Introduction

In the automotive industry, plastic parts play a crucial role in modern vehicle manufacturing. They are used in various components, from interior dashboards to exterior body panels. The demand for high – quality, precise plastic automotive parts has been on the rise, and this is where customized precision CNC machine tool services come into play. These services offer a level of accuracy and efficiency that is essential for meeting the strict requirements of the automotive sector.

Custom precision CNC machine tools are not just another manufacturing option; they are a game – changer. They allow for the production of complex plastic parts with tight tolerances, ensuring a perfect fit and optimal performance in vehicles. With the ability to work with different types of plastics, these machines can create everything from lightweight, durable structural components to aesthetically pleasing interior elements. The rapid and efficient nature of CNC machining also means that manufacturers can produce large quantities of parts in a short period, keeping up with the high – volume demands of the automotive market.

Understanding Custom Precision CNC Machine Tools

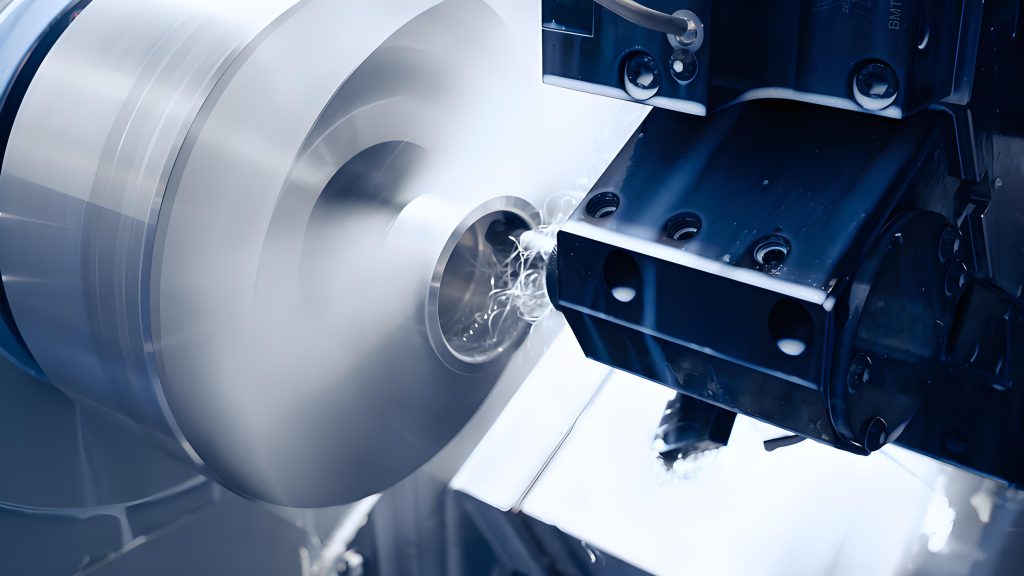

Custom precision CNC (Computer Numerical Control) machine tools are advanced manufacturing devices that use pre-programmed computer software to control the movement of tools and materials. These machines are capable of performing a wide range of operations, such as cutting, drilling, milling, and turning, with an extremely high degree of accuracy.

The working principle of CNC machine tools involves the use of a computer program that dictates the movement of the machine’s axes. These axes can move in multiple directions, allowing for the creation of complex shapes. For plastic automotive parts, this means that even the most intricate designs can be replicated with precision. The program is written based on the CAD (Computer-Aided Design) model of the part, ensuring that every detail is accounted for.

One of the key features of custom precision CNC machine tools is their ability to achieve tight tolerances. In the automotive industry, where parts need to fit together perfectly, this is crucial. For example, a plastic dashboard component must fit precisely into the vehicle’s interior without any gaps or misalignments. CNC machine tools can achieve tolerances within a few thousandths of an inch, ensuring a perfect fit every time.

