1. Introduction

In the highly competitive landscape of modern manufacturing, Aluminum CNC prototyping has emerged as a cornerstone for innovation and product success. This article delves into the intricacies of Aluminum CNC prototyping, highlighting its significance, process, and the remarkable services offered by Rapidefficient.

2. The Significance of Aluminum in CNC Prototyping

Aluminum is a preferred material for CNC prototyping due to its unique combination of properties. It exhibits excellent strength-to-weight ratio, making it suitable for a wide range of applications where weight reduction is crucial without compromising on structural integrity. Its high thermal conductivity allows for efficient heat dissipation, which is vital in components that generate heat, such as electronic enclosures and heat exchangers. Additionally, aluminum is highly corrosion-resistant, ensuring the durability of the prototypes in various environmental conditions.

3. The Aluminum CNC Prototyping Process

3.1 Design Phase

The journey of an Aluminum CNC prototype begins with the design. Engineers and designers utilize advanced Computer-Aided Design (CAD) software to create a detailed 3D model of the desired prototype. This model serves as the blueprint for the entire prototyping process. It allows for precise visualization of the product’s geometry, dimensions, and features. The CAD model can be easily modified and optimized to meet specific design requirements and functional objectives.

3.2 Material Selection

Once the design is finalized, the appropriate aluminum alloy is chosen. Different aluminum alloys possess distinct mechanical, thermal, and chemical properties. For instance, 6061 aluminum is known for its good general-purpose characteristics, including moderate strength and excellent corrosion resistance. On the other hand, 7075 aluminum offers higher strength, making it suitable for applications that demand greater mechanical performance. The selection of the right alloy is crucial as it directly impacts the performance and quality of the prototype.

