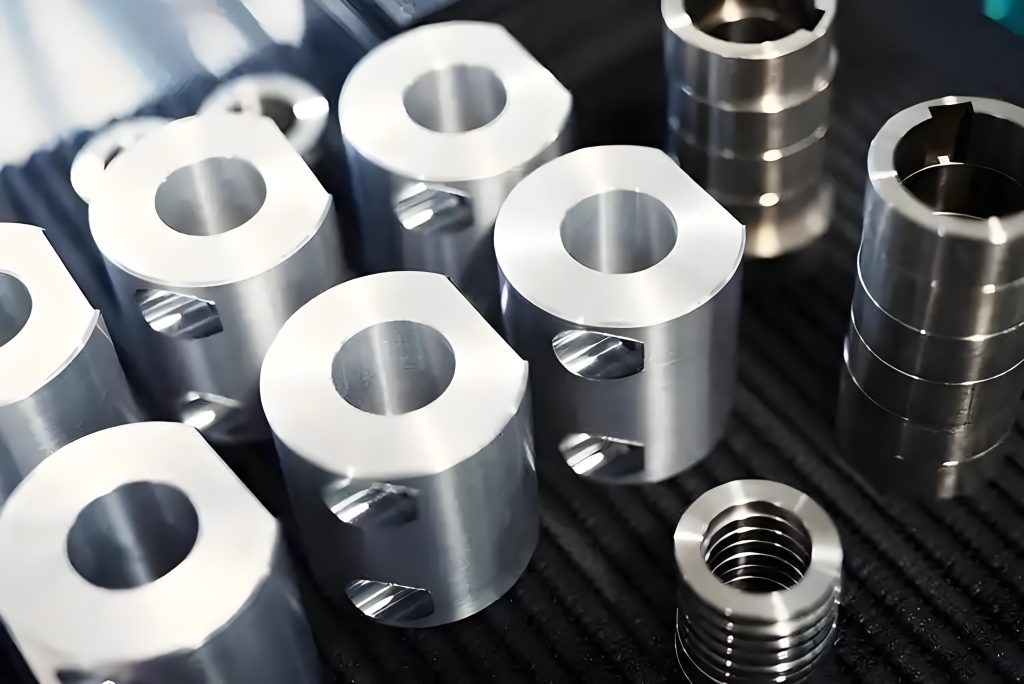

Custom metal part fabrication and machining are essential services across numerous industries, from automotive and aerospace to healthcare and electronics. By producing highly specialized metal parts, companies can create customized solutions that meet exact specifications. This article explores the benefits of custom metal part fabrication and machining, focusing on the expertise of Rapidefficient, a leading provider in precision machining services.

The Importance of Custom Metal Part Fabrication

Custom metal part fabrication provides tailored solutions for businesses that require specific dimensions, shapes, or functionalities. Unlike mass-produced parts, custom fabrication allows for design flexibility, offering components that meet exact performance requirements.

Design Flexibility: Custom fabrication offers the freedom to design parts that meet unique needs. Complex geometries, custom sizes, and special finishes are all achievable.

Quality Assurance: Custom parts go through stringent quality checks, ensuring that they meet high-performance standards.

Cost Efficiency: By reducing waste and optimizing material usage, custom fabrication provides a cost-effective solution, particularly for specialized or high-value applications.

Applications of Custom Metal Part Fabrication and Machining

Custom metal part fabrication and machining support various industries by providing components essential to their functionality and durability.

Automotive: Custom parts for engines, exhaust systems, and structural supports contribute to better performance and fuel efficiency.

Aerospace: Components such as brackets, frames, and housings require precision machining to withstand high stress and temperature.

Medical Devices: Medical applications need precision components, such as surgical tools, prosthetics, and custom fittings, all manufactured with high-quality materials.

Electronics: Heat sinks, enclosures, and connectors benefit from custom fabrication, which enhances durability and performance in electronic devices.

Rapidefficient: Leading the Custom Metal Fabrication Market

Rapidefficient specializes in custom metal part fabrication and machining, with a focus on quality, speed, and precision. Known for its advanced CNC machining capabilities, Rapidefficient consistently delivers parts that meet complex specifications and high industry standards.

Advanced CNC Machining: Rapidefficient employs state-of-the-art CNC equipment to provide parts with tight tolerances and accurate dimensions. This capability is essential in industries where precision is non-negotiable.

Material Versatility: From stainless steel and aluminum to titanium and specialized alloys, Rapidefficient works with a variety of materials to meet diverse client needs.

Rapid Prototyping: Rapidefficient’s fast prototyping services help businesses test and refine designs before full-scale production. This accelerates the development cycle, saving time and resources.

Stringent Quality Control: Every part produced undergoes rigorous testing and quality checks to ensure it meets client specifications and industry standards. Rapidefficient’s commitment to quality makes it a trusted partner in custom metal fabrication.

Benefits of Custom Metal Part Fabrication with Rapidefficient

Custom metal part fabrication and machining with Rapidefficient offer several advantages for companies aiming to enhance their production capabilities.

Precision and Consistency

Rapidefficient ensures high-quality parts that adhere to exact specifications, which is crucial for applications that require uniformity and precision.

Scalability

Rapidefficient’s services can support both small-batch and large-scale production, giving clients the flexibility to produce exactly what they need without incurring excess costs.

On-Time Delivery

With efficient production processes and strong project management, Rapidefficient delivers parts on schedule, ensuring that clients can keep their projects on track.

Cost Savings

By optimizing material usage and reducing waste, Rapidefficient offers cost-effective solutions that help businesses manage budgets without compromising on quality.

The Custom Fabrication Process at Rapidefficient

Rapidefficient follows a meticulous process to deliver custom metal parts that meet the highest standards of quality and functionality. Here’s an overview of their approach:

Design Consultation: Rapidefficient’s engineers collaborate with clients to understand their design requirements, material needs, and specifications.

Prototyping: Using advanced CNC machining, Rapidefficient creates prototypes for testing and validation, ensuring the design performs as expected.

Production: Once approved, the parts move to production, where Rapidefficient’s team uses CNC machines to fabricate parts with consistent quality.

Quality Assurance: Each part undergoes quality checks to confirm that it meets industry standards and client expectations.

Delivery: With efficient logistics, Rapidefficient ensures parts are delivered on time, helping clients maintain their production schedules.

Conclusion

Custom metal part fabrication and machining enable industries to meet specific needs, improve efficiency, and optimize performance. With its focus on precision, speed, and high-quality materials, Rapidefficient provides reliable solutions that cater to the unique demands of each client. Companies in automotive, aerospace, medical, and electronics industries can trust Rapidefficient for their custom metal part fabrication needs. Connect with Rapidefficient today to discover how their expertise in CNC machining can enhance your production processes.