In the realm of manufacturing, precision is paramount. When it comes to Computer Numerical Control (CNC) machining, the pursuit of accuracy and efficiency knows no bounds. With the rise of Rapidefficient as a precision CNC machining supplier, questions about the cost-effectiveness of their services have naturally arisen. This article delves into the intricacies of CNC machining, the market landscape, technological advancements, and the unique value proposition that Rapidefficient brings to the table. By the end, you’ll have a clearer understanding of whether their pricing aligns with the exceptional quality and efficiency they promise.

CNC Machining: The Basics

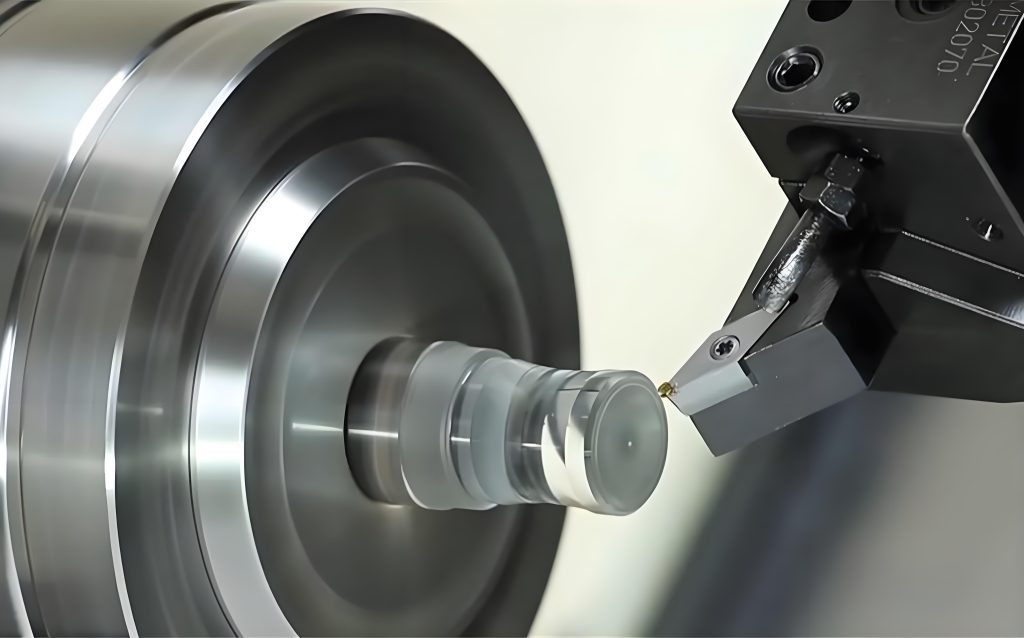

CNC machining is a subtractive manufacturing process that involves the use of computer-controlled tools to cut away material from a workpiece, creating intricate and precise parts. This technology has revolutionized the manufacturing industry, enabling the production of components with unparalleled accuracy and repeatability. From automotive parts to aerospace components, medical devices to electronic gadgets, CNC machining plays a vital role in shaping our modern world.

The process begins with a CAD (Computer-Aided Design) drawing of the desired part. This digital design is then converted into a series of machine-readable instructions, known as G-code, which guides the CNC machine tools. These tools can include milling machines, lathes, drills, and grinders, each tailored to specific tasks. The CNC machine, equipped with multi-axis capabilities, follows the G-code instructions to precisely remove material from the workpiece, resulting in a finished part that matches the original design with remarkable precision.

Market Landscape: Competitive yet Evolving

The CNC machining market is highly competitive, with numerous suppliers offering a range of services and pricing models. This competition drives innovation, pushing suppliers to adopt new technologies and improve their processes to stay ahead. However, with competition, there’s also a tendency for some providers to cut corners, compromising on quality to offer lower prices.

On the other hand, the market is evolving rapidly. Advancements in machine tool technology, software, and materials are continually pushing the boundaries of what’s possible. This evolution brings new opportunities for suppliers like Rapidefficient to differentiate themselves through superior precision, efficiency, and quality.

