Injection Molding Services: The precision manufacturing engine of modern manufacturing

Imagine the rugged case of your smartphone, the complex instrument cluster assembly inside a car, or the component in a...

The Art of Metal Bending: Efficient and Precise Solutions in Manufacturing Services

In the grand scheme of modern manufacturing, metal bending, a seemingly fundamental yet crucial process, acts like a low-key yet...

What factors influence CNC Swiss machining speed?

In modern manufacturing, CNC Swiss machining is an efficient, precise, and flexible process. It can be used to create products...

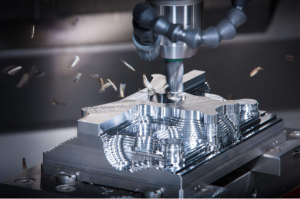

Essential Knowledge for CNC Machining of Precision Parts

We know that the emergence of CNC equipment is a significant milestone in technological advancement. It effectively addresses complex, precise,...

CNC Precision Parts Machining: Selection of Processing Methods and Division of Processes and Work Steps

In modern manufacturing, CNC precision parts machining requires not only high accuracy and excellent surface quality but also efficiency and...

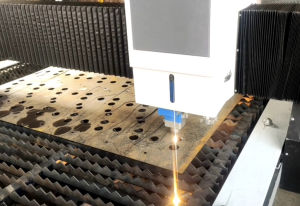

Laser Cutting: The Invisible Blade for Manufacturing Services Upgrades

In the early morning, when engineer Xiao Wang uploaded a complex stainless steel part design drawing to the cloud system...

A New Benchmark in Efficient Machining: CNC Turning and Rapidefficient’s Manufacturing Revolution

In the arena of manufacturing, time is cost, and precision is life. When traditional machining methods struggle to breathe in...

CNC Thread Machining Methods

Thread machining is one of the most commonly used operations in CNC machining. According to different machining methods, it can...

CNC Aluminum Machining: A Revolution in Efficiency and Precision in Precision Manufacturing

Aluminum, with its lightweight, high strength, corrosion resistance and excellent electrical and thermal conductivity, has become a core material in...

Types of CNC Machining Datums

To study the relative relationship of part surfaces, a datum must be determined. A datum is a point, line, or...

Choosing Methods for Machining Internal Holes and Surfaces of CNC Lathe Parts

There are numerous methods for machining the internal holes and surfaces of CNC lathe parts, including drilling, reaming, boring, turning,...

Six Processes That Can Easily Influence Machining Errors

The slightest carelessness during machine tool processing can lead to errors. Below are six processes that can easily cause machining...

How to charge for sleeve parts processing?

1、Introduction to Sleeve Parts Machining Sleeve parts machining is a crucial process in the manufacturing industry. It involves the shaping...

Cleaning methods and precautions for metal parts processing

1、Introduction to metal parts processing Metal parts processing is a crucial aspect of various industries, playing a significant role in...

CNC Milling Machine: Ideal for Processing Which Parts?

I. Introduction A. Briefly introduce CNC milling machines and their importance in manufacturing. CNC milling machines are highly significant in...

Machining Technology of Connecting Rod Parts

Introduction The Significance of Connecting Rod Parts Connecting rod parts play a crucial role in mechanical systems, especially in engines....

Wire-cut Machining: The Precision Power in CNC Realm

I. Introduction to Wire-cut Machining A. Definition and Basic Principle Wire-cut machining, also known as Wire Electrical Discharge Machining (WEDM),...

Aluminum alloy processing polishing mirror: dazzling surface treatment art

I. Introduction A. Hook the Readers In our daily life and various industries, aluminum alloy products with polished mirror surfaces...

Unveiling the Commonly Used Knives in CNC Machining

Introduction In the world of CNC machining, knives play an absolutely crucial role. They are like the “magic wands” that...

Analysis of bevel gear processing technology: Manufacturing art of precision transmission

Introduction:Bevel gear processing technology is crucial in precision transmission. This article explores its details and the value of rapidefficient in...

Application and Development Trend of CNC Milling Machine

I. Introduction to CNC Milling Machine A. Definition and Basic Functions A CNC milling machine, also known as a computer...

Aluminum alloy thin-wall parts processing how to anti-shock knife

I. Introduction The Significance of Aluminum Alloy Thin-Wall Parts Processing Aluminum alloy thin-wall parts play a crucial role in numerous...

What are the capacity indicators of aluminum alloy die-casting processing plants

1、Introduction What is aluminum alloy die-casting processing? Aluminum alloy die-casting processing is a manufacturing method that involves injecting molten aluminum...

Aluminum alloy precision die casting manufacturers how to choose?

1、Introduction 1. Definition and importance of these manufacturers in the industry. Aluminum alloy precision die casting manufacturers are specialized in...

How do we address the issue of poor after-sales service for parts?

The manufacturing industry is developing rapidly, and competition in the CNC machining industry is becoming increasingly fierce. Poor after-sales service...

Strategies for dealing with material changes and dimensional errors in CNC lathe machining

CNC lathe machining plays a vital role in modern manufacturing due to its high precision and efficiency. However, fluctuations in...

Strategies to improve CNC machining efficiency of non-standard parts

In the manufacturing industry, CNC machining of non-standard mechanical parts is a complex and delicate process. Improving the efficiency of...

CNC machining small batch and proofing efficiency improvement strategy: matching new product development progress

In the process of new product development, small-batch production and proofing of CNC machining often become key factors affecting the...

Optimize CNC machining delivery management: improve production planning efficiency and coordination

Frequent delays in CNC machining delivery not only affect the stability of production plans, but also increase the cost and...

Treatment and prevention strategies of defective products in CNC machining

In the field of CNC machining, the appearance of defective products not only affects production efficiency, but may also have...

How do we handle customer feedback and complaints?

In the CNC processing industry, customer feedback and complaints are important bases for companies to continuously improve and enhance service...

The most common defects and solutions for CNC machining of parts

CNC machining is a high-precision manufacturing technology, but it may also encounter some common machining defects. Understanding these defects and...

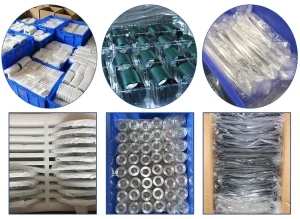

Packaging and Shipping Strategies for Safe Transportation of CNC Machined Parts

As a professional CNC processing factory, we know that every step from the product leaving the factory to the hands...

CNC Processing Plant for Collaborative Robot Parts

Collaborative robot parts are revolutionizing the manufacturing industry. These robots work alongside humans to enhance productivity and efficiency. At the...

Intelligent equipment parts CNC machining fast solution

1. Introduction In today’s highly developed manufacturing industry, intelligent equipment plays a crucial role in various fields. From industrial automation...

Marine equipment parts CNC machining fast solution

I. Introduction In recent years, the marine engineering industry has been booming, with the global demand for marine resources exploration,...