Another advantage is their flexibility. They can work with different types of plastics, including ABS, polycarbonate, and nylon, which are commonly used in automotive parts. Whether it’s a hard, durable exterior panel or a soft, comfortable interior trim, CNC machine tools can handle the material with ease. This flexibility also extends to the production volume. They can be used for small – batch production, such as prototypes or limited – edition vehicle parts, as well as high – volume production runs for mass – produced cars.

The speed of CNC machine tools is also remarkable. Once the program is set up, the machine can operate continuously, producing parts at a rapid pace. This, combined with their accuracy, makes them highly efficient for manufacturing plastic automotive parts. The reduced need for manual intervention not only speeds up the production process but also minimizes the risk of human – error, further enhancing the quality of the parts.

The Significance in Plastic Automotive Parts Production

The production of plastic automotive parts demands a high level of precision and efficiency, and custom precision CNC machine tool services are vital in meeting these demands.

First and foremost, these services significantly boost production efficiency. In the automotive industry, time is money. With the rapid and continuous operation of CNC machine tools, large volumes of plastic parts can be produced in a short time. For example, in the production of plastic door panels for cars, a well – programmed CNC machine can churn out dozens of parts per hour, far exceeding the output of manual or less advanced manufacturing methods. This high – speed production helps automotive manufacturers keep up with the market’s insatiable demand for vehicles, reducing production lead times and getting new models to market faster.

Quality is another critical aspect. The tight tolerances achievable by custom precision CNC machine tools ensure that every plastic automotive part meets the strictest quality standards. In a vehicle, parts need to fit together perfectly to ensure proper functionality and safety. A misaligned plastic part in the engine compartment could potentially cause a malfunction, while an ill – fitting interior component could detract from the overall driving experience. CNC – machined plastic parts, with their high precision, minimize such risks. They provide a consistent level of quality, part after part, batch after batch. This not only improves the performance of the vehicles but also reduces the need for costly rework and recalls, saving manufacturers both time and money in the long run.

Moreover, CNC machine tools can handle complex designs with ease. As automotive design becomes more innovative, plastic parts are required to have intricate shapes and features. Whether it’s a uniquely designed dashboard with integrated controls or aerodynamic exterior plastic components, custom precision CNC machine tools can bring these designs to life. They can create undercuts, holes, and complex curves that would be extremely difficult, if not impossible, to achieve through traditional manufacturing methods. This allows automotive designers to push the boundaries of creativity, knowing that their designs can be accurately produced.

How RapidEfficient Stands Out

Precision and Quality Assurance

RapidEfficient sets itself apart in the field of custom precision CNC machining for plastic automotive parts through its unwavering commitment to precision and quality. The company is equipped with state – of – the – art CNC machine tools that are engineered to deliver an exceptional level of accuracy. These machines are regularly calibrated and maintained to ensure that every cut, drill, and mill operation is executed with pinpoint precision.

In addition to advanced equipment, RapidEfficient has implemented a rigorous quality control system. Every plastic automotive part that undergoes production is meticulously inspected at multiple stages of the manufacturing process. This includes in – process inspections to catch any potential issues early on and final inspections to guarantee that the finished product meets or exceeds the industry’s strict quality standards. The use of high – precision measuring instruments, such as coordinate measuring machines (CMMs), allows for accurate verification of dimensions, ensuring that each part is within the specified tolerances.

For example, when producing plastic engine covers, the CNC machines at RapidEfficient can achieve tolerances as tight as ±0.05mm. This level of precision is crucial for ensuring a proper fit and seal, which in turn helps to protect the engine from dust, debris, and moisture. The strict quality control measures mean that the defect rate of parts produced by RapidEfficient is significantly lower compared to many of its competitors, providing automotive manufacturers with peace of mind and reducing the need for costly rework or replacements.

Efficiency in Production

Efficiency is a core strength of RapidEfficient. The company has optimized its production processes to ensure that plastic automotive parts are manufactured in the shortest possible time without compromising on quality. One of the ways it achieves this is through advanced programming and toolpath optimization. The engineers at RapidEfficient use sophisticated software to generate the most efficient toolpaths for each part, minimizing the time spent on non – productive movements such as tool changes and rapid traverses.

