In the realm of aviation, precision is not just a requirement; it’s a necessity. Every component, from the smallest screw to the largest engine part, must be manufactured with utmost accuracy to ensure safety, efficiency, and reliability. This is where Aeronautical precision parts come into play, and CNC lathe machining stands out as a critical process in their production.

The Importance of Precision in Aviation

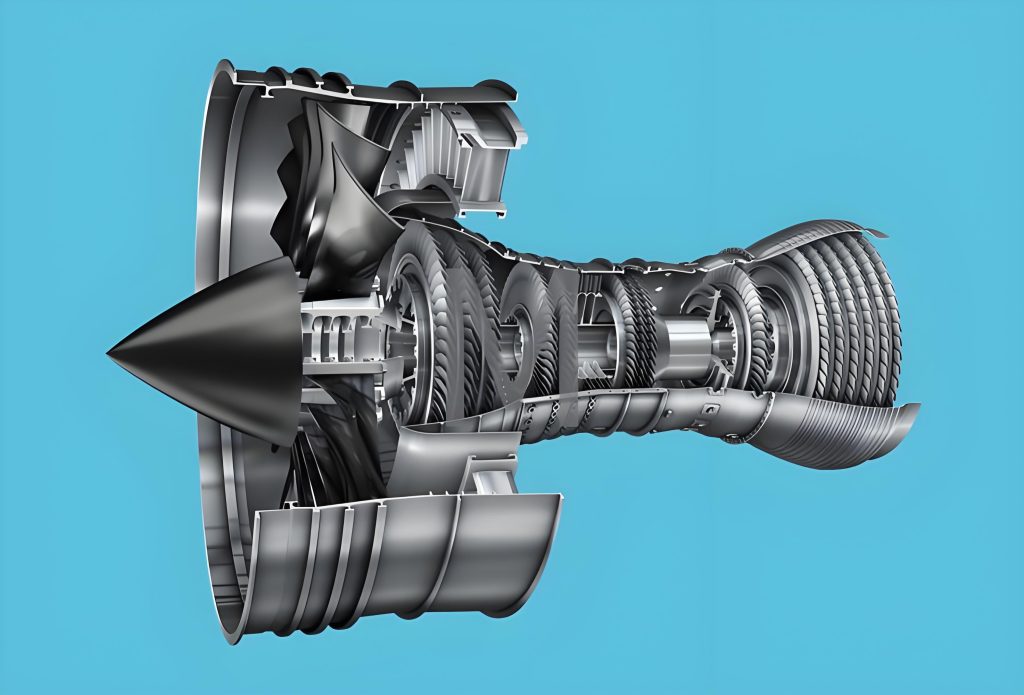

Aviation components operate under extreme conditions—high speeds, fluctuating temperatures, and intense pressures. Even the slightest deviation in manufacturing can lead to catastrophic failures. Precision parts are the backbone of aerospace engineering, ensuring that aircraft and spacecraft function flawlessly. For example, turbine blades in aircraft engines must withstand extreme temperatures and forces while maintaining optimal aerodynamic efficiency.

CNC Lathe Machining: The Process

CNC lathe machining is a highly precise method used to create aeronautical components. It involves rotating the workpiece while a cutting tool shapes it. This process allows for tight tolerances and complex geometries, essential for aviation parts. Modern CNC lathes are equipped with advanced technologies that enable micron-level accuracy, making them ideal for manufacturing components like fuel nozzles and hydraulic actuators.

Materials Used in Aeronautical Precision Parts

The choice of materials is as critical as the precision of the manufacturing process. Common materials include titanium, known for its strength-to-weight ratio and corrosion resistance, and high-strength alloys like Inconel, which can withstand extreme temperatures. Aluminum is also widely used due to its lightweight and durability.

Challenges and Solutions

Manufacturing aeronautical precision parts is not without challenges. Tight tolerances, complex geometries, and the need for rigorous testing and inspection all add to the complexity. However, advancements in CNC technology, such as 5-axis machining and wire EDM, have made it possible to achieve the highest levels of precision. Companies like Owens Industries specialize in these advanced techniques, ensuring that even the most complex components are manufactured to exact specifications.

The Role of Rapidefficient

In the competitive landscape of CNC machining, rapidefficient stands out as a leader. They offer rapid and efficient solutions for CNC aluminum processing, ensuring that clients receive high-quality parts in the shortest possible time. Their commitment to precision and efficiency makes them a trusted partner for aviation companies worldwide.

Future Trends

As the aviation industry continues to evolve, the demand for lighter, more efficient, and sustainable materials will increase. Future trends include the use of advanced composites and eco-friendly manufacturing processes. Additionally, digital replicas and innovative propulsion technologies will play a significant role in shaping the future of flight.

Conclusion

CNC lathe machining is a cornerstone of aeronautical precision parts manufacturing. It combines advanced technology with meticulous craftsmanship to produce components that meet the stringent demands of the aviation industry. With companies like rapidefficient leading the way, the future of aviation manufacturing looks promising.

About Rapidefficient

Rapidefficient is a leading provider of CNC aluminum processing services. They specialize in delivering high-quality, precision-machined parts with rapid turnaround times. Whether you need custom components for aircraft engines or intricate parts for avionics systems, Rapidefficient has the expertise and technology to meet your needs.