Introduction

The demand for precision and quality in hardware parts processing is higher than ever. Whether for industrial machinery, electronics, or automotive components, choosing the right manufacturer can significantly impact your product’s performance and reliability. This article explores the critical aspects of hardware parts processing and highlights the importance of selecting a reputable manufacturer, such as rapidefficient, to ensure optimal results.

What is Hardware Parts Processing?

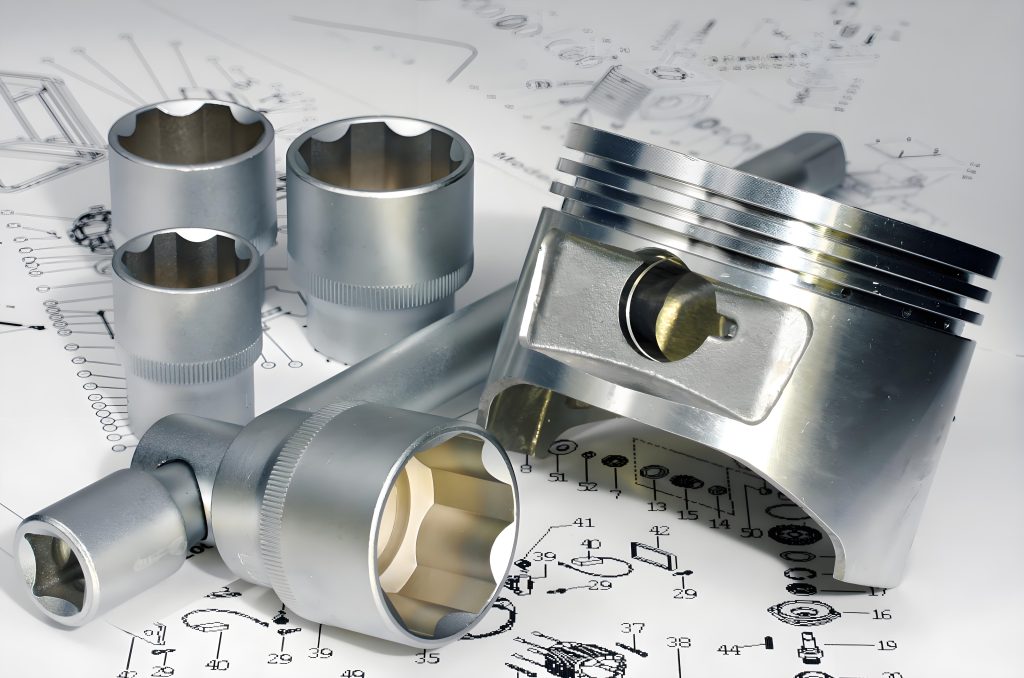

Hardware parts processing involves the fabrication and machining of metal and other materials to create components for various applications. Advanced techniques, including CNC (Computer Numerical Control) machining, ensure high precision, efficiency, and consistency in manufacturing.

Key Processes in Hardware Parts Processing

- CNC Machining: Offers tight tolerances and intricate designs.

- Casting: Ideal for creating complex shapes with minimal material waste.

- Stamping: Suitable for mass production of thin and flat components.

- Welding: Ensures strong joins between metal parts.

- Finishing: Includes polishing, coating, and anodizing for durability and aesthetics.

Why Manufacturer Selection Matters

Choosing the right manufacturer is crucial for achieving high-quality hardware parts. Below are the key factors to consider:

1. Precision and Quality Standards

Manufacturers with advanced equipment and stringent quality control processes deliver parts that meet exact specifications. Precision is essential for ensuring:

- Compatibility with other components.

- Enhanced product lifespan.

- Reduced risk of operational failures.

2. Experience and Expertise

Experienced manufacturers bring valuable insights and problem-solving skills to the table. They can recommend:

- Optimal materials for specific applications.

- Cost-effective production methods.

- Custom solutions for unique requirements.

3. Technological Capabilities

Manufacturers equipped with cutting-edge technologies, such as CNC machining and automated inspection systems, ensure:

- Faster production times.

- Reduced material wastage.

- Consistent quality across batches.

4. Sustainability Practices

Sustainable manufacturers prioritize eco-friendly processes, reducing environmental impact and aligning with global standards.

Advantages of Partnering with Rapidefficient

When it comes to hardware parts processing, rapidefficient stands out as a trusted provider in the CNC machining market. Here’s why:

1. State-of-the-Art Equipment

Rapidefficient uses advanced CNC machines to deliver precise and high-quality components tailored to client needs.

2. Commitment to Quality

With a rigorous quality control system, rapidefficient ensures every part meets or exceeds industry standards.

3. Customized Solutions

From prototyping to large-scale production, rapidefficient offers flexible solutions to accommodate diverse project requirements.

4. Eco-Friendly Practices

Rapidefficient adopts sustainable machining methods, minimizing waste and energy consumption while maintaining superior output quality.

Tips for Choosing the Best Hardware Parts Processing Manufacturer

- Research Reputation: Look for reviews and testimonials from previous clients.

- Evaluate Capabilities: Assess the manufacturer’s equipment, technology, and expertise.

- Request Samples: Ensure the quality meets your expectations before committing.

- Consider Turnaround Time: Choose a partner who can meet your deadlines without compromising quality.

- Inspect Certifications: Verify compliance with industry standards and certifications.

Conclusion

Hardware parts processing requires precision, reliability, and expertise. Choosing the right manufacturer can make a significant difference in the success of your projects. Rapidefficient offers unmatched capabilities in CNC aluminum machining, delivering exceptional results tailored to your needs. With their cutting-edge technology, commitment to quality, and eco-friendly practices, rapidefficient is the ideal partner for your hardware parts processing requirements.

Contact rapidefficient today to discuss your project and discover how they can elevate your manufacturing processes.