1. Introduction

In the realm of modern manufacturing, CNC machining has revolutionized the production of aluminum enclosures. These enclosures serve a crucial role in protecting sensitive components and systems across various industries. This article delves into the world of CNC machining for aluminum enclosures, exploring the processes, advantages, and the exceptional services provided by Rapidefficient.

2. The Importance of Aluminum Enclosures

Aluminum enclosures are widely favored due to their unique set of properties. Aluminum is lightweight yet offers remarkable strength, making it ideal for applications where portability and durability are essential. It has excellent corrosion resistance, which ensures the longevity of the enclosure, especially in harsh or humid environments. Additionally, aluminum’s good thermal conductivity helps in dissipating heat generated by the enclosed components, thereby enhancing the overall performance and reliability of the system.

3. The CNC Machining Process for Aluminum Enclosures

3.1 Design Phase

The first step in CNC machining aluminum enclosures is the design. Utilizing advanced Computer-Aided Design (CAD) software, engineers create a detailed 3D model of the enclosure. This model precisely defines the enclosure’s dimensions, shape, and any specific features such as cutouts for connectors, vents for heat dissipation, or mounting holes. The CAD design allows for easy modifications and optimization, ensuring that the enclosure meets all functional and aesthetic requirements.

3.2 Material Selection

Choosing the right aluminum alloy is a critical aspect. Different alloys have varying levels of strength, hardness, and corrosion resistance. For example, 6061 aluminum is commonly used for its good balance of strength and formability, making it suitable for enclosures that require moderate strength and ease of machining. On the other hand, 7075 aluminum offers higher strength and is preferred for applications where greater mechanical performance is needed. Rapidefficient offers a wide range of aluminum alloy options to meet the specific demands of different enclosure projects.