3.3 Machining Operations

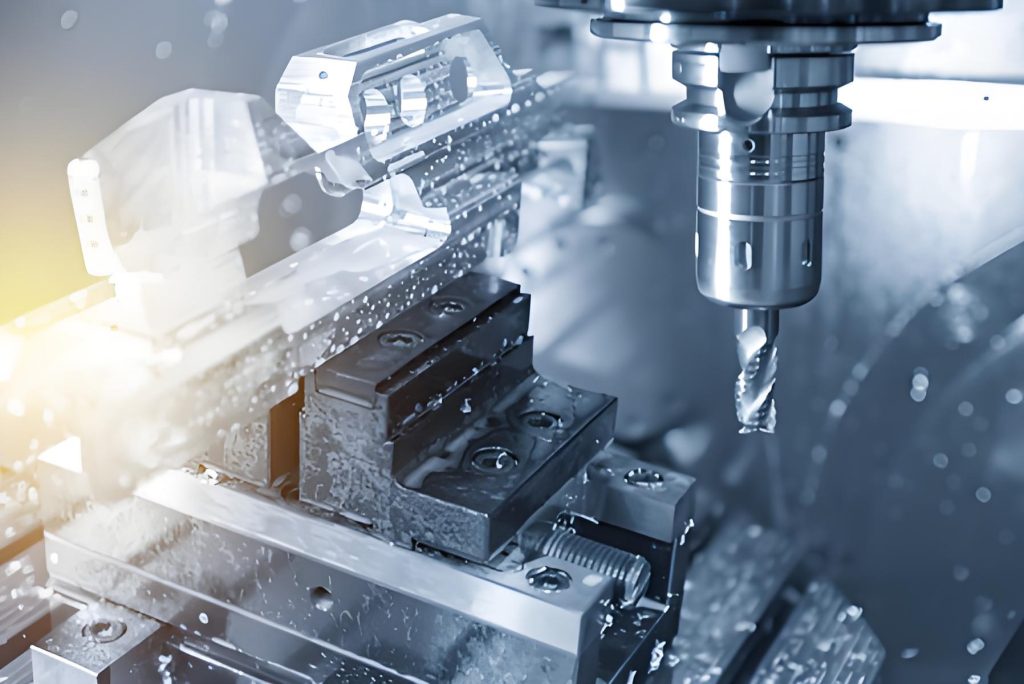

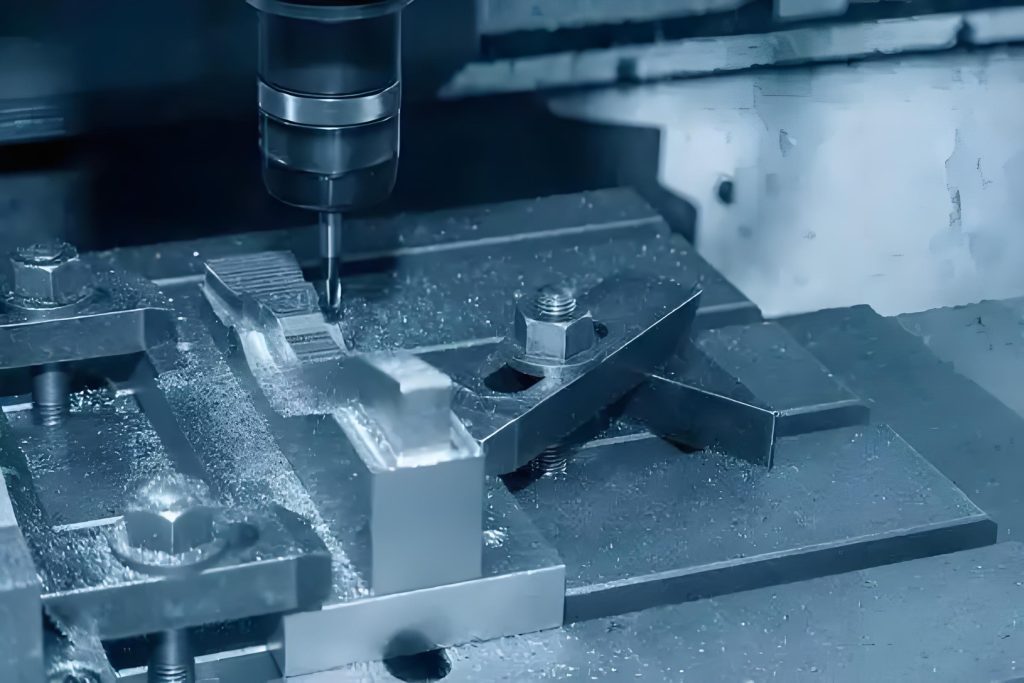

3.3.1 Milling

Milling is a fundamental operation in Aluminum CNC prototyping. It involves the use of rotating cutting tools to remove material from the aluminum workpiece. The CNC milling machine precisely controls the movement of the tool in multiple axes (usually three or five axes), enabling the creation of complex shapes, cavities, and contours. High-speed milling techniques are often employed to achieve efficient material removal and excellent surface finishes. Rapidefficient utilizes state-of-the-art milling machines that can handle a wide range of aluminum alloys and produce prototypes with tight tolerances.

3.3.2 Turning

Turning is another essential process, particularly for cylindrical or rotational parts. The aluminum workpiece is rotated while a stationary cutting tool is used to shape the outer diameter, inner diameter, or faces of the part. CNC turning machines at Rapidefficient are equipped with advanced tooling and control systems, allowing for high-precision turning operations. This enables the production of smooth and accurate cylindrical prototypes, such as shafts, bushings, and connectors.

3.3.3 Drilling and Tapping

Drilling is used to create holes in the aluminum prototype, and tapping is the process of creating internal threads. These operations require precise control of the drill or tap’s position, depth, and speed. Rapidefficient’s CNC machines ensure accurate hole placement and thread quality, which is essential for the proper assembly and functionality of the prototype.

