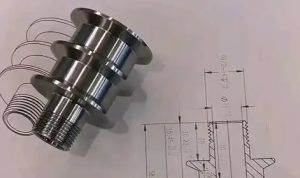

What to Prepare for a CNC Part Machining Quote

In the machining industry, CNC machining has become a mainstream choice for parts processing due to its high precision and...

Requirements for Hot Precision Forging Technology in Part Processing

1. Bevel Gear Transmission Overview Bevel gear transmissions are used to transmit motion and power between two intersecting axes in...

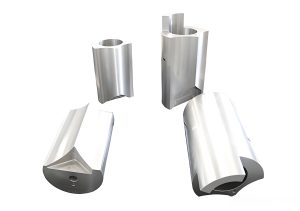

Core Characteristics of Non-standard Hardware Parts Processing

Non-standard hardware parts processing refers to the custom production of non-standard hardware parts based on specific customer requirements (such as...

What are the main considerations for the geometric angles of CNC turning and milling?

When turning slender shafts, due to the poor rigidity of the workpiece, the shapes of the turning tool have a...

Key Measures for Ensuring Dimensional Accuracy in CNC Machined Precision Parts

The dimensional accuracy of precision parts directly impacts product quality and performance. Achieving high-precision machining requires a systematic approach, including...

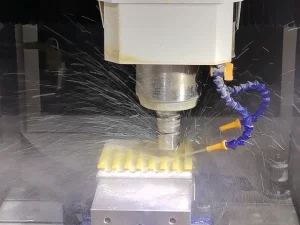

How to improve and solve the poor surface accuracy of CNC machining?

In CNC machining, surface accuracy is one of the most critical indicators of part quality, directly affecting assembly precision, wear...

Why is the material selection important for CNC turning and milling?

In CNC turning-milling, material selection directly impacts machining efficiency, part accuracy, surface quality, and final performance. Its importance lies in...

Analysis of Troubleshooting Handwheel Failures During CNC Machining

CNC machining is widely used across industries and manufacturers. During the manufacturing process, unexpected or human-caused failures are unavoidable, particularly...

Analysis of Causes of Oil Leakage in CNC Machining Centers

During CNC machining, unexpected issues often arise, but no matter what they are, they must be addressed promptly. Oil leaks...

What Problems Can Arise from Improperly Arranging CNC Machining Processes?

1. Excessively Fragmented CNC Machining Processes This problem arises from a fear of complexity (referring to setup time), a preference...

How to prevent common wear problems in part machining?

Common types of wear in part machining include: Run-in Wear Run-in wear is wear that occurs when a machine tool...

What factors should be considered when selecting cutting tools?

When selecting cutting tools, appropriate cutting tools and tool holders should be selected based on the function of the machining...

How to ensure the accuracy and stability of parts during processing?

The Significance of Part Accuracy and Stability In the world of manufacturing, especially in CNC machining, the accuracy and stability...

The Truth about the Accuracy of Parts in CNC Machining

The Misconception of Higher Part Accuracy In the field of CNC machining, many people hold a common misconception that the...

Processing technology of shaft parts

Shaft parts are essential components in numerous mechanical and industrial applications. Their proper processing is crucial to ensure the smooth...

The role of nickel plating on aluminum alloy

Aluminum alloy is a widely used material in various industries due to its excellent properties such as lightweight, good conductivity,...

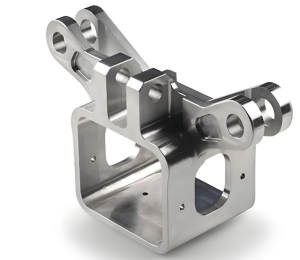

Advantages and disadvantages of CNC machining hardware parts

In the modern manufacturing industry, CNC machining has become a crucial process for producing high-quality hardware parts. CNC (Computer Numerical...

How to improve UAV parts processing efficiency and reduce waste

In today’s rapidly evolving technological landscape, unmanned aerial vehicles (UAVs) have become increasingly popular in various fields such as surveillance,...

Precision machining technology and process for mold parts

In the field of manufacturing, precision machining of mold parts plays a crucial role. Mold parts are essential components in...

Sheet metal stamping technology and application

Sheet metal stamping technology is a crucial manufacturing process that has been widely used in various industries. In this article,...

Challenges and Advances in Irregularly Shaped Parts Processing

Introduction The manufacturing of irregularly shaped parts presents unique challenges to engineers, designers, and manufacturers. Unlike standard geometries, irregular parts...

6 Essential Knowledge Points for Stainless Steel Machining

Introduction: Stainless steel machining is a critical process in many industries, from aerospace to medical devices. Its high strength, durability,...

Detailed explanation of CNC machining accuracy

1. Introduction to CNC Machining Accuracy CNC (Computer Numerical Control) machining has become one of the most crucial methods of...

Applications of Teflon Materials in the Machining Industry

Introduction: Teflon, a brand name for polytetrafluoroethylene (PTFE), has gained widespread popularity in the machining industry due to its exceptional...

Precision Manufacturing, Protecting Lives: CNC Machining is the core solution in the field of medical devices

Under the shadowless light, the titanium alloy orthopedic implant in the surgeon’s hand is accurately fitting the patient’s bone; In...

