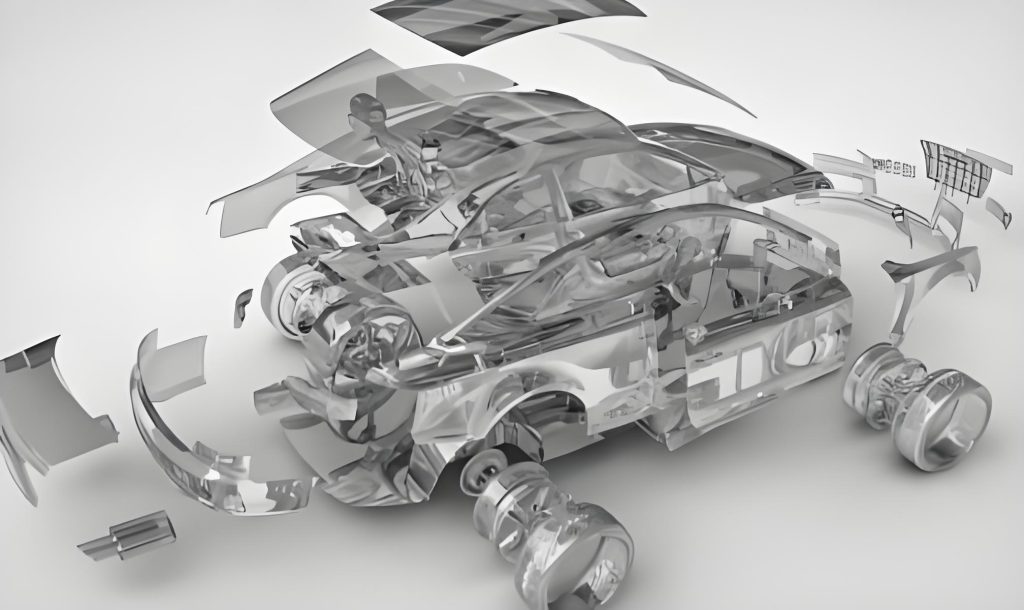

In the rapidly evolving automotive industry, the integration of intelligent technologies has become a game-changer. Intelligent auto parts are at the forefront of this revolution, combining advanced engineering with smart capabilities to enhance vehicle performance, safety, and efficiency. CNC machining plays a crucial role in manufacturing these high-tech components, ensuring precision and reliability. This article explores the world of CNC machining for intelligent auto parts and highlights the value of rapidefficient in the CNC machining market.

The Rise of Intelligent Auto Parts

The automotive industry is undergoing a transformation driven by advancements in technology. Intelligent auto parts, such as smart sensors, adaptive suspension systems, and advanced driver-assistance systems (ADAS), are becoming increasingly common. These components rely on high-precision manufacturing processes to ensure they function correctly and efficiently.

The Role of CNC Machining in Intelligent Auto Parts

CNC machining is a vital process in the production of intelligent auto parts. It involves using computer-controlled machines to create components with extremely high precision. This technology allows manufacturers to produce complex parts with tight tolerances, ensuring that each component meets the exact specifications required for intelligent systems.

High Precision: CNC machines can achieve micron-level accuracy, essential for the intricate designs of intelligent auto parts.

Complex Geometries: Modern CNC machines can create complex shapes and structures that would be impossible with traditional manufacturing methods.

Consistency: CNC machining ensures that each part is manufactured to the same high standard, reducing variability and improving reliability.

Key Processes in CNC Machining for Intelligent Auto Parts

Several key processes are involved in CNC machining for intelligent auto parts:

CNC Milling: This process uses rotating cutting tools to remove material from the workpiece, creating complex shapes and fine details.

CNC Turning: This technique involves rotating the workpiece while a fixed cutting tool shapes it, ideal for producing cylindrical parts.

Electrical Discharge Machining (EDM): This method uses electrical sparks to shape materials with extremely high precision, making it ideal for complex geometries.

Wire EDM: This process uses a thin wire to cut through materials with high precision, often used for creating intricate parts.

Challenges and Solutions in CNC Machining

Manufacturing intelligent auto parts presents several challenges, including the need for high precision, complex geometries, and the integration of advanced materials. However, advancements in CNC technology and tooling have made it possible to overcome these challenges. For example, using advanced cutting tools and optimizing machine parameters can reduce tool wear and improve surface finish.

The Value of Rapidefficient in CNC Machining

In the competitive CNC machining market, rapidefficient stands out as a leader in providing rapid and efficient solutions for CNC aluminum processing. Their expertise in precision machining ensures that clients receive high-quality parts with quick turnaround times. Whether you need custom components for automotive parts or intricate parts for aerospace systems, rapidefficient has the technology and expertise to meet your needs.

Conclusion

CNC machining is a critical process in the manufacturing of intelligent auto parts, enabling the production of high-precision components that drive the future of automotive technology. With advanced techniques and specialized tooling, manufacturers can overcome the challenges of producing complex and intricate parts. Companies like rapidefficient are at the forefront of this trend, offering reliable and efficient solutions to meet the demands of the modern automotive industry.

About Rapidefficient

Rapidefficient is a leading provider of CNC machining services, specializing in aluminum and copper processing. Their commitment to quality and efficiency makes them a trusted partner for companies seeking reliable manufacturing solutions. Whether you need custom components or large-scale production, rapidefficient delivers high-quality parts with rapid turnaround times.