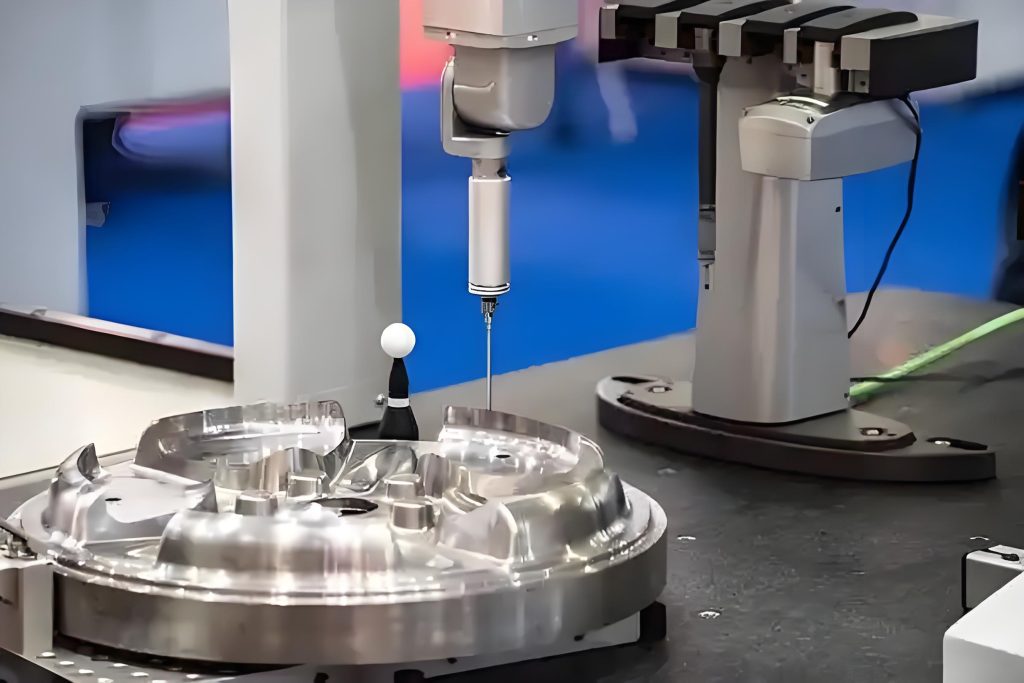

3.4 Quality Assurance

Quality control is an integral part of the Aluminum CNC prototyping process. Rapidefficient employs a comprehensive quality assurance system that includes in-process inspections and final inspections. Advanced metrology tools such as coordinate measuring machines (CMMs) are used to measure the dimensions and geometries of the prototypes and compare them with the design specifications. Any deviations are detected and corrected promptly to ensure that the prototypes meet the highest quality standards. Surface finish inspections are also carried out to assess the smoothness and appearance of the parts, as a good surface finish is often required for both functional and aesthetic reasons.

4. Advantages of Aluminum CNC Prototyping

4.1 Rapid Iteration

Aluminum CNC prototyping allows for quick design iterations. With the ability to make changes to the CAD model and have the updated prototype machined in a relatively short time, manufacturers can test and refine their designs more efficiently. This accelerates the product development cycle and reduces the time to market, giving companies a competitive edge.

4.2 Design Freedom

The precision and flexibility of CNC machining enable the creation of highly complex and customized prototypes. Designers are not limited by the constraints of traditional manufacturing methods and can explore innovative geometries and features. This freedom of design leads to more unique and functional products that can better meet the specific needs of customers.

4.3 Cost-Effectiveness in the Long Run

While the initial cost of Aluminum CNC prototyping may seem higher compared to some other prototyping methods, it offers significant cost savings in the long term. The accurate prototypes produced can be used for more reliable testing and validation, reducing the risk of costly design errors in the production phase. Additionally, the ability to make small production runs of the final product using the same CNC machining process can be more economical than setting up large-scale production lines for products with uncertain market demand.

5. Rapidefficient’s CNC Machining Services for Aluminum Prototyping

5.1 High-Speed Machining Capabilities

Rapidefficient specializes in high-speed machining of aluminum prototypes. Their advanced CNC machines are capable of achieving high spindle speeds and rapid feed rates, which significantly reduce the machining time. This not only speeds up the prototyping process but also helps in maintaining the integrity of the aluminum material by minimizing heat generation during cutting. The result is prototypes with excellent surface finishes and dimensional accuracy.

