Precision Shaping Life: Innovative Breakthroughs and Core Values of CNC Machining Services in the Medical Device Field

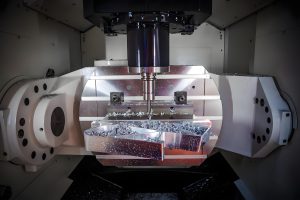

In the field of medical device manufacturing, which pursues ultimate precision and high reliability, a silent revolution led by advanced...

CNC Machining Services: The Cornerstone of Precision in Industrial Equipment Manufacturing

In the grand picture of industrial equipment manufacturing, precision, reliability, and efficiency are eternal themes. From the complex and precise...

CNC Machining: The “Invisible Champion” of Precision Manufacturing of Electronic Products

In today’s world where electronic products pursue extreme thinness and performance, the importance of precision manufacturing has never been greater....

Fine Craftsmanship: The Art of Metal Bending in Sheet Metal Services

When you see the smooth curvature of a car’s fenders, the angular shells of electrical equipment, or the chic metal...

Should CNC Milling Use Climb Milling or Conventional Milling?

During CNC machining, the rotation direction of the milling cutter is generally fixed, but the feed direction often changes. Climb...

Analyzing the Differences Between CNC Machining and 3D Printing from Multiple Perspectives

What exactly are the differences between CNC machining and 3D printing?Generally speaking, 3D printing is an additive technology, while CNC...

Sharing Techniques for Machining Titanium Alloy Aerospace Parts

Precision components in the aviation and aerospace industries have extremely high requirements. This is partly due to the specific requirements...

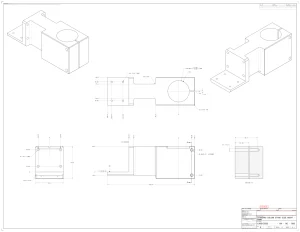

To Ensure the Machining Accuracy of Precision Parts, What Process Principles Should Be Followed During Machining?

The machining accuracy of a component affects its overall performance, assembly, and product performance. To ensure the machining accuracy of...

Not just cutting metal, but the art of precision shaping value

In the sea of stars of mechanical manufacturing, CNC (computer numerical control) machining is no longer an unfamiliar term. However,...

CNC machining: the core engine of modern intelligent manufacturing and industry insider analysis

In the field of mechanical manufacturing, CNC (Computer Numerical Control) machining is no longer an unfamiliar word. It represents a...

CNC Machining: Technological Changes and Industry Pulse, Leading a New Era of Manufacturing

In the grand narrative of “Made in China 2025”, CNC (Computer Numerical Control) machining has always been an irreplaceable core...

How Does the Content of Impurities in Aluminum Extrusion Parts Affect Their Quality During Processing?

We all know that aluminum extrusions are primarily composed of aluminum, with other metals and non-metals, such as magnesium, manganese,...

Guide to plastic materials for prototyping and production

I. Introduction In the dynamic world of product development, Prototyping plastic materials and production are crucial steps that can make...

Post-processing of SLS Printed Parts

I. Introduction In recent years, the advent of 3D printing technology has revolutionized manufacturing, and Selective Laser Sintering (SLS) has...

Key design considerations for 3D printing

1. Introduction 3D printing technology has emerged as a revolutionary force in modern manufacturing and various other fields. It enables...

Heat Treatment of CNC Machined Parts

I. Introduction In recent years, the CNC machining industry has witnessed remarkable growth, with CNC machined parts finding extensive applications...

Design guidelines for wrap forming and insert forming

I. Introduction In the dynamic world of manufacturing, wrap molding and insert molding stand as two powerful techniques that have...

Why use wrap molding and insert molding?

1. Introduction In the highly competitive landscape of CNC machining, manufacturers are constantly seeking innovative techniques to enhance product quality...

9 DFM Criteria for Part Design: A Comprehensive Guide

1. Introduction to DFM in Part Design 1.1 What is DFM? DFM, or Design for Manufacturing, is a crucial concept...

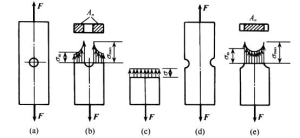

Stress concentration leads to part failure, how to effectively avoid?

I. Introduction Stress concentration is a phenomenon where stress is significantly amplified in specific areas of a part, often leading...

Overview of Four Strength Theories of Aluminum

Abstract Aluminum is a widely used metal with unique properties. This article provides an overview of the four strength theories...

What Materials Have Good Corrosion Resistance?

I. Introduction Corrosion is a pervasive and costly issue that affects various industries and our daily lives. It can cause...

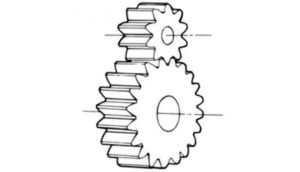

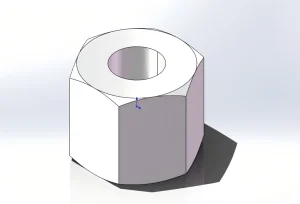

What common materials are suitable for making gears?

Gears are essential mechanical components that transmit power and motion between rotating shafts. The choice of material for making gears...