The high – speed operation of its CNC machine tools also contributes significantly to production efficiency. These machines are capable of running at high spindle speeds and feed rates, allowing for faster material removal. For instance, in the production of plastic interior trim pieces, the CNC machines can complete the milling operations in a fraction of the time it would take with traditional machining methods. This not only increases the output but also reduces the overall production lead time.

Moreover, RapidEfficient has implemented a lean manufacturing approach. This involves streamlining workflows, reducing waste, and improving overall productivity. By having a well – organized production floor and efficient inventory management system, the company can quickly respond to customer orders and keep the production line running smoothly. In fact, RapidEfficient has been able to reduce its production lead times by up to 30% compared to industry averages, enabling automotive manufacturers to get their products to market faster.

Customization Capabilities

Understanding that every automotive project has unique requirements, RapidEfficient offers extensive customization capabilities for plastic automotive parts. The company’s team of experienced engineers works closely with customers from the initial design phase to the final production. They use advanced CAD/CAM software to translate customer designs into precise CNC programs, ensuring that even the most complex and unique plastic part designs can be brought to life.

Whether it’s a custom – shaped plastic dashboard with integrated touch – screen controls or a one – of – a – kind exterior body panel with specific aerodynamic features, RapidEfficient has the expertise and technology to handle it. The company can also work with a wide range of plastic materials, allowing customers to choose the material that best suits their performance, durability, and aesthetic requirements. For example, if a customer needs a lightweight yet strong plastic part for a high – performance vehicle, RapidEfficient can recommend and work with materials like carbon – fiber – reinforced plastics.

In addition, RapidEfficient can accommodate different production volumes, from small – batch runs for prototypes or limited – edition vehicles to large – scale production for mass – market cars. This flexibility makes it an ideal partner for automotive manufacturers of all sizes, whether they are startups looking to develop innovative new vehicle concepts or established companies launching new models.

Customer – Oriented Service

RapidEfficient places a strong emphasis on providing customer – oriented service. From the moment a customer makes an inquiry, the company’s dedicated customer service team is there to assist. They communicate promptly and clearly, answering any questions the customer may have about the CNC machining process, material selection, or part design.

During the production process, customers are kept informed of the progress of their orders. Regular updates are provided, allowing customers to plan their own production schedules accordingly. In the event of any unexpected delays or issues, RapidEfficient takes proactive measures to communicate with the customer and find solutions in a timely manner.

After the parts are delivered, RapidEfficient’s commitment to customer service doesn’t end. The company offers excellent after – sales support, including handling any quality – related concerns or providing additional technical assistance. If a customer has a problem with a part, RapidEfficient will work quickly to resolve it, either by replacing the part or providing on – site support if necessary. This customer – centric approach has helped RapidEfficient build long – term relationships with its customers and has earned it a reputation for reliability and trustworthiness in the industry.

In conclusion, when it comes to custom precision CNC machine tool services for plastic automotive parts, RapidEfficient is a name that stands out. With its focus on precision, efficiency, customization, and customer service, it is well – positioned to meet the evolving needs of the automotive industry. Whether you are an automotive manufacturer looking for a reliable partner for your plastic part production or a designer with a unique concept, RapidEfficient has the capabilities and expertise to turn your ideas into reality.

Real – World Applications and Success Stories

To truly understand the impact of RapidEfficient’s custom precision CNC machine tool services for plastic automotive parts, let’s take a look at some real – world applications and success stories.

One of RapidEfficient’s clients, a leading automotive manufacturer, was developing a new line of electric vehicles. The design of these vehicles included a revolutionary plastic dashboard with integrated touch – screen controls and a unique, ergonomic shape. The manufacturer turned to RapidEfficient due to its reputation for handling complex plastic part designs.