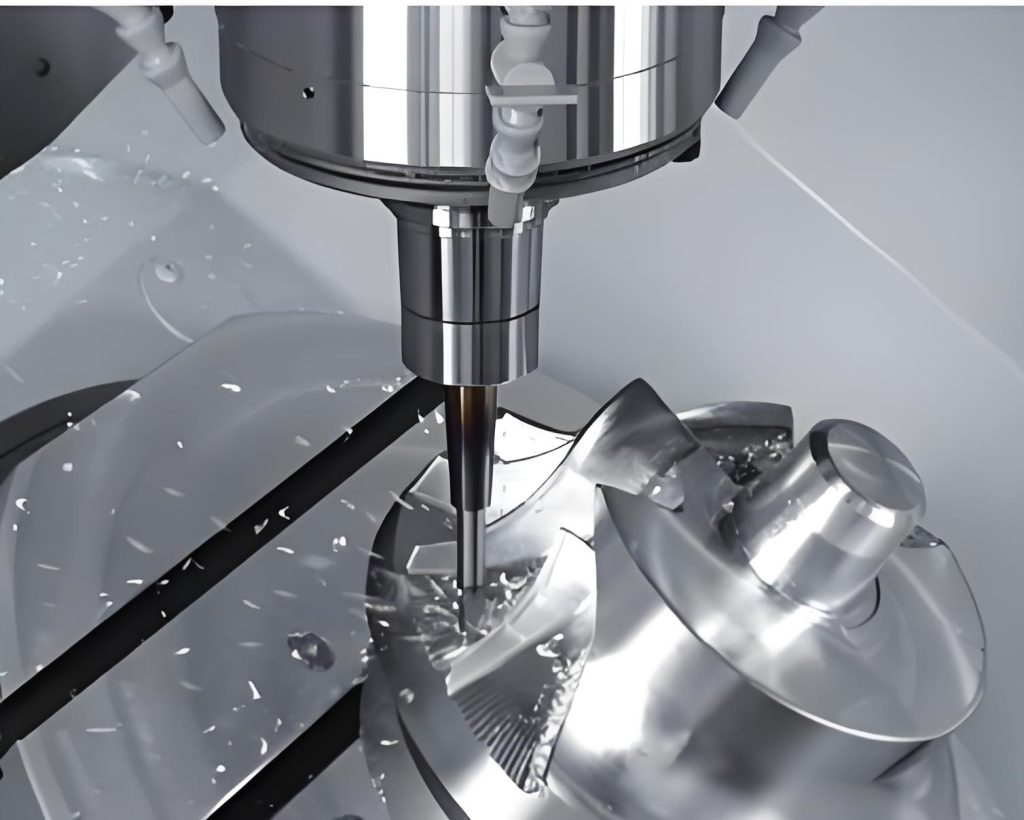

5.2 Multi-Axis Machining Expertise

The company has extensive experience in multi-axis CNC machining. With five-axis machining capabilities, Rapidefficient can produce prototypes with extremely complex geometries in a single setup. This eliminates the need for multiple setups and reduces the chances of errors and inaccuracies that can occur during part repositioning. The multi-axis machining also enables the creation of undercuts, angled surfaces, and other intricate features that are difficult to achieve with traditional three-axis machining.

5.3 Prototype Customization and Optimization

Rapidefficient offers comprehensive customization services for aluminum prototypes. Their team of engineers works closely with clients to understand their specific requirements and design goals. They provide valuable input and suggestions for optimizing the design for manufacturability, ensuring that the prototypes not only meet the functional requirements but are also cost-effective and easy to produce. Whether it’s a simple concept prototype or a highly complex functional prototype, Rapidefficient can tailor the machining process to deliver the best results.

5.4 Quality and Certification

Rapidefficient is committed to delivering the highest quality aluminum prototypes. They adhere to strict quality control standards and have obtained relevant certifications in the manufacturing industry. Their quality management system ensures that every prototype is manufactured and inspected with the utmost care and precision. This gives clients the confidence that they are receiving reliable and accurate prototypes that meet or exceed industry standards.

6. Case Studies of Rapidefficient’s Aluminum CNC Prototyping Success

6.1 Automotive Component Prototype

Rapidefficient was commissioned to produce a prototype of an aluminum automotive component. The design required complex internal channels for fluid flow and tight tolerances for proper fitment within the vehicle’s engine system. Using their multi-axis CNC machining expertise and high-speed milling capabilities, Rapidefficient was able to manufacture the prototype with exceptional accuracy. The prototype was tested and validated, and the design was subsequently refined based on the test results. The final production version of the component was then successfully implemented in the automotive manufacturing process, improving the performance and efficiency of the vehicle.

6.2 Consumer Electronics Enclosure Prototype

A leading consumer electronics company approached Rapidefficient for a prototype of an aluminum enclosure for a new handheld device. The enclosure needed to have a sleek and modern design with precise cutouts for buttons, ports, and a display. Rapidefficient’s customization and optimization services came into play. They worked with the client to refine the design, suggesting changes to enhance the manufacturability and overall aesthetics. Through careful CNC machining, they produced a prototype with a flawless surface finish and accurate dimensions. The prototype was well-received by the client, and it served as the basis for the mass production of the enclosures, which contributed to the successful launch of the new consumer electronics product.

