CNC Machining: Precision Manufacturing Magicians for Custom Parts and Rapid Prototyping

In today’s high-speed operation of innovation and iteration, when you hold breakthrough product design drawings or face the dilemma of...

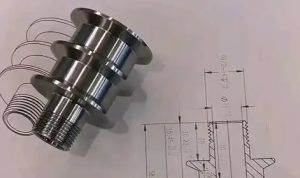

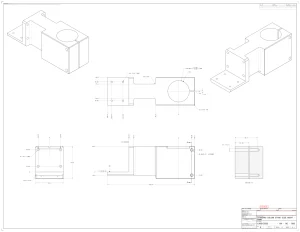

What to Prepare for a CNC Part Machining Quote

In the machining industry, CNC machining has become a mainstream choice for parts processing due to its high precision and...

Requirements for Hot Precision Forging Technology in Part Processing

1. Bevel Gear Transmission Overview Bevel gear transmissions are used to transmit motion and power between two intersecting axes in...

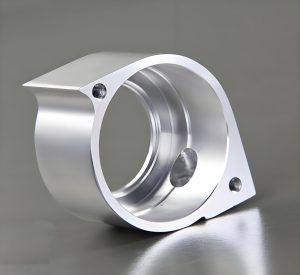

Core Characteristics of Non-standard Hardware Parts Processing

Non-standard hardware parts processing refers to the custom production of non-standard hardware parts based on specific customer requirements (such as...

What are the main considerations for the geometric angles of CNC turning and milling?

When turning slender shafts, due to the poor rigidity of the workpiece, the shapes of the turning tool have a...

Key Measures for Ensuring Dimensional Accuracy in CNC Machined Precision Parts

The dimensional accuracy of precision parts directly impacts product quality and performance. Achieving high-precision machining requires a systematic approach, including...

How to improve and solve the poor surface accuracy of CNC machining?

In CNC machining, surface accuracy is one of the most critical indicators of part quality, directly affecting assembly precision, wear...

Why is the material selection important for CNC turning and milling?

In CNC turning-milling, material selection directly impacts machining efficiency, part accuracy, surface quality, and final performance. Its importance lies in...

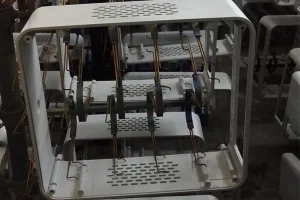

Analysis of Troubleshooting Handwheel Failures During CNC Machining

CNC machining is widely used across industries and manufacturers. During the manufacturing process, unexpected or human-caused failures are unavoidable, particularly...

Analysis of Causes of Oil Leakage in CNC Machining Centers

During CNC machining, unexpected issues often arise, but no matter what they are, they must be addressed promptly. Oil leaks...

What Problems Can Arise from Improperly Arranging CNC Machining Processes?

1. Excessively Fragmented CNC Machining Processes This problem arises from a fear of complexity (referring to setup time), a preference...

How to prevent common wear problems in part machining?

Common types of wear in part machining include: Run-in Wear Run-in wear is wear that occurs when a machine tool...

Achieve High Precision with Expert Mechanical Machining Solutions

Introduction High precision mechanical machining solutions are essential for modern industries where exactness and performance are paramount. From aerospace to...

Discover Custom CNC Mechanical Machining Services Tailored to Your Needs

Introduction In the competitive world of manufacturing, precision is crucial. Custom CNC mechanical machining services have become essential for...

What are the steps of CNC machining?

In today’s era of rapid technological development, CNC machining has become an indispensable part of the manufacturing industry. It not...

The Advantages and Applications of CNC Aluminum Machining in Modern Manufacturing

ABSTRACT This paper discusses the importance of CNC aluminum machining in modern manufacturing. It elaborates on the research background and...

Aerospace-Grade Aluminum Machining: Precision in the Skies

1、Understanding Aerospace-Grade Aluminum Machining Aerospace-grade aluminum machining plays a crucial role in the aerospace industry. Aerospace-grade aluminum is a specialized...

CNC Aluminum Machining Tolerances

ABSTRACT This paper provides a comprehensive analysis of CNC aluminum machining tolerances. Key factors determining these tolerances are identified, including...

CNC Aluminum Machining: Unleashing Precision and Efficiency

I. Core Perspectives 1.1 Key Processes Driving Transformations in Manufacturing CNC Aluminum Processing: A Vital Technology in Modern Manufacturing CNC...

CNC Aluminum Prototype Machining: Unleashing Precision and Innovation

一、Understanding CNC Aluminum Prototype Machining (一)What is CNC Aluminum Prototype Machining? CNC aluminum prototype machining refers to the process of...

Research Report on Aerospace CNC Aluminum Machining

1. Core Viewpoints 1.1 Key Manufacturing Technology Driving Aerospace Development Aerospace CNC aluminum machining is of crucial significance in the...

Rapidefficient creates miniature computer case for TechSphere

BackgroundIn June 2024, we partnered with TechSphere in Tokyo. TechSphere, with operations spanning Asia, from the bustling streets of Seoul...

Rapidefficient’s Precision Craftsmanship in Smart Electronic Door Locks for Scandinavian Innovator NordicSafe Solutions

Rapidefficient views every project as a new challenge, and this one was no exception. BackgroundIn early 2023, we partnered with...

Rapidefficient’s CNC machining collaboration with North American customer SecureVision Technologies

Client Background: SecureVision Technologies, located in the vibrant tech hub of Silicon Valley, California, is a leading security technology company...

Rapidefficient Customer Collaboration Case Study – O-Net Technologies Group

Rapidefficient Customer Collaboration Case Study: O-Net Technologies Group Co., Ltd Collaboration Background O-Net Technologies (Shenzhen) Group Co., Ltd is a prominent...

Rapidefficient Customer Collaboration Case Study – Shenzhen Colibri Technologies

Rapidefficient Customer Collaboration Case Study: Shenzhen Colibri Technologies Co., Ltd Collaboration Background Shenzhen Colibri Technologies Co., Ltd is a high-tech...

Affordable Mechanical Machining Services Without Compromising Quality

Introduction In today’s manufacturing world, finding affordable mechanical machining services that also deliver quality and reliability is crucial. Businesses across...