the needs of customers across various industries. With a focus on accuracy, quality, and efficiency, Rapidefficient has established itself as a trusted partner in the manufacturing sector.

Rapidefficient’s precision CNC machining services are supported by a team of highly skilled operators and engineers who possess extensive knowledge and experience in the field. The company’s advanced machinery and tools, combined with its rigorous quality control measures, ensure that every part produced meets the highest standards of accuracy and reliability.

In addition to precision CNC machining, Rapidefficient also offers general CNC machining services, catering to customers who require a broader range of capabilities and cost-effective solutions. The company’s versatile approach enables it to provide tailored solutions that meet the unique needs of each customer, regardless of their industry or application.

Rapidefficient’s commitment to excellence extends beyond its manufacturing capabilities. The company’s customer service team is dedicated to providing personalized support and guidance, ensuring that customers receive the best possible experience from the moment they inquire about services until the final delivery of their parts.

Conclusion: Precision vs. General CNC Machining – Finding the Right Balance

In conclusion, the debate between precision CNC machining and general CNC machining is not about which method is superior, but rather about finding the right balance for each application. Precision CNC machining offers unparalleled accuracy and repeatability, making it ideal for industries where performance and reliability are paramount. General CNC machining, on the other hand, provides a broader range of capabilities and cost-effective solutions, making it well-suited to applications where precision is not the primary concern.

As the manufacturing industry continues to evolve, the role of CNC machining will become increasingly important. Manufacturers will need to stay ahead of the curve by investing in advanced machinery, software, and expertise to meet the evolving demands of their customers. Rapidefficient is well-positioned to support this evolution, offering a wide range of precision and general CNC machining services that cater to the unique needs of customers across various industries.

For those looking to explore the potential of precision CNC machining or general CNC machining, Rapidefficient invites you to learn more about our services and capabilities. With a focus on accuracy, quality, and efficiency, we are confident that we can provide the solutions you need to take your manufacturing projects to the next level. Contact us today to discuss your requirements and see how we can help you achieve your manufacturing goals