3.3 Machining Operations

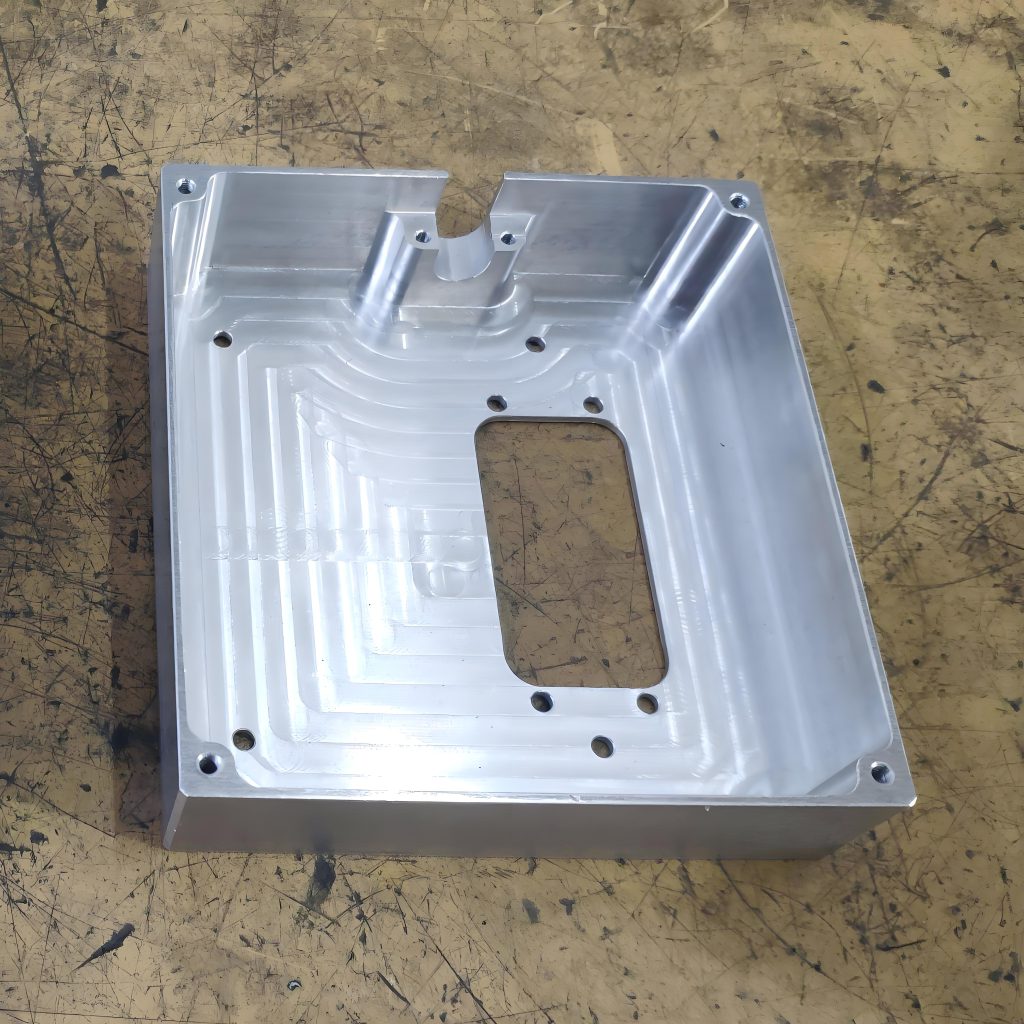

3.3.1 Milling

Milling is a fundamental process in creating aluminum enclosures. The CNC milling machine uses rotating cutting tools to remove material from the aluminum workpiece. It can perform various operations such as face milling, contour milling, and pocket milling. With high-precision control of the tool’s movement in multiple axes (usually three or five axes), complex shapes and features of the enclosure can be achieved. Rapidefficient’s milling machines are equipped with advanced spindle systems and tool changers, enabling efficient and accurate machining. For instance, in creating the exterior surface of an enclosure, face milling is used to obtain a smooth and flat finish, while contour milling is employed to shape the edges and curves.

3.3.2 Turning

Although enclosures are predominantly rectangular or box-shaped, some components within the enclosure may require turning operations. Turning is used to create cylindrical or rotational features. The aluminum workpiece is rotated while a stationary cutting tool shapes the surface. This is useful for manufacturing parts like shafts or connectors that might be integrated into the enclosure. Rapidefficient’s CNC turning centers are capable of high-precision turning, ensuring the proper fit and function of these internal components.

3.3.3 Drilling and Tapping

Drilling is essential for creating holes in the enclosure for screws, bolts, or other fasteners. Tapping is then performed to create internal threads, allowing for secure assembly. CNC machines accurately control the position, depth, and diameter of the holes and threads. Rapidefficient employs advanced drilling and tapping techniques to ensure that the holes are precisely placed and the threads are of high quality. This is crucial for the integrity of the enclosure’s assembly and for withstanding any mechanical stresses.

3.4 Surface Finishing

After the machining operations, surface finishing is carried out to enhance the appearance and functionality of the aluminum enclosure. This can include processes such as anodizing, painting, or powder coating. Anodizing forms a protective oxide layer on the surface, increasing corrosion resistance and providing a decorative finish. Painting and powder coating offer a wide range of color options and can further protect the enclosure from scratches and environmental damage. Rapidefficient provides comprehensive surface finishing services, allowing customers to choose the finish that best suits their application and aesthetic preferences.

3.5 Quality Control

Quality control is an integral part of the CNC machining process for aluminum enclosures. Rapidefficient employs a series of inspection techniques and tools. Coordinate Measuring Machines (CMMs) are used to measure the dimensions of the enclosure and compare them with the design specifications. Visual inspections are carried out to check for any surface defects or machining errors. Additionally, functional tests may be performed to ensure that the enclosure meets all performance requirements, such as proper fitment of components and effective heat dissipation.

4. Advantages of CNC Machining for Aluminum Enclosures

4.1 Precision and Accuracy

CNC machines are capable of achieving extremely tight tolerances. This ensures that the aluminum enclosures are manufactured with precise dimensions, which is crucial for the proper fit and function of the enclosed components. For example, in electronics enclosures, accurate cutouts for circuit boards and connectors are essential to avoid any interference or misalignment.

4.2 Complex Geometries

The flexibility of CNC machining allows for the creation of enclosures with complex geometries. Intricate designs, such as curved surfaces, angled edges, and recessed features, can be easily produced. This enables manufacturers to design enclosures that not only meet functional requirements but also have an aesthetically pleasing appearance.

4.3 High Production Efficiency

Automated CNC machining processes can produce aluminum enclosures in large quantities with consistent quality. Once the program is set up, the machines can run continuously, reducing production time and costs. Rapidefficient’s CNC machining facilities are optimized for high-volume production, ensuring timely delivery of enclosures to meet market demands.

4.4 Customization

Each project may have unique requirements for the aluminum enclosure. CNC machining allows for easy customization. Whether it’s a specific size, shape, or a combination of features, the machining process can be adjusted accordingly. Rapidefficient offers customized CNC machining solutions, working closely with customers to bring their unique enclosure designs to life.

