Common stainless steel precision parts are typically manufactured using standard grades such as 303, 304, 316, and 420. Stainless steel parts are ubiquitous in both heavy and light industry, as well as in our daily lives, due to their excellent formability, compatibility, corrosion resistance, and strong rigidity.

Typically, alloys with a chromium content greater than 12% or a nickel content greater than 8% are referred to as stainless steel. These materials offer excellent corrosion resistance in atmospheric and corrosive environments and maintain exceptional rigidity at extremely high temperatures (typically >450°C). Steels with a chromium content of 16% to 18% are called acid-resistant steel or acid-resistant stainless steel. However, since we don’t specialize in steel refining, we generally refer to them all as stainless steel.

However, as a precision stainless steel parts manufacturer, we must understand stainless steel grades, their corresponding properties, and the applications they serve. For example, applications in aerospace, petrochemicals, construction, transportation, and household kitchenware all have different material requirements.

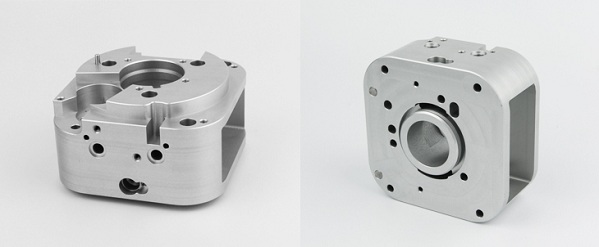

Many manufacturers are confused when it comes to precision machining stainless steel. Different grades of stainless steel have varying hardness and slightly different properties. Are there any challenges in CNC machining stainless steel? RapidEfficient, with 18 years of experience specializing in precision stainless steel parts machining, has compiled a list of the challenges of stainless steel machining. Let’s take a look at what they are.

1. High Cutting Forces

Stainless steel undergoes significant plastic deformation during cutting, increasing cutting forces. Stainless steel’s severe work hardening and high thermal strength further increase cutting resistance, making chip curling and breaking more difficult.

2. Severe Work Hardening

Stainless steel has high plasticity, resulting in distorted grains during plastic deformation and a high strengthening coefficient. Furthermore, the austenite is unstable, and under the influence of cutting stress, some austenite transforms into martensite. Furthermore, compound impurities are easily decomposed and dispersed by the cutting heat, resulting in a hardened layer during cutting. Work hardening from a previous feed or process can severely impact the smooth progress of subsequent processes.

3. Chips are difficult to break and easily stick together

Stainless steel has high plasticity and toughness. During CNC machining, continuous chips form, not only hindering smooth operation but also damaging the machined surface. Under high temperature and pressure, stainless steel has a strong affinity with other metals, easily causing adhesion and built-up edge formation. This not only increases tool wear but also causes tearing, deteriorating the machined surface.

4. High cutting temperature

During cutting, plastic deformation and friction with the tool are both significant, generating significant cutting heat. A large amount of cutting heat is concentrated in the cutting zone and the tool-chip interface, resulting in poor heat dissipation.

5. High linear expansion coefficient

The linear expansion coefficient of stainless steel is approximately 1.5 times that of carbon steel. Under the influence of cutting temperatures, workpieces are prone to thermal deformation, making dimensional accuracy difficult to control.

6. Tool Wear

The affinity effect during stainless steel cutting causes adhesion and diffusion between the tool and the chip, resulting in adhesive and diffusion wear on the tool. This leads to craters on the tool rake face and tiny flaking and chipping on the cutting edge. Furthermore, the carbide particles (such as TiC) in stainless steel are very hard, which directly contact and rub against the tool during cutting, causing scratches and work hardening, all of which exacerbate tool wear.

Through the above analysis, we know that the difficulties in cutting stainless steel precision parts primarily manifest in cutting force, work hardening, high viscosity, high temperature, large linear expansion coefficient, and easy tool wear.

Understanding these characteristics of stainless steel machining allows us to select the right machine tool, tool, tool path, cutting parameters, cutting fluid, and other measures to ensure product quality.

RapidEfficient specializes in high-precision CNC machining with 18 years of experience. Its products cover medical, communications, optics, drones, intelligent robots, automotive and office automation parts. The company’s CNC machining centers include four-axis, five-axis and linkage machine tools, and are equipped with precision projectors, three-coordinate measuring machines, spectrometers and other precision testing equipment. The machining accuracy can achieve 0.01mm and the testing accuracy can achieve 0.001mm.