Technological Innovations Shaping CNC Machining

One of the most significant trends in CNC machining is the adoption of advanced materials. Traditional materials like metals and plastics are still widely used, but newer materials such as ceramics, composites, and even 3D-printed metals are gaining traction. These materials offer unique properties that can enhance the performance of machined parts, but they also require specialized machining techniques and equipment.

Another critical innovation is the integration of artificial intelligence (AI) and machine learning (ML) into CNC machining processes. AI-powered predictive maintenance can anticipate and prevent machine failures, reducing downtime and maintenance costs. ML algorithms can optimize machining parameters in real-time, improving accuracy and efficiency. These technologies are not yet ubiquitous, but their potential to transform the industry is immense.

Rapidefficient: A Precision CNC Machining Supplier

Rapidefficient stands out in the crowded CNC machining market by focusing on precision, efficiency, and quality. Their commitment to excellence is evident in every aspect of their operations, from the advanced machinery they use to the skilled technicians who operate them.

Rapidefficient’s CNC machines are equipped with the latest technology, including multi-axis capabilities and high-speed spindles. This enables them to produce parts with remarkable accuracy and repeatability, even in complex geometries. Their machines are also designed for maximum efficiency, reducing cycle times and production costs without compromising quality.

In addition to state-of-the-art equipment, Rapidefficient invests heavily in training and development for their technicians. This ensures that they have the knowledge and skills necessary to operate the machines effectively and troubleshoot any issues that arise. This focus on human capital is crucial, as the expertise of the technicians often determines the success of a machining project.

Quality control is another area where Rapidefficient excels. They employ rigorous inspection processes, including in-process and final inspections, to ensure that every part meets the customer’s specifications. They also offer comprehensive documentation and traceability, providing customers with peace of mind regarding the quality and origin of their parts.

Cost Considerations: Is Rapidefficient Expensive?

The question of whether Rapidefficient’s pricing is expensive depends on several factors. Firstly, it’s essential to consider the value that Rapidefficient brings to the table. With their precision, efficiency, and quality, they offer a level of service that many other suppliers cannot match. This value is reflected in their pricing, but it’s crucial to weigh it against the potential cost savings and quality improvements that Rapidefficient can deliver.

Secondly, the cost of CNC machining can vary significantly based on the complexity of the part, the material used, and the quantity produced. Simple parts made from common materials in large quantities can be machined more cost-effectively than complex parts made from exotic materials in small batches. Rapidefficient’s pricing is tailored to each project, taking into account these variables and the specific needs of the customer.

Finally, it’s worth considering the long-term benefits of working with Rapidefficient. Their commitment to precision and quality can reduce the need for rework and scrap, lowering overall production costs. Their efficiency can shorten lead times, enabling customers to get their parts faster and meet tight deadlines. These benefits can outweigh the initial cost of working with Rapidefficient, making them a valuable partner in the long run.

Conclusion: The True Cost of Precision and Efficiency

In conclusion, the price of Rapidefficient’s precision CNC machining services is not simply a matter of cost. It’s a reflection of the value they bring to their customers through precision, efficiency, and quality. While their pricing may be higher than some competitors, the benefits they offer in terms of accuracy, reliability, and cost savings can make them a wise investment for many manufacturing projects.

When considering the cost of Rapidefficient’s services, it’s essential to look beyond the initial price tag and consider the overall value they provide. Their advanced machinery, skilled technicians, and rigorous quality control processes ensure that customers receive parts that meet their specifications and perform reliably in their applications. This level of service can be invaluable in competitive markets where precision and efficiency are critical success factors.

Rapidefficient: Your Trusted Partner in CNC Aluminum Machining

If you’re looking for a precision CNC machining supplier that offers exceptional value, look no further than Rapidefficient. With their focus on precision, efficiency, and quality, they are the perfect partner for your next manufacturing project. Whether you need custom aluminum parts for your automotive application or precision components for your aerospace system, Rapidefficient has the expertise and capabilities to deliver.

Visit Rapidefficient’s website today to learn more about their services and see how they can help you achieve your manufacturing goals. Don’t let the perception of high pricing deter you from experiencing the true value of precision CNC machining with Rapidefficient.