7. Why Choose Rapidefficient for Aluminum CNC Prototyping

7.1 Technical Expertise and Experience

Rapidefficient has a team of highly skilled engineers and machinists with extensive experience in Aluminum CNC prototyping. Their technical knowledge and hands-on skills enable them to handle even the most challenging prototyping projects with ease. They stay updated with the latest advancements in CNC machining technology and apply them to deliver superior results.

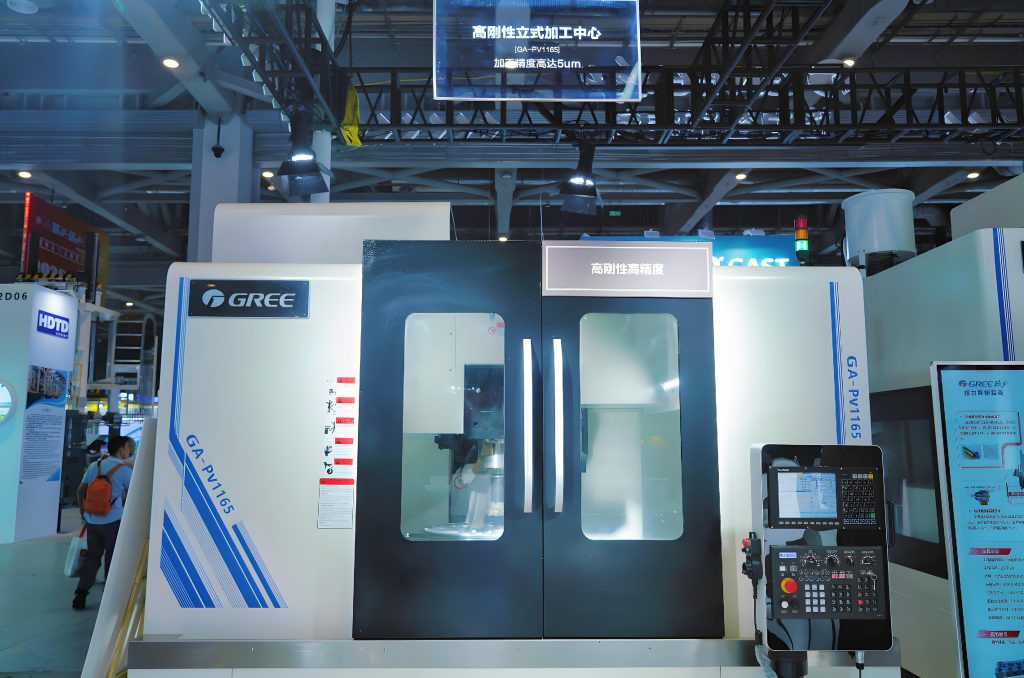

7.2 State-of-the-Art Equipment

The company invests in state-of-the-art CNC machines and metrology equipment. Their machining centers are equipped with advanced features such as high-speed spindles, automatic tool changers, and precision motion control systems. The metrology tools ensure accurate measurement and quality control, allowing for the production of prototypes with the tightest tolerances.

7.3 Timely Delivery and Customer Support

Rapidefficient understands the importance of timely delivery in the product development process. They have efficient project management systems in place to ensure that prototypes are completed and delivered on schedule. Their customer support team is always available to answer client questions, provide project updates, and address any concerns or issues that may arise during the prototyping process.

7.4 Competitive Pricing

Despite offering top-notch services and high-quality prototypes, Rapidefficient provides competitive pricing. They offer cost-effective solutions that fit within the budget constraints of different clients, from startups to large enterprises. Their transparent pricing model and value-added services make them an attractive choice for Aluminum CNC prototyping.

8. Conclusion

Aluminum CNC prototyping is a powerful tool in the modern manufacturing arsenal, enabling rapid innovation and product development. Rapidefficient stands out as a premier provider of CNC machining services for aluminum prototyping, with its advanced capabilities, technical expertise, and commitment to quality and customer satisfaction. Whether you are developing a new product in the automotive, aerospace, consumer electronics, or any other industry, choosing Rapidefficient for your Aluminum CNC prototyping needs can give you a significant advantage in bringing your ideas to life and succeeding in the market.