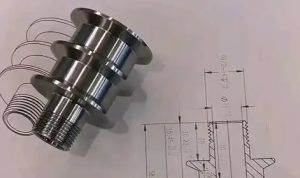

What are the main considerations for the geometric angles of CNC turning and milling?

When turning slender shafts, due to the poor rigidity of the workpiece, the shapes of the turning tool have a...

Key Measures for Ensuring Dimensional Accuracy in CNC Machined Precision Parts

The dimensional accuracy of precision parts directly impacts product quality and performance. Achieving high-precision machining requires a systematic approach, including...

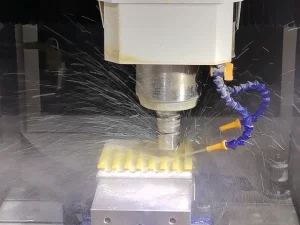

How to improve and solve the poor surface accuracy of CNC machining?

In CNC machining, surface accuracy is one of the most critical indicators of part quality, directly affecting assembly precision, wear...

Why is the material selection important for CNC turning and milling?

In CNC turning-milling, material selection directly impacts machining efficiency, part accuracy, surface quality, and final performance. Its importance lies in...

Analysis of Troubleshooting Handwheel Failures During CNC Machining

CNC machining is widely used across industries and manufacturers. During the manufacturing process, unexpected or human-caused failures are unavoidable, particularly...

Analysis of Causes of Oil Leakage in CNC Machining Centers

During CNC machining, unexpected issues often arise, but no matter what they are, they must be addressed promptly. Oil leaks...

What Problems Can Arise from Improperly Arranging CNC Machining Processes?

1. Excessively Fragmented CNC Machining Processes This problem arises from a fear of complexity (referring to setup time), a preference...

How to prevent common wear problems in part machining?

Common types of wear in part machining include: Run-in Wear Run-in wear is wear that occurs when a machine tool...

What factors should be considered when selecting cutting tools?

When selecting cutting tools, appropriate cutting tools and tool holders should be selected based on the function of the machining...

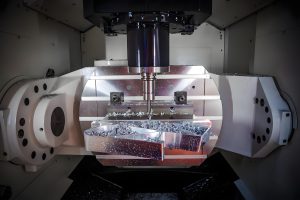

How can CNC 4-axis machining improve efficiency and quality?

In CNC 4-axis machining, improving efficiency and ensuring quality require a coordinated effort across multiple aspects, including process planning, programming...

What are the requirements of the CNC 4-Axis Machining Technical Standard?

CNC 4-axis machining refers to the fourth-axis rotary milling process on CNC machine tools. It adds a rotary axis (A-axis)...

Chatter Marks in CNC Machining and Solutions

Chatter marks in CNC machining are often caused by a variety of factors. Here are some possible solutions: CNC Machining...

Custom precision CNC machine tools for plastic automotive parts

Introduction In the automotive industry, plastic parts play a crucial role in modern vehicle manufacturing. They are used in various...

Can we provide customized parts processing service?

Introduction In the dynamic realm of modern manufacturing, the demand for precision and uniqueness has propelled customized parts processing services...

5 Ways to Improve the Accuracy of Precision Parts Processing

Introduction In the manufacturing industry, the accuracy of precision parts processing is of utmost importance. Precision parts are used in...

Theory of precision machining technology

In modern manufacturing, precision machining technology has emerged as a cornerstone, playing a pivotal role in elevating product quality, enhancing...

How to choose five – axis machine tool?

Introduction In the modern manufacturing landscape, the five – axis machine tool has emerged as a cornerstone of precision and...

Practice and optimization of CNC machining technology

I. Introduction In the modern manufacturing landscape, CNC machining technology stands as a cornerstone. It has revolutionized the way we...

How does die casting meet the needs of complex geometrics?

1. Introduction Die casting is a manufacturing process that has been around for centuries, but it continues to evolve and...

Precision CNC Machining Technology to Create High Quality Parts

Introduction In the modern manufacturing landscape, precision CNC machining technology stands as a cornerstone for creating high-quality parts. It has...

Production technology of NC machining parts in Chinese hardware industry is analyzed

I. Introduction In today’s highly developed manufacturing industry, the Chinese hardware industry plays a crucial role. As an important part...

Common Cold Processing in Machining: Unveiling Efficiency and Precision

I. Introduction Cold working in machining refers to the process of shaping and finishing metal components at or near room...

New Development of Cutting Technology for Difficult-to-Machine Materials

Introduction: The Significance of Advanced Cutting Technology In modern Machining material cutting technology, difficult-to-machine materials have found extensive applications across...

Advantages of hardware CNC lathe processing

I. Introduction In the modern manufacturing landscape, hardware CNC lathe processing stands as a cornerstone technology. It plays a pivotal...

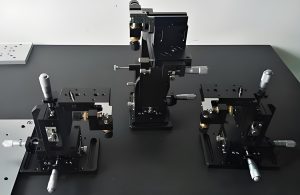

Optical communication parts CNC machining fast solution

I. Introduction In the digital age, optical communication has become the backbone of global connectivity. From high-speed internet access to...

Fast solution for CNC machining of semiconductor parts

I. Introduction In the highly competitive landscape of the electronics industry, semiconductor parts stand as the linchpin of technological advancement....

New energy parts CNC machining fast solution

I. Introduction In recent years, with the rapid development of new energy technologies, the demand for new energy parts has...

Fast solution for cnc machining medical parts

1. Introduction In recent years, the medical industry has witnessed remarkable growth, with a surging demand for sophisticated and precise...

Robot parts CNC machining fast solution

Ⅰ. Introduction In recent years, the field of robotics has witnessed remarkable advancements, revolutionizing industries across the globe. From automotive...

CNC Machining Technology of Thin-Walled Shell Parts with Easy Deformation: High-Speed Solutions

I. Introduction Thin-walled shell parts,with their lightweight and compact design, have become ubiquitous in various industries. From aerospace components that...

Application of high speed CNC machining in aircraft parts manufacturing

I. Introduction In the highly advanced realm of aircraft manufacturing, precision and efficiency are not just desirable traits but absolute...

Overview: Types of Springs and their applications

Springs: An Introduction Springs are ubiquitous mechanical components that play a crucial role in modern life. They are elastic objects...

Parts processing technology and flow

The Core of Parts Processing Technology What is Parts Processing Technology Parts processing technology is the cornerstone of modern manufacturing,...

CNC Machining of Aluminum Alloy Material

The Basics of Aluminum Alloy in CNC Machining What is Aluminum Alloy? Aluminum alloy is a material composed mainly of...

Three Factors Affecting the Machining Accuracy of CNC Milling Machine and Four Solutions

1、Introduction to CNC Milling Machine Machining Accuracy 1. Briefly introduce what CNC milling machine machining accuracy means and its importance...

CNC solutions from Rapidefficient suppliers

In the ever-evolving landscape of manufacturing, precision and efficiency are paramount. This is where CNC (Computer Numerical Control) solutions come...