Introduction

In the CNC machining industry, one of the most common technical questions is how to maintain machining accuracy and efficiency when working with high-hardness materials. This issue becomes especially critical when machining materials such as titanium alloys, hardened steel, or high-strength aluminum alloys. These materials present significant machining challenges due to their mechanical properties, and achieving both precision and productivity requires a combination of correct tooling, optimized parameters, and advanced machining strategies.

This guide explains practical, proven techniques used in real production environments to successfully machine high-hardness materials while maintaining dimensional accuracy, surface quality, and tool life.

Understanding the Challenges of High-Hardness Materials

High-hardness materials typically exhibit the following characteristics:

- High cutting resistance

- Rapid tool wear

- Concentrated heat generation

- Increased vibration risk

- Difficult chip evacuation

In general machining practice, materials above HRC 45 are widely considered difficult-to-machine materials. When machining these materials, improper process settings can quickly lead to tool failure, poor surface finish, or dimensional deviation.

Tool Selection: The Foundation of Successful Machining

Selecting the correct cutting tool is the first and most important step.

Recommended tool types

- Tungsten carbide tools

- Coated carbide tools

- Ceramic tools (for hardened steels)

- CBN tools (for ultra-hard materials)

Recommended coatings

- TiN — general wear resistance

- TiAlN — excellent high-temperature stability

- AlTiN — superior for high-speed cutting

- DLC — ideal for non-ferrous materials

Proper tool geometry is equally important. Optimized rake angle, clearance angle, and edge preparation can distribute cutting force more evenly, reducing localized stress and extending tool life.

Cutting Parameter Optimization

Precision control of machining parameters is essential when working with high-hardness materials.

| Parameter | Recommended Strategy |

|---|---|

| Cutting Speed | Lower speeds reduce heat buildup |

| Feed Rate | Moderate feed improves stability |

| Depth of Cut | Shallow passes reduce tool load |

| Step-over | Smaller engagement improves control |

Professional manufacturers often conduct test cuts to determine the optimal parameter combination for each material and geometry.

Cooling and Lubrication Strategies

Cooling plays a decisive role in machining hard materials. Proper coolant application can:

- Reduce tool temperature

- Prevent thermal deformation

- Improve chip evacuation

- Enhance surface finish

Recommended cooling methods:

- High-pressure coolant systems

- Oil-based coolant for difficult materials

- Through-tool coolant delivery

- Minimum Quantity Lubrication (MQL) for certain alloys

Inadequate cooling is one of the most common causes of premature tool failure.

Efficient Toolpath Planning

Toolpath strategy has a major impact on machining stability and productivity.

Effective approaches include:

- Progressive step-down cutting

- Adaptive clearing strategies

- Constant engagement toolpaths

- Trochoidal milling for hard materials

These strategies reduce cutting force spikes, minimize tool stress, and maintain stable machining conditions throughout the process.

Achieving Superior Surface Quality

For high-precision components, surface finish is just as important as dimensional accuracy.

Methods to improve surface quality:

- Use dedicated finishing tools

- Reduce feed rate during finishing passes

- Balance cutting forces

- Apply secondary finishing passes

- Ensure rigid fixturing

Proper finishing strategy not only improves appearance but also enhances fatigue resistance and functional performance.

Benefits of Working with an Experienced CNC Machining Partner

Machining high-hardness materials requires technical expertise, advanced equipment, and process optimization experience. A professional machining partner can:

- Select optimal tools for each material

- Determine precise cutting parameters

- Design efficient machining strategies

- Reduce machining time and cost

- Improve overall part consistency

Engineering support during project planning often results in significant cost savings and performance improvements.

About RapidEfficient

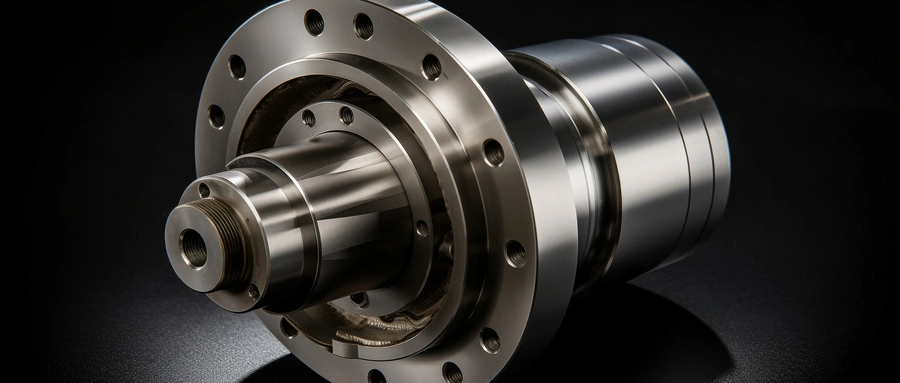

RapidEfficient specializes in high-precision CNC machining with 18 years of experience.

Its products serve industries including medical, communications, optics, drones, intelligent robotics, automotive, and office automation parts.

The company’s CNC machining centers feature four-axis, five-axis, and multi-linkage machine tools, and are equipped with precision projectors, coordinate measuring machines (CMM), spectrometers, and other advanced inspection equipment.

Machining accuracy can reach 0.01 mm, and testing accuracy can reach 0.001 mm.

With these capabilities, complex high-hardness materials can be machined with consistent precision, ensuring reliable quality for demanding engineering applications.

Conclusion

Handling high-hardness materials in CNC machining is a technical challenge that requires knowledge, experience, and the right process control methods. When these elements are applied correctly, manufacturers can successfully produce high-precision components while maintaining tool life and production efficiency. Mastering these techniques allows CNC machining providers to meet strict tolerance requirements and deliver reliable, high-performance parts for demanding industries.