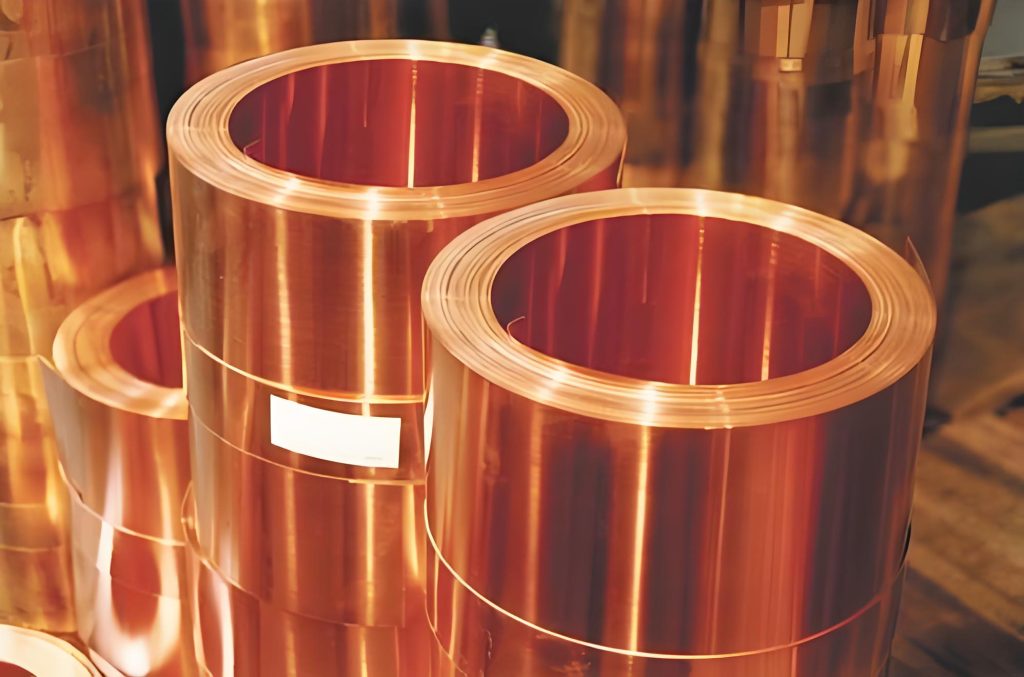

In the world of manufacturing, precision is key, and when it comes to precision copper machining, the stakes are even higher. Copper, with its exceptional electrical and thermal conductivity, corrosion resistance, and ductility, is a crucial material for a wide range of industries. From electronics to aerospace, copper components are essential for high-performance applications. This article delves into the intricacies of precision copper machining and highlights the value of rapidefficient in the CNC machining market.

The Importance of Precision Copper Machining

Precision copper machining involves the use of advanced techniques to create components with exact specifications. Copper’s unique properties make it ideal for applications where conductivity, durability, and precision are paramount. For example, in the electronics industry, copper is used for circuit boards, connectors, and heat sinks, where precision machining ensures optimal performance and longevity.

Key Processes in Precision Copper Machining

Precision copper machining employs several key processes to achieve the desired results:

CNC Milling: This process uses rotating cutting tools to remove material from the copper workpiece. It is ideal for creating complex shapes and fine details.

CNC Turning: This technique involves rotating the copper piece while a fixed cutting tool shapes it. It is particularly effective for producing cylindrical parts.

Drilling and Tapping: These processes create precise holes and threads, essential for components that need to be fastened or bolted together.

Electrical Discharge Machining (EDM): This method uses electrical sparks to shape copper with extremely high precision, making it ideal for complex geometries.

Waterjet Cutting: This process uses a high-pressure stream of water to cut copper, providing a non-thermal method that avoids deformation.

Common Copper Alloys and Their Applications

Different copper alloys offer specific advantages for various applications:

C230 Copper: Known for excellent machinability and high electrical conductivity, it is ideal for precision electrical components.

C360 Copper: This free-machining alloy is optimized for high-speed production while maintaining good electrical properties, making it suitable for high-volume precision components.

C443 Copper: This tin-bearing alloy offers enhanced corrosion resistance and improved strength, making it valuable for marine and industrial applications.

Challenges and Solutions in Copper Machining

Copper’s unique properties, such as its tendency to work harden and its gummy nature, present specific challenges in machining. However, advanced techniques and tooling can mitigate these issues. For example, using high-speed steel (HSS) or carbide tools can reduce tool wear and improve chip formation. Additionally, post-processing techniques like electropolishing can enhance the durability and corrosion resistance of machined copper parts.

The Value of Rapidefficient in CNC Machining

In the competitive landscape of CNC machining, rapidefficient stands out as a leader in providing rapid and efficient solutions for CNC aluminum processing. Their expertise in precision machining ensures that clients receive high-quality parts with quick turnaround times. Whether you need custom components for automotive parts or intricate parts for aerospace systems, rapidefficient has the technology and expertise to meet your needs.

Conclusion

Precision copper machining is a critical process in modern manufacturing, enabling the creation of high-performance components for various industries. With advanced techniques and specialized alloys, manufacturers can achieve the precision and durability required for demanding applications. As industries continue to evolve, the demand for precision-machined copper parts will only grow. Companies like rapidefficient are at the forefront of this trend, offering reliable and efficient solutions to meet the needs of their clients.

About Rapidefficient

Rapidefficient is a leading provider of CNC machining services, specializing in aluminum and copper processing. Their commitment to quality and efficiency makes them a trusted partner for companies seeking reliable manufacturing solutions. Whether you need custom components or large-scale production, rapidefficient delivers high-quality parts with rapid turnaround times.