Sheet metal processing is a crucial process used across a variety of industries. Its versatility, precision, and durability make it suitable for creating a wide range of products. From construction to electronics, sheet metal plays a vital role in modern manufacturing. In this article, we’ll explore the major applications of sheet metal fabrication and why it is so essential.

Automotive Industry

The automotive industry relies heavily on sheet metal processing. Manufacturers use sheet metal to produce car bodies, engine components, and various structural parts. Steel and aluminum are the most commonly used metals in this industry due to their strength and light weight. These properties help improve vehicle performance and fuel efficiency.

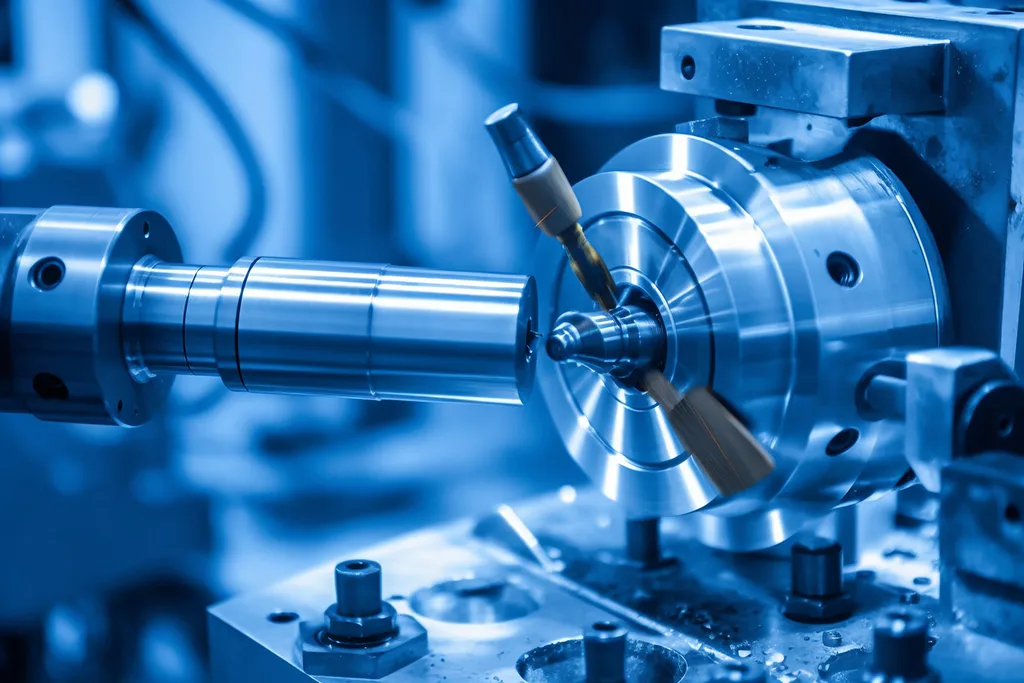

Additionally, the precision that sheet metal processing offers is vital for creating high-quality automotive parts. Laser cutting and CNC machines ensure that each part fits perfectly. This reduces errors and enhances the overall quality of the vehicle. Moreover, manufacturers can produce these parts at scale, making sheet metal processing cost-effective for mass production.

Aerospace Industry

In aerospace, precision is everything. Sheet metal processing is crucial for producing aircraft components that meet strict safety and performance standards. Aluminum and titanium are often used because of their lightweight and high-strength properties. These metals are ideal for aircraft bodies, wings, and other critical parts.

Fabricators use advanced techniques like laser cutting and bending to shape the metal into complex forms. These methods help create parts that can withstand extreme conditions, including high temperatures and pressure. The durability and accuracy of sheet metal processing ensure that airplanes and spacecraft operate safely and efficiently.

Electronics Industry

The electronics industry also benefits greatly from sheet metal processing. Manufacturers use sheet metal to create enclosures, frames, and housing for electronic devices. These metal parts protect delicate internal components from damage, heat, and electromagnetic interference.

Precision is key in this industry as well. Sheet metal processing allows for the creation of small, intricate parts that fit perfectly within electronic devices. Laser cutting and CNC machining ensure that every part is made to exact specifications. This level of precision is essential for producing high-quality electronics like smartphones, computers, and medical devices.

Construction Industry

Sheet metal is widely used in the construction industry for both structural and functional purposes. In particular, it is commonly found in roofing, HVAC systems, gutters, and siding. Steel and aluminum are popular choices because they are durable, weather-resistant, and easy to work with.

Moreover, sheet metal processing allows for customized solutions. Construction projects often require materials in specific shapes and sizes, and sheet metal can be cut and bent to meet these needs. This flexibility makes sheet metal essential in building projects where precision and durability are critical.

Medical Equipment Manufacturing

The medical industry requires equipment that meets high standards of cleanliness, durability, and precision. Sheet metal processing plays a key role in producing medical devices and equipment such as surgical instruments, hospital beds, and diagnostic machines.

Stainless steel is often used in this field due to its resistance to corrosion and ease of sterilization. Fabricators can shape sheet metal into complex designs, ensuring that medical equipment functions properly and safely. The ability to quickly produce custom parts is also a significant advantage, especially for specialized medical tools and devices.

Agriculture Industry

In the agriculture sector, sheet metal processing is essential for creating equipment and machinery that withstands harsh outdoor conditions. Tractors, plows, and storage silos often use sheet metal components due to their strength and resistance to rust. These parts need to endure exposure to the elements while maintaining functionality.

Sheet metal’s flexibility allows manufacturers to produce agricultural machinery in various sizes and designs. This adaptability is important for farmers who rely on custom-built equipment tailored to their specific needs.

Consumer Products

Sheet metal processing is also prevalent in the manufacturing of consumer products. Household appliances like refrigerators, ovens, and washing machines all use sheet metal for their structural components. Stainless steel, in particular, is favored for its durability and clean appearance.

Manufacturers benefit from the precision and efficiency of sheet metal processing. Laser cutting and CNC machining ensure that parts are produced quickly and accurately, reducing production times and costs. This allows for large-scale production of consumer goods without compromising on quality.

Conclusion

In conclusion, sheet metal processing has a broad range of applications across many industries. Its versatility, durability, and precision make it indispensable for manufacturing everything from cars and airplanes to medical devices and consumer products. Whether in automotive, aerospace, electronics, or construction, sheet metal processing provides the flexibility and reliability needed to produce high-quality parts efficiently. As technology continues to advance, sheet metal processing will remain a crucial process in modern manufacturing.