5. Rapidefficient’s CNC Machining Services for Aluminum Enclosures

5.1 Advanced Machining Technologies

Rapidefficient utilizes state-of-the-art CNC machining technologies. Their machines are equipped with high-speed spindles that enable rapid material removal while maintaining accuracy. The multi-axis machining capabilities (up to five axes) allow for the production of highly complex enclosure designs in a single setup, reducing production time and minimizing errors.

5.2 Prototype to Production Services

Whether it’s a single prototype for testing and design validation or a large-scale production run, Rapidefficient has the expertise and resources to handle it. They can quickly turn around prototypes, allowing customers to assess the design and make any necessary modifications early in the development process. Once the prototype is approved, they seamlessly transition to full-scale production, ensuring a smooth and efficient manufacturing flow.

5.3 Material and Finish Options

As mentioned earlier, Rapidefficient offers a wide selection of aluminum alloys for enclosure manufacturing. They also provide a diverse range of surface finishing options. From anodizing in various colors and finishes to painting and powder coating with different textures and gloss levels, customers can choose the combination that best suits their product’s branding and environmental requirements.

5.4 Engineering Support

Rapidefficient has a team of experienced engineers who provide valuable support throughout the CNC machining process. They assist in design optimization, ensuring that the enclosure is manufacturable with the highest quality and at the lowest cost. The engineers also offer technical advice on material selection, machining strategies, and quality control measures, helping customers make informed decisions.

6. Case Studies of Rapidefficient’s Aluminum Enclosure Projects

6.1 Electronics Enclosure for a High-End Audio Device

A leading audio equipment manufacturer approached Rapidefficient to produce aluminum enclosures for a new high-end audio device. The enclosure required a sleek and modern design with precise cutouts for buttons, knobs, and audio connectors. Rapidefficient’s engineers worked closely with the client to optimize the design for CNC machining. Using their five-axis milling machines, they were able to create the complex curved surfaces and accurate cutouts with ease. The enclosures were then anodized to a matte black finish, giving them a premium look. The final product not only provided excellent protection for the audio components but also enhanced the overall aesthetic appeal of the device, contributing to its success in the market.

6.2 Industrial Control Enclosure for a Manufacturing Plant

An industrial automation company needed aluminum enclosures for their control systems used in a manufacturing plant. The enclosures had to be rugged and durable, with good heat dissipation properties. Rapidefficient selected a high-strength aluminum alloy and used a combination of milling and drilling operations to create the enclosures. They incorporated strategically placed vents and fins for enhanced heat dissipation. The enclosures were powder coated in a corrosion-resistant finish. The result was a reliable and long-lasting enclosure that met the harsh operating conditions of the manufacturing plant, ensuring the uninterrupted operation of the industrial control systems.

7. Why Choose Rapidefficient for CNC Machining of Aluminum Enclosures

7.1 Quality and Reliability

Rapidefficient has a proven track record of delivering high-quality aluminum enclosures. Their strict quality control processes and advanced machining technologies ensure that each enclosure meets or exceeds industry standards. Customers can rely on the precision and durability of the enclosures produced by Rapidefficient.

7.2 Technical Expertise

The company’s team of engineers and machinists possess extensive technical expertise in CNC machining for aluminum enclosures. They are well-versed in the latest machining techniques and can handle complex design challenges. Their knowledge and experience translate into efficient manufacturing processes and superior product quality.

7.3 Timely Delivery

In today’s fast-paced business environment, timely delivery is crucial. Rapidefficient has efficient project management systems in place to ensure that aluminum enclosures are delivered on schedule. They understand the importance of meeting production deadlines and work hard to avoid any delays.

7.4 Competitive Pricing

Despite offering top-notch quality and services, Rapidefficient provides competitive pricing. They offer cost-effective solutions that fit within the budget constraints of different customers. Their pricing model is transparent, and they strive to provide value for money in every project.

8. Conclusion

CNC machining for aluminum enclosures is a vital manufacturing process that offers precision, efficiency, and customization. Rapidefficient emerges as a leading provider of CNC machining services in this domain. With their advanced technologies, comprehensive service offerings, and commitment to quality and customer satisfaction, Rapidefficient is the ideal choice for businesses seeking high-quality aluminum enclosures. Whether it’s for the electronics, industrial, or any other sector, partnering with Rapidefficient ensures that your aluminum enclosure needs are met with excellence and professionalism.