Rapidefficient: Your expert in CNC machining service solutions

In the modern manufacturing battlefield that pursues efficiency and precision, the precision parts behind every product are the silent declaration...

The Duo of Speed and Precision: The Winning Way to Choose a CNC Machining Service Provider

In today’s rapid-paced manufacturing arena, “time is money” is no empty phrase. Production line shutdown due to delays in critical...

How Rapid Efficient Pushes CNC Machining Services to New Heights of Efficiency

In today’s competitive manufacturing landscape, precision and efficiency are the lifeblood of survival. Enterprises are not only looking for qualified...

How do we address the issue of poor after-sales service for parts?

The manufacturing industry is developing rapidly, and competition in the CNC machining industry is becoming increasingly fierce. Poor after-sales service...

Strategies for dealing with material changes and dimensional errors in CNC lathe machining

CNC lathe machining plays a vital role in modern manufacturing due to its high precision and efficiency. However, fluctuations in...

Strategies to improve CNC machining efficiency of non-standard parts

In the manufacturing industry, CNC machining of non-standard mechanical parts is a complex and delicate process. Improving the efficiency of...

CNC machining small batch and proofing efficiency improvement strategy: matching new product development progress

In the process of new product development, small-batch production and proofing of CNC machining often become key factors affecting the...

Optimize CNC machining delivery management: improve production planning efficiency and coordination

Frequent delays in CNC machining delivery not only affect the stability of production plans, but also increase the cost and...

Treatment and prevention strategies of defective products in CNC machining

In the field of CNC machining, the appearance of defective products not only affects production efficiency, but may also have...

How do we handle customer feedback and complaints?

In the CNC processing industry, customer feedback and complaints are important bases for companies to continuously improve and enhance service...

The most common defects and solutions for CNC machining of parts

CNC machining is a high-precision manufacturing technology, but it may also encounter some common machining defects. Understanding these defects and...

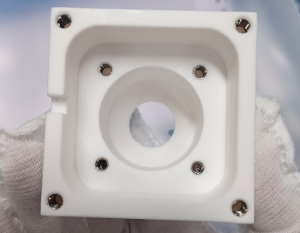

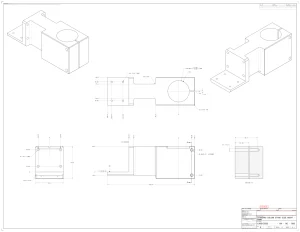

High-Precision Multi-Hole Flange Connection Plate

I. Choosing the Right Material Eliminates the Risk of Later Defects For this component, we initially had two material options...

Aluminum alloy precision valve body

1、 Choosing the right materials saves 80% of the trouble in the later stage We use 6061-T6 aluminum alloy (compliant...

Stainless steel porous precision mechanical sleeve:the “sturdy protective umbrella” of equipment.

Introduction In industrial equipment, if there is a component that can be like a “sturdy steel armor”, tightly protecting the...

CNC-machined turbine blades: A masterpiece of precision manufacturing

Introduction In the wondrous world of CNC machining, every component is like a meticulously crafted work of art, and the...

High-precision transmission gearbox housing

Introduction In a complex mechanical system, if there is a part that can be like a “caring little housekeeper”, which...

CNC machined aluminum alloy connector: fully supports the core components

Introduction Hello everyone, I’d like to introduce this CNC-machined aluminum alloy connector. Like a meticulous butler, it securely holds all...

High – Precision CNC – Machined Aluminum Heat Sinks: The “Cool Guardians” for High – Performance Equipment Worldwide

Introduction Hey everyone! Today, I’m taking you on a journey into the fascinating world of a thermal management revolution, and...

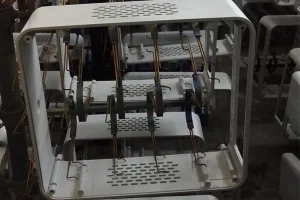

Rapidefficient creates miniature computer case for TechSphere

BackgroundIn June 2024, we partnered with TechSphere in Tokyo. TechSphere, with operations spanning Asia, from the bustling streets of Seoul...

Rapidefficient’s Precision Craftsmanship in Smart Electronic Door Locks for Scandinavian Innovator NordicSafe Solutions

Rapidefficient views every project as a new challenge, and this one was no exception. BackgroundIn early 2023, we partnered with...

Rapidefficient’s CNC machining collaboration with North American customer SecureVision Technologies

Client Background: SecureVision Technologies, located in the vibrant tech hub of Silicon Valley, California, is a leading security technology company...

Rapidefficient Customer Collaboration Case Study – O-Net Technologies Group

Rapidefficient Customer Collaboration Case Study: O-Net Technologies Group Co., Ltd Collaboration Background O-Net Technologies (Shenzhen) Group Co., Ltd is a prominent...

Rapidefficient Customer Collaboration Case Study – Shenzhen Colibri Technologies

Rapidefficient Customer Collaboration Case Study: Shenzhen Colibri Technologies Co., Ltd Collaboration Background Shenzhen Colibri Technologies Co., Ltd is a high-tech...