Exploring CNC Aluminum Parts: Lightweight Engineering for Every Industry

In modern industrial manufacturing, CNC aluminum parts machining plays an indispensable role. With its characteristics of high precision and efficiency, CNC...

The Lifeblood of Part Machining and Manufacturing: Precision, and the Crucial “Trace”

In the world of parts processing and manufacturing, CNC machining precision is paramount. Precision is not only a technical indicator,...

The Art of Material Selection in CNC Machining: The Perfect Balance of Performance, Cost, and Application

In the realm of precision manufacturing, CNC machining services have become a cornerstone of modern industries with their exceptional precision,...

What Are the Testing Methods for the Spindle Performance of a CNC Machining Center?

Introduction:The spindle is the heart of any CNC machining center — it directly determines machining precision, cutting stability, and surface...

What to Do If the Dividing Head Doesn’t Lock Properly During CNC Milling

The dividing head is an important accessory for CNC milling machines. It is generally used to mount workpieces for milling...

Analysis and Solutions for Tool Glitching in CNC Machining Centers

Introduction:In CNC machining centers, tool changing is one of the most frequent and critical operations in production. When a tool...

CNC Communication Parts Machining: Precision Manufacturing Forges the Cornerstone of the Information Age

In the wave of the Internet of Everything, from the core of high-speed 5G base stations to the smartphones in...

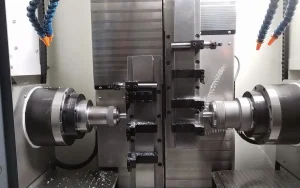

The Pulse of Smart Factories: How Automation Technology is Reshaping a New Era of CNC Machining

In a traditional CNC shop, the operator repeats the process day after day: lifting the heavy blank onto the table,...

CNC Machining: The Cornerstone of Precision in Aerospace Dreams

In the journey of human beings to explore the vast universe, every rocket liftoff and every plane soar are inseparable...

CNC machining: the precision backbone behind the new energy industry

When solar panels shine in the sun, when electric vehicles glide silently through the streets, and when giant wind turbine...

CNC Auto Parts Machining: The precision engine driving the future of automobile manufacturing

Imagine a high-speed car suddenly spiraling out of control due to a tiny dimensional deviation in a critical steering component;...

Solution for CNC Machining Center X-Axis Motor Overheat Alarm

Problem Symptom:The X-axis motor has overheated. Analysis and Solution:A motor overheat alarm can occur for a variety of reasons. Besides...

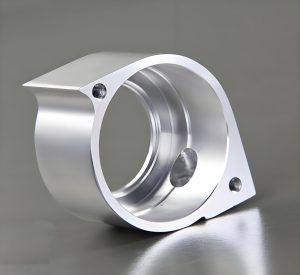

Complex Part Machining Services Where Precision Meets Complexity

Introduction In the world of manufacturing, complex part mechanical machining is a crucial process. It enables the creation of highly precise,...

Achieve High Precision with Expert Mechanical Machining Solutions

Introduction High precision mechanical machining solutions are essential for modern industries where exactness and performance are paramount. From aerospace to...

Discover Custom CNC Mechanical Machining Services Tailored to Your Needs

Introduction In the competitive world of manufacturing, precision is crucial. Custom CNC mechanical machining services have become essential for...

What are the steps of CNC machining?

In today’s era of rapid technological development, CNC machining has become an indispensable part of the manufacturing industry. It not...

Aluminum CNC Prototyping: Revolutionizing Product Development with Rapidefficient

1. Introduction In the highly competitive landscape of modern manufacturing, Aluminum CNC prototyping has emerged as a cornerstone for innovation...

Unleashing the Power of CNC Aluminum Parts Manufacturing with Rapidefficient

1、Introduction In today’s rapidly evolving industrial landscape, CNC aluminum parts manufacturing plays a crucial role. This article aims to provide...

CNC Aluminum Machining Services: Unleashing Precision and Efficiency

Introduction Overview of CNC Aluminum Machining CNC aluminum machining is a highly sophisticated and essential process in various industries. This...

High-Precision Aluminum CNC Machining: A Comprehensive Overview

1、Introduction to High-Precision Aluminum CNC Machining High-precision aluminum CNC machining is a crucial process in modern manufacturing. It involves the...

The Advantages and Applications of CNC Aluminum Machining in Modern Manufacturing

ABSTRACT This paper discusses the importance of CNC aluminum machining in modern manufacturing. It elaborates on the research background and...

Aerospace-Grade Aluminum Machining: Precision in the Skies

1、Understanding Aerospace-Grade Aluminum Machining Aerospace-grade aluminum machining plays a crucial role in the aerospace industry. Aerospace-grade aluminum is a specialized...

CNC Aluminum Machining Tolerances

ABSTRACT This paper provides a comprehensive analysis of CNC aluminum machining tolerances. Key factors determining these tolerances are identified, including...

CNC Aluminum Machining: Unleashing Precision and Efficiency

I. Core Perspectives 1.1 Key Processes Driving Transformations in Manufacturing CNC Aluminum Processing: A Vital Technology in Modern Manufacturing CNC...

CNC Aluminum Prototype Machining: Unleashing Precision and Innovation

一、Understanding CNC Aluminum Prototype Machining (一)What is CNC Aluminum Prototype Machining? CNC aluminum prototype machining refers to the process of...

Research Report on Aerospace CNC Aluminum Machining

1. Core Viewpoints 1.1 Key Manufacturing Technology Driving Aerospace Development Aerospace CNC aluminum machining is of crucial significance in the...

Affordable Mechanical Machining Services Without Compromising Quality

Introduction In today’s manufacturing world, finding affordable mechanical machining services that also deliver quality and reliability is crucial. Businesses across...