8 common machining processes, recommended collection

Machining processes play a crucial role in manufacturing. They transform raw materials into precise and functional parts. Here are 8...

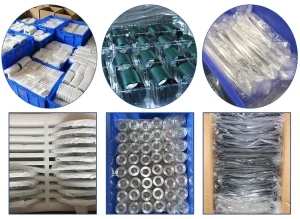

Packaging and Shipping Strategies for Safe Transportation of CNC Machined Parts

As a professional CNC processing factory, we know that every step from the product leaving the factory to the hands...

CNC Processing Plant for Collaborative Robot Parts

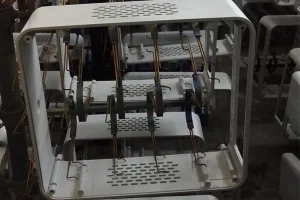

Collaborative robot parts are revolutionizing the manufacturing industry. These robots work alongside humans to enhance productivity and efficiency. At the...

Intelligent equipment parts CNC machining fast solution

1. Introduction In today’s highly developed manufacturing industry, intelligent equipment plays a crucial role in various fields. From industrial automation...

Marine equipment parts CNC machining fast solution

I. Introduction In recent years, the marine engineering industry has been booming, with the global demand for marine resources exploration,...

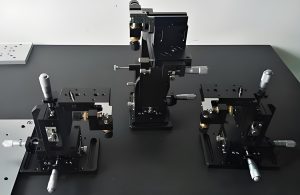

Optical communication parts CNC machining fast solution

I. Introduction In the digital age, optical communication has become the backbone of global connectivity. From high-speed internet access to...

Fast solution for CNC machining of semiconductor parts

I. Introduction In the highly competitive landscape of the electronics industry, semiconductor parts stand as the linchpin of technological advancement....

New energy parts CNC machining fast solution

I. Introduction In recent years, with the rapid development of new energy technologies, the demand for new energy parts has...

Fast solution for cnc machining medical parts

1. Introduction In recent years, the medical industry has witnessed remarkable growth, with a surging demand for sophisticated and precise...

Robot parts CNC machining fast solution

Ⅰ. Introduction In recent years, the field of robotics has witnessed remarkable advancements, revolutionizing industries across the globe. From automotive...

CNC Machining Technology of Thin-Walled Shell Parts with Easy Deformation: High-Speed Solutions

I. Introduction Thin-walled shell parts,with their lightweight and compact design, have become ubiquitous in various industries. From aerospace components that...

Application of high speed CNC machining in aircraft parts manufacturing

I. Introduction In the highly advanced realm of aircraft manufacturing, precision and efficiency are not just desirable traits but absolute...

Overview: Types of Springs and their applications

Springs: An Introduction Springs are ubiquitous mechanical components that play a crucial role in modern life. They are elastic objects...

High-Precision Multi-Hole Flange Connection Plate

I. Choosing the Right Material Eliminates the Risk of Later Defects For this component, we initially had two material options...

Aluminum alloy precision valve body

1、 Choosing the right materials saves 80% of the trouble in the later stage We use 6061-T6 aluminum alloy (compliant...

Stainless steel porous precision mechanical sleeve:the “sturdy protective umbrella” of equipment.

Introduction In industrial equipment, if there is a component that can be like a “sturdy steel armor”, tightly protecting the...

CNC-machined turbine blades: A masterpiece of precision manufacturing

Introduction In the wondrous world of CNC machining, every component is like a meticulously crafted work of art, and the...

High-precision transmission gearbox housing

Introduction In a complex mechanical system, if there is a part that can be like a “caring little housekeeper”, which...

CNC machined aluminum alloy connector: fully supports the core components

Introduction Hello everyone, I’d like to introduce this CNC-machined aluminum alloy connector. Like a meticulous butler, it securely holds all...

High – Precision CNC – Machined Aluminum Heat Sinks: The “Cool Guardians” for High – Performance Equipment Worldwide

Introduction Hey everyone! Today, I’m taking you on a journey into the fascinating world of a thermal management revolution, and...

Rapidefficient creates miniature computer case for TechSphere

BackgroundIn June 2024, we partnered with TechSphere in Tokyo. TechSphere, with operations spanning Asia, from the bustling streets of Seoul...

Rapidefficient’s Precision Craftsmanship in Smart Electronic Door Locks for Scandinavian Innovator NordicSafe Solutions

Rapidefficient views every project as a new challenge, and this one was no exception. BackgroundIn early 2023, we partnered with...

Rapidefficient’s CNC machining collaboration with North American customer SecureVision Technologies

Client Background: SecureVision Technologies, located in the vibrant tech hub of Silicon Valley, California, is a leading security technology company...

Rapidefficient Customer Collaboration Case Study – O-Net Technologies Group

Rapidefficient Customer Collaboration Case Study: O-Net Technologies Group Co., Ltd Collaboration Background O-Net Technologies (Shenzhen) Group Co., Ltd is a prominent...

Rapidefficient Customer Collaboration Case Study – Shenzhen Colibri Technologies

Rapidefficient Customer Collaboration Case Study: Shenzhen Colibri Technologies Co., Ltd Collaboration Background Shenzhen Colibri Technologies Co., Ltd is a high-tech...