High-Hardness Materials CNC Machining Guide: Proven Techniques for Precision, Tool Life & Efficiency

Introduction In the CNC machining industry, one of the most common technical questions is how to maintain machining accuracy and...

Best Materials for CNC Machining Drone Parts: Top 5 Options for Strength, Weight & Performance

Introduction Material selection is one of the most critical decisions when manufacturing drone components using CNC machining. The right material...

Why CNC Machining Is the Best Choice for Precision Parts Manufacturing

Introduction In today’s competitive manufacturing environment, precision is no longer optional — it is essential. Industries such as aerospace, automotive,...

Flammability and Key Properties of Common Plastics Used in CNC Machining

When selecting plastic materials for CNC machining or prototype production, understanding how different plastics behave under heat and flame can...

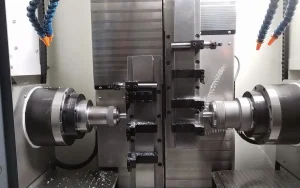

Three-Axis vs Four-Axis vs Five-Axis Machining Centers: Key Differences in Precision Manufacturing

In modern manufacturing, precision manufacturing machining centers are widely used for machining various parts due to their high precision, high...

Key Machinability Requirements for Precision Mechanical Parts Design

Precision mechanical parts, during the design process, must not only meet their functional requirements (i.e., possessing the necessary working capabilities)...

How to Properly Perform Tool Setting in CNC Machining?

Tool setting is a crucial step in CNC machining. Its purpose is to correctly align the tool and workpiece to...

Exploring CNC Aluminum Parts: Lightweight Engineering for Every Industry

In modern industrial manufacturing, CNC aluminum parts machining plays an indispensable role. With its characteristics of high precision and efficiency, CNC...

The Lifeblood of Part Machining and Manufacturing: Precision, and the Crucial “Trace”

In the world of parts processing and manufacturing, CNC machining precision is paramount. Precision is not only a technical indicator,...

The Art of Material Selection in CNC Machining: The Perfect Balance of Performance, Cost, and Application

In the realm of precision manufacturing, CNC machining services have become a cornerstone of modern industries with their exceptional precision,...

What Are the Testing Methods for the Spindle Performance of a CNC Machining Center?

Introduction:The spindle is the heart of any CNC machining center — it directly determines machining precision, cutting stability, and surface...

What to Do If the Dividing Head Doesn’t Lock Properly During CNC Milling

The dividing head is an important accessory for CNC milling machines. It is generally used to mount workpieces for milling...

Complex Part Machining Services Where Precision Meets Complexity

Introduction In the world of manufacturing, complex part mechanical machining is a crucial process. It enables the creation of highly precise,...

Achieve High Precision with Expert Mechanical Machining Solutions

Introduction High precision mechanical machining solutions are essential for modern industries where exactness and performance are paramount. From aerospace to...

Discover Custom CNC Mechanical Machining Services Tailored to Your Needs

Introduction In the competitive world of manufacturing, precision is crucial. Custom CNC mechanical machining services have become essential for...

What are the steps of CNC machining?

In today’s era of rapid technological development, CNC machining has become an indispensable part of the manufacturing industry. It not...

Precision Manufacturing, Protecting Lives: CNC Machining is the core solution in the field of medical devices

Under the shadowless light, the titanium alloy orthopedic implant in the surgeon’s hand is accurately fitting the patient’s bone; In...

Rapidefficient: Your expert in CNC machining service solutions

In the modern manufacturing battlefield that pursues efficiency and precision, the precision parts behind every product are the silent declaration...

The Duo of Speed and Precision: The Winning Way to Choose a CNC Machining Service Provider

In today’s rapid-paced manufacturing arena, “time is money” is no empty phrase. Production line shutdown due to delays in critical...

How Rapid Efficient Pushes CNC Machining Services to New Heights of Efficiency

In today’s competitive manufacturing landscape, precision and efficiency are the lifeblood of survival. Enterprises are not only looking for qualified...

How do we address the issue of poor after-sales service for parts?

The manufacturing industry is developing rapidly, and competition in the CNC machining industry is becoming increasingly fierce. Poor after-sales service...

Strategies for dealing with material changes and dimensional errors in CNC lathe machining

CNC lathe machining plays a vital role in modern manufacturing due to its high precision and efficiency. However, fluctuations in...

Strategies to improve CNC machining efficiency of non-standard parts

In the manufacturing industry, CNC machining of non-standard mechanical parts is a complex and delicate process. Improving the efficiency of...

CNC machining small batch and proofing efficiency improvement strategy: matching new product development progress

In the process of new product development, small-batch production and proofing of CNC machining often become key factors affecting the...

Optimize CNC machining delivery management: improve production planning efficiency and coordination

Frequent delays in CNC machining delivery not only affect the stability of production plans, but also increase the cost and...

Treatment and prevention strategies of defective products in CNC machining

In the field of CNC machining, the appearance of defective products not only affects production efficiency, but may also have...

How do we handle customer feedback and complaints?

In the CNC processing industry, customer feedback and complaints are important bases for companies to continuously improve and enhance service...

The most common defects and solutions for CNC machining of parts

CNC machining is a high-precision manufacturing technology, but it may also encounter some common machining defects. Understanding these defects and...