In the vast world of manufacturing, injection molding technology has become an important force in product molding and promoting industrial upgrading with its high efficiency, flexibility and low cost. The selection of injection molding materials is one of the key factors that determine product quality, performance and appearance. This article explores the diversity, characteristics and application of materials in manufacturing, and looks forward to how AI technology will bring new opportunities to the selection and optimization of injection molding materials.

one、Diversity of injection molding materials

Injection moldingWide variety of materials,Covers a wide range from thermoplastics to thermosets。in,Thermoplastics such as polyethylene (PE)、Polypropylene (PP)、Polyvinyl chloride (PVC)、ABS、Nylon (PA), etc.,Because it is easy to process、Reusable and recyclable features,Dominant position in molding field。These materials have different physical and chemical properties,such as hardness、toughness、heat resistance、Chemical resistance, etc.,Provides manufacturers with a wealth of choices。

two、Characteristics and applications of injection molding materials

The characteristics of materials directly determine the performance of products. For example, ABS materials are widely used in automobiles, electronics, home appliances and other fields due to their good impact resistance, heat resistance and processing performance; nylon materials are the preferred materials for manufacturing mechanical parts such as gears and bearings due to their high strength, wear resistance and self-lubrication. In addition, with the enhancement of people’s environmental awareness, environmentally friendly materials such as bio-based plastics and degradable plastics are gradually favored by the market, bringing new development opportunities to the injection molding industry.

three、Application of AI technology in injection molding material selection and optimization

With the support of AI technology, material selection and optimization have become smarter and more efficient. Through big data analysis, AI can accurately predict the performance of different materials in different application scenarios and provide manufacturers with scientific material selection recommendations. At the same time, AI can also automatically adjust injection molding process parameters according to product design requirements and production costs to maximize material utilization. In addition, AI technology can also be used in the design and optimization of injection molds to further improve production efficiency and product quality.

Four、Future trends in injection molding materials

In the future, it will develop towards a more environmentally friendly, high-performance and intelligent development. On the one hand, with the enhancement of global environmental awareness, environmentally friendly materials such as bio-based plastics and degradable plastics will become the mainstream trend of the molding industry; on the other hand, in order to meet the market demand for high-performance products, new materials such as high-performance polymers and nanocomposites will continue to emerge. At the same time, the widespread application of AI technology will promote the selection and optimization of materials to a new stage, providing strong support for the sustainable development of the manufacturing industry.

The selection and optimization of molding materials is a key link in the innovative development of the manufacturing industry. With a deep understanding of its diversity and characteristics, combined with the intelligent application of AI technology, manufacturing companies can more accurately select suitable materials and improve product quality and production efficiency.

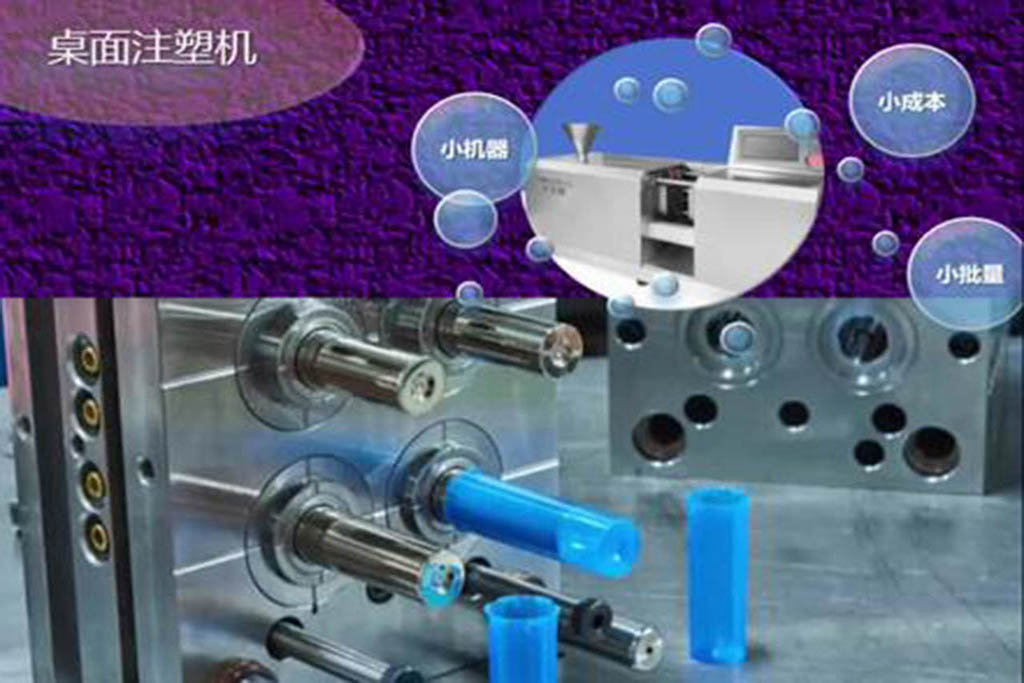

Rapid Efficient is a leading provider of rapid prototyping and parts processing and manufacturing services,Focus on prototype production of plastic and metal parts、Custom processing and small batch production,Provide one-stop service from prototype to mass production。

With advanced manufacturing technology and highly skilled team,We always maintain an excellent competitive advantage。Our manufacturing services meet your specific product design needs,Including CNC machining、3D printing、Silicone mold vacuum injection molding、Rapid molding and small batch injection molding, etc.。

Our business model is based on providing cost-effective solutions,Enable customers to benefit at all stages of their new product development。Our most proud social value is the recognition of customers from all over the world through word-of-mouth growth.,These range from independent inventors or designers to large industrial、Business、medical、car、Medical and other fields