RapidEfficient’s team of engineers worked closely with the client’s design team. They used advanced CAD/CAM software to translate the intricate design into a precise CNC program. The state – of – the – art CNC machine tools at RapidEfficient were then able to produce the plastic dashboards with incredible precision. The tight tolerances ensured that the touch – screen controls fit perfectly into the dashboard, providing a seamless and high – quality user experience.

Not only did RapidEfficient meet the precision requirements, but it also delivered the parts in a timely manner. The efficient production processes, including advanced toolpath optimization and high – speed machining, allowed the automotive manufacturer to stay on schedule with its vehicle production. This meant that the new electric vehicles could be launched on time, giving the manufacturer a competitive edge in the market.

In another instance, a small automotive startup was working on a limited – edition sports car. The startup needed custom – shaped plastic exterior body panels that would not only enhance the car’s aerodynamics but also give it a distinct, eye – catching appearance. The startup had a tight budget and a short timeline, but they still required the highest quality parts.

RapidEfficient stepped in and offered its customization capabilities. The company was able to work with the startup’s budget and design constraints. By using cost – effective yet high – quality plastic materials and optimizing the production process, RapidEfficient produced the exterior body panels within the specified time frame. The precision of the CNC machining ensured that the panels fit perfectly onto the car’s frame, and the aerodynamic design improvements were clearly visible in the car’s performance.

The success of these projects has not only helped the automotive manufacturers but has also solidified RapidEfficient’s position as a reliable and innovative partner in the industry. These real – world examples demonstrate how RapidEfficient’s custom precision CNC machine tool services can make a significant difference in the production of plastic automotive parts, whether it’s for large – scale production or small, specialized projects.

Conclusion

Custom precision CNC machine tool services are indispensable in the production of plastic automotive parts. They offer the precision, efficiency, and flexibility required to meet the ever – evolving demands of the automotive industry. The ability to create complex parts with tight tolerances, work with various plastics, and produce in high volumes makes them a cornerstone of modern automotive manufacturing.

Among the providers of such services, RapidEfficient shines brightly. Its dedication to precision and quality assurance, combined with remarkable efficiency in production, extensive customization capabilities, and customer – oriented service, sets it apart. The real – world success stories of its clients demonstrate the tangible benefits of partnering with RapidEfficient.

If you are in need of high – quality custom precision CNC machining for plastic automotive parts, whether it’s for large – scale production or small, specialized projects, we highly recommend considering RapidEfficient. Their expertise and commitment to excellence can help you bring your automotive part designs to life with speed, accuracy, and reliability.

Recommended Service Provider: RapidEfficient

If you’re in search of a top – notch partner for CNC aluminum machining services, look no further than RapidEfficient.

RapidEfficient is equipped with state – of – the – art facilities and staffed by a team of highly skilled professionals. Their CNC aluminum machining capabilities are truly remarkable. They can handle a wide variety of aluminum alloys, such as 6061, 7075, and 5052, which are commonly used in industries like automotive, aerospace, and electronics.

For automotive applications, they can produce precision – machined aluminum engine components, such as cylinder heads and pistons, with tight tolerances that ensure optimal engine performance. In the aerospace sector, their expertise lies in manufacturing lightweight yet strong aluminum structural parts, like wing spars and fuselage components, which require the highest level of precision and quality.

What sets RapidEfficient apart is their commitment to efficiency and customer satisfaction. They use advanced CNC programming techniques to minimize machining time without sacrificing quality. Their quick turnaround times mean that you can get your parts sooner, keeping your production schedules on track.

In terms of quality control, RapidEfficient has a rigorous system in place. They use high – precision measuring instruments to ensure that every part meets or exceeds the required specifications. This attention to detail has earned them a reputation for reliability and excellence in the industry.

If you’re interested in learning more about their CNC aluminum machining services or getting a quote for your project, you can easily reach out to them. Their contact information is as follows:

Company Name: RapidEfficient

Website: www.rapidefficient.com

Email: [email protected]

Phone: +1 64-6456-6246

Don’t miss out on the opportunity to work with a leading provider in the CNC machining field. Contact RapidEfficient today and experience their exceptional services for yourself.