Introduction

The manufacturing of irregularly shaped parts presents unique challenges to engineers, designers, and manufacturers. Unlike standard geometries, irregular parts require specialized processing techniques and technologies to achieve precision, efficiency, and cost-effectiveness. With the rise of complex industrial applications, from aerospace to automotive and electronics, irregularly shaped parts are increasingly in demand. In this article, we will explore the core technologies used for processing irregular parts, the challenges faced during manufacturing, and potential solutions to overcome these obstacles.

1. Introduction to Irregularly Shaped Parts

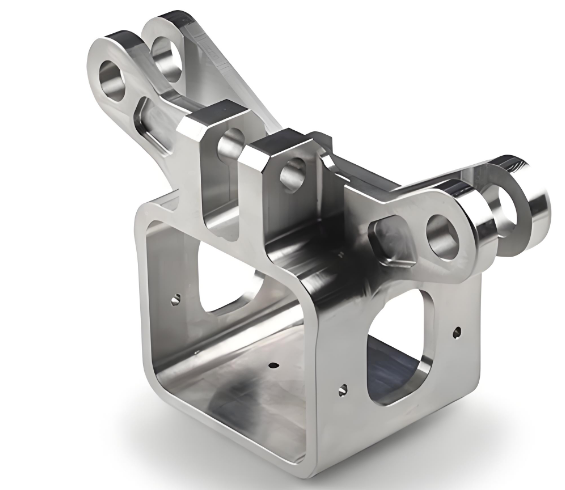

Irregularly shaped parts are components that do not conform to traditional, easily measurable geometries such as circles, squares, or rectangles. These parts often possess complex curves, angles, or contours that challenge conventional machining methods. Due to their uniqueness, these parts are used in industries that demand high precision and specialized manufacturing processes. Examples include turbine blades, automotive brackets, and electronic enclosures.

2. Processing Technologies for Irregularly Shaped Parts

To effectively process irregularly shaped parts, manufacturers rely on several advanced technologies, each suited to specific types of components and materials.

CNC Machining

Computer Numerical Control (CNC) machining is one of the most commonly used methods for processing irregularly shaped parts. With high precision and flexibility, CNC machines can be programmed to create intricate geometries by controlling the movement of tools along multiple axes. This technology is ideal for creating prototypes or small-batch productions of complex parts.

Additive Manufacturing (3D Printing)

Additive manufacturing, or 3D printing, allows for the creation of irregular parts by adding material layer by layer. This technology is particularly useful for creating parts with complex internal structures or intricate designs that would be impossible or time-consuming to produce using traditional methods. Materials such as metal, plastic, and ceramics can be used, offering a wide range of applications across various industries.

Laser Cutting and Engraving

Laser cutting is a precise method used for cutting and engraving irregularly shaped parts from sheets of material. Laser technology can produce highly detailed, accurate cuts with minimal material waste. It is suitable for materials like metals, plastics, and wood, making it a versatile tool in irregular part manufacturing.

Electrochemical Machining (ECM)

Electrochemical machining uses electrical currents to remove material from a workpiece. It is a non-traditional machining process that is often employed for high-precision workpieces made from hard materials. ECM is particularly effective in machining irregular shapes in complex geometries while maintaining a high level of surface finish.

3. Key Challenges in Irregular Parts Processing

While various technologies enable the creation of irregularly shaped parts, manufacturers face several challenges during the production process.

Precision and Tolerances

Achieving tight tolerances and precision is one of the biggest challenges in irregular parts manufacturing. The more complex the shape, the more difficult it is to maintain exact specifications throughout the machining process. Deviations from the intended geometry can result in costly rework or even part failure.

Material Properties

Irregularly shaped parts are often made from advanced materials, including alloys, composites, and ceramics. These materials may have specific challenges such as high hardness, brittleness, or difficulty in handling, making them challenging to process. Understanding and adapting to the material properties is essential to ensuring quality results.

Tool Wear and Maintenance

The complexity of irregular shapes often places significant stress on cutting tools. This can lead to rapid wear, requiring frequent tool changes and increasing the overall cost and downtime of the manufacturing process. Managing tool wear and optimizing tool life is critical to improving efficiency.

Setup Complexity and Time

Setting up machines for irregular parts processing is often more time-consuming and complicated compared to conventional parts. Multiple fixtures and adjustments are typically required to ensure the part is held securely and accurately throughout the process. This setup complexity can lead to longer cycle times and higher production costs.

Cost and Material Waste

Because of the intricate shapes and potential for material wastage, irregular parts manufacturing can be costly. Additionally, custom fixtures or specialized tools may be required, increasing capital expenses. Efficient material usage and cost-effective production methods are crucial in reducing overall manufacturing costs.

4. Emerging Technologies in Irregular Parts Manufacturing

To address the challenges of irregular part manufacturing, the industry has turned to emerging technologies.

Smart Manufacturing and Automation

Smart manufacturing technologies, including robotics and IoT (Internet of Things), are making it possible to automate the production of irregularly shaped parts. Automation can improve consistency, reduce human error, and streamline production times.

Hybrid Manufacturing

Hybrid manufacturing combines traditional machining with additive manufacturing techniques. This approach allows manufacturers to take advantage of the strengths of both methods, resulting in parts with complex geometries and high precision.

AI and Machine Learning Integration

Artificial intelligence and machine learning are being integrated into manufacturing systems to improve process optimization and predict tool wear. AI algorithms can analyze real-time data to fine-tune operations, leading to better quality and reduced costs.

5. Case Studies and Real-World Applications

Aerospace Industry

In the aerospace industry, irregularly shaped parts like turbine blades, engine components, and structural elements are commonplace. These parts often require high-precision machining and special materials to withstand extreme conditions. Advanced CNC and additive manufacturing technologies are widely used in this sector to produce lightweight, strong components.

Automotive Manufacturing

Automotive manufacturers use irregular parts for various applications, such as brackets, engine components, and custom fittings. The need for high precision, especially in safety-critical components, makes advanced machining technologies essential for meeting the stringent requirements of this industry.

Electronics and Custom Devices

Custom electronic enclosures, heat sinks, and circuit boards often feature irregular shapes. As the demand for compact, high-performance devices increases, manufacturers are relying on innovative processing technologies to create parts that fit unique and complex designs.

6. Future Trends and Innovations in Irregular Parts Processing

As industries continue to demand more complex and efficient manufacturing techniques, the future of irregular parts processing looks promising. The continued evolution of AI, automation, and hybrid manufacturing will enable faster, more cost-effective production. Additionally, advancements in material science will further expand the range of materials that can be processed with precision.

7. Conclusion

The manufacturing of irregularly shaped parts is a dynamic field that requires specialized technologies and innovative approaches to address the inherent challenges. With the advent of advanced technologies such as CNC machining, additive manufacturing, and smart manufacturing, the production of complex, high-precision parts is becoming more accessible. However, challenges remain in terms of cost, tool wear, and setup complexity. As the industry continues to evolve, the development of hybrid processes and AI-driven solutions will likely play a significant role in overcoming these obstacles and advancing the capabilities of irregular parts manufacturing.