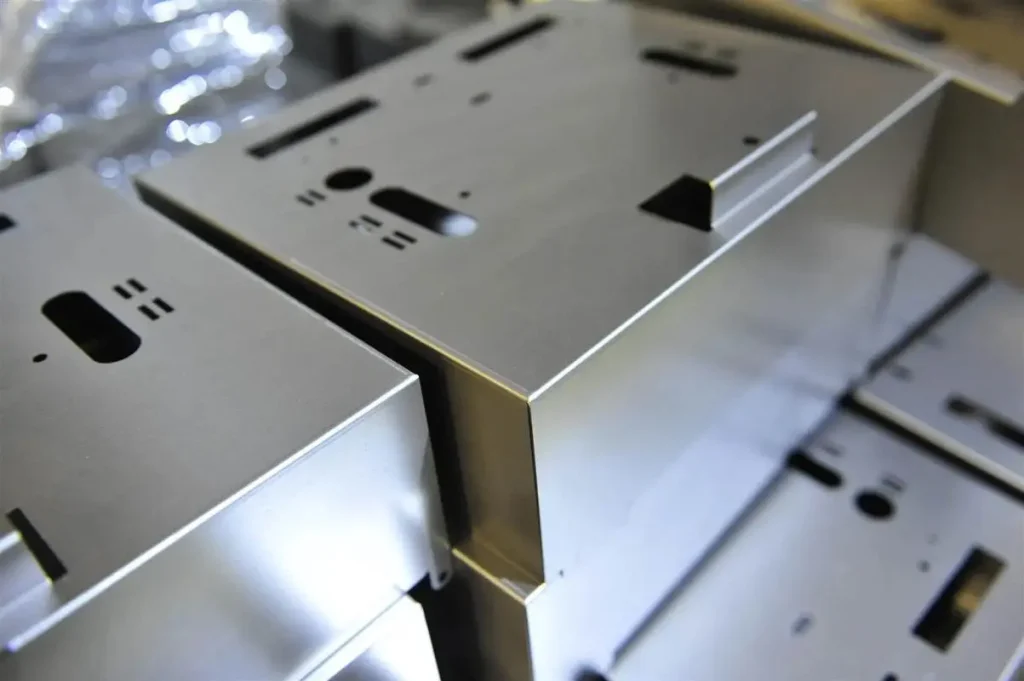

In modern industry, precision gears and precision sheet metal parts are the critical backbone supporting the operation of high-end equipment. Micron-level dimensional tolerances and perfect contour alignment directly determine product performance and lifespan. Ensuring this precision is a systematic effort throughout the entire process.

A Precision Foundation in Design:

Precision begins with the rigor of the digital world. Advanced CAD/CAM software not only enables complex structural design but also enables precise simulation, predicting stress and deformation trends in materials during stamping and bending, and preventing design flaws at the source. Material selection is equally critical, requiring a precise match between physical properties and processing requirements—strength, ductility, and thermal expansion coefficient all need to be considered to ensure the material is inherently capable of supporting precision forming.

Equipment and Environment: The Physical Pillars of Precision:

Precision processing relies on the stable performance of cutting-edge equipment. High-precision laser cutting machines, servo CNC punching machines, and multi-axis bending centers are powerful tools in modern sheet metal processing, requiring micron-level repeatability. However, even the most sophisticated equipment requires meticulous care: regular maintenance and precision calibration must be strictly implemented, and a system for monitoring equipment status must be established. Furthermore, the processing environment cannot be neglected. A constant temperature and humidity workshop can eliminate the effects of thermal expansion and contraction, and effective foundation vibration damping measures isolate external interference, creating a stable and stable environment for precision machining.

The Fine Art of Process Control:

Process parameters are the invisible hand of precision. Power, speed, and assist air pressure in laser cutting; die selection, pressure level, and compensation angle in bending—each parameter must be scientifically set and dynamically fine-tuned based on material properties and thickness. Experienced operators can “read” the equipment’s status from subtle noises and spark patterns. Combined with an automated real-time monitoring system, this ensures the machining process is always on track. Precision clamping and specialized mold design provide the physical guarantee for maintaining the workpiece’s immovability under strong external forces and achieving precise forming.

Mold and tool management and human-machine collaboration:

“To do one’s work well, one must first sharpen their tools.” The wear of molds and tools directly affects machining accuracy and edge quality. A strict lifespan tracking and regular inspection system must be established to promptly replace or repair worn parts. Operator skills and quality awareness are the last line of defense. Continuous professional training ensures not only proficiency in equipment operation but also the ability to keenly identify potential problems and strictly adhere to standardized operating procedures.

Quality Inspection: The Cornerstone of Closed-Loop Control:

Precision is ultimately determined by data. High-precision coordinate measuring machines (CMMs) and laser scanners enable comprehensive inspection of finished products to micron-level dimensions, form, and position tolerances. A rigorous inspection system—mandatory first-article inspection, in-process spot checks, and final-article review—is essential. Even more crucial is the establishment of a real-time feedback mechanism for inspection data to quickly identify anomalies, trace back process steps, and drive parameter adjustments and process optimization, forming a closed loop of continuous improvement.

Ensuring the precision of precision sheet metal processing is not the work of a single step; it is a systematic project that integrates the multi-dimensional collaboration of design, equipment, processes, personnel, and inspection. Only by implementing the pursuit of “zero tolerance” precision at every node, supplemented by scientific management and technological empowerment, can we build a solid backbone of industrial manufacturing within millimeters and drive products to continue climbing to the peak of performance and reliability.