In today’s advanced manufacturing landscape, CNC machine tools play a crucial role in achieving precision and efficiency. One of the key aspects that sets modern CNC machining apart is the linkage control and multi-axis machining capabilities. In this article, we will explore what exactly linkage control and multi-axis machining are and how they contribute to the world of CNC machining.

I. Understanding CNC Machine Tools

CNC (Computer Numerical Control) machine tools are automated machines that use computer programs to control the movement of cutting tools. These machines can perform a wide range of operations, including milling, turning, drilling, and grinding. The precision and repeatability offered by CNC machine tools make them essential in various industries such as aerospace, automotive, and electronics.

II. Linkage Control in CNC Machine Tools

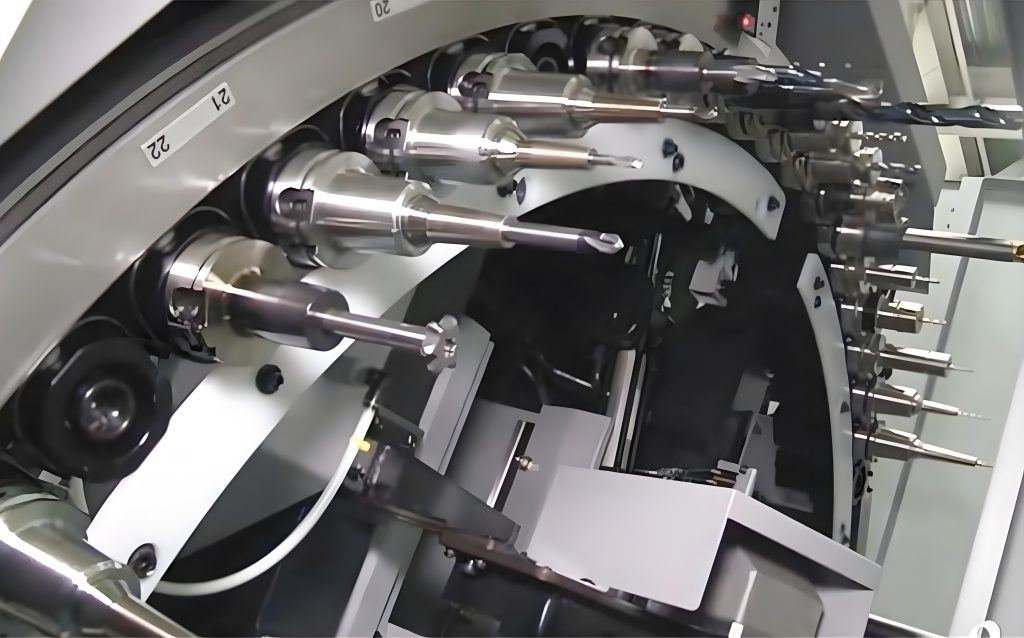

Linkage control refers to the coordinated movement of multiple axes on a CNC machine tool. This allows for complex shapes and geometries to be machined with high accuracy. For example, in a five-axis CNC machine, the tool can move in three linear axes (X, Y, and Z) as well as two rotational axes (A and B or C). The linkage control system ensures that these axes move in a synchronized manner to achieve the desired machining result.

One of the main advantages of linkage control is the ability to machine parts with complex contours and undercuts. Without linkage control, it would be extremely difficult or even impossible to achieve such geometries. Additionally, linkage control can improve machining efficiency by reducing the number of setups and tool changes required.

III. Multi-Axis Machining

Multi-axis machining involves using more than three axes to machine a part. As mentioned earlier, five-axis machining is a common form of multi-axis machining. However, there are also seven-axis and even nine-axis CNC machine tools available for specialized applications.

The increased number of axes in multi-axis machining provides several benefits. First, it allows for more complex geometries to be machined in a single setup. This reduces production time and improves part quality by minimizing errors caused by multiple setups. Second, multi-axis machining can improve tool access to the workpiece, enabling more efficient cutting and reducing tool wear.

IV. The Importance of Linkage Control and Multi-Axis Machining

Linkage control and multi-axis machining are essential for meeting the demanding requirements of modern manufacturing. In industries such as aerospace and medical, parts often have complex geometries and tight tolerances. These requirements can only be met by using advanced CNC machining techniques such as linkage control and multi-axis machining.

Moreover, linkage control and multi-axis machining can help manufacturers reduce costs by improving production efficiency and reducing waste. By machining parts in a single setup, manufacturers can save time and money on tool changes, setups, and inspections. Additionally, the ability to machine complex geometries can reduce the need for secondary operations, further reducing costs.

V. The Challenges of Linkage Control and Multi-Axis Machining

While linkage control and multi-axis machining offer many benefits, they also present some challenges. One of the main challenges is programming and setup. Multi-axis machining requires complex programming and setup procedures, which can be time-consuming and require specialized skills. Additionally, the increased number of axes can make it more difficult to optimize cutting parameters and ensure stable machining.

Another challenge is tooling. Multi-axis machining often requires specialized cutting tools that are designed to handle the complex geometries and high cutting forces involved. These tools can be expensive and may require frequent replacement, adding to the cost of production.

VI. Overcoming the Challenges

To overcome the challenges of linkage control and multi-axis machining, manufacturers can take several steps. First, they can invest in advanced programming software and training for their operators. This can help simplify the programming and setup process and ensure that the machine is used to its full potential.

Second, manufacturers can work with tooling suppliers to develop specialized cutting tools that are optimized for multi-axis machining. These tools can improve cutting efficiency, reduce tool wear, and lower production costs.

Finally, manufacturers can collaborate with experienced CNC machining service providers like Rapidefficient. Rapidefficient specializes in CNC aluminum machining and has extensive experience in linkage control and multi-axis machining. Their team of experts can help manufacturers overcome the challenges of these advanced machining techniques and achieve their production goals.

VII. The Value of Rapidefficient in the CNC Machining Market

Rapidefficient stands out in the CNC machining market for several reasons. First, they have a state-of-the-art facility equipped with the latest CNC machine tools and technology. This allows them to handle a wide range of machining projects, from simple parts to complex geometries.

Second, Rapidefficient has a team of highly skilled and experienced machinists and engineers. They are dedicated to providing high-quality machining services and ensuring that every project meets the highest standards of precision and quality.

Third, Rapidefficient offers competitive pricing and fast turnaround times. They understand the importance of meeting deadlines and delivering projects on time and within budget.

Finally, Rapidefficient is committed to customer satisfaction. They work closely with their customers to understand their needs and provide customized solutions that meet their specific requirements.

VIII. Conclusion

Linkage control and multi-axis machining are powerful techniques that can significantly improve the efficiency and precision of CNC machining. While they present some challenges, these challenges can be overcome with the right tools, training, and expertise. By working with a trusted CNC machining service provider like Rapidefficient, manufacturers can take advantage of these advanced techniques and achieve their production goals.

If you’re looking for a reliable and experienced CNC aluminum machining service provider, look no further than Rapidefficient. Contact them today to learn more about their services and how they can help you with your next machining project.