Introduction

Mechanical machining is a cornerstone of modern prototype development, bridging the gap between design concepts and tangible products. From precision cutting to detailed shaping, mechanical machining ensures that prototypes meet stringent requirements for functionality, aesthetics, and manufacturability. This article delves into the vital role of mechanical machining in prototype development and highlights why Rapidefficient stands out as a trusted CNC machining service provider.

What is Mechanical Machining in Prototype Development?

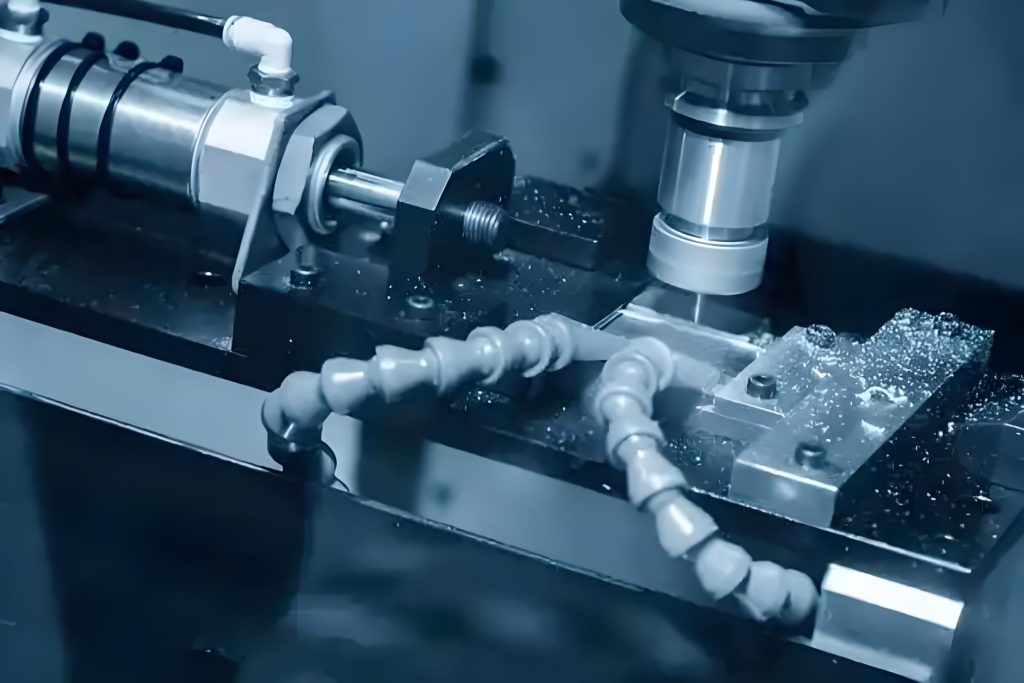

Mechanical machining involves the use of tools and machines like CNC (Computer Numerical Control) equipment to shape raw materials into parts or prototypes. This process is highly precise, making it essential for industries ranging from aerospace to consumer electronics.

Key aspects include:

- Precision Engineering: Delivering exact dimensions and tolerances.

- Versatility in Materials: Compatible with metals, plastics, and composites.

- Scalability: Suitable for one-off prototypes or low-volume production.

The Importance of Mechanical Machining in Prototyping

1. Accuracy and Reliability

Prototypes must replicate the final product as closely as possible. Mechanical machining ensures:

- Tight dimensional tolerances.

- Consistent results across iterations.

2. Fast Turnaround Time

Using advanced CNC machining, processes are automated and optimized, reducing lead times significantly. Companies like Rapidefficient specialize in delivering high-quality prototypes in short timeframes, helping clients stay ahead in competitive markets.

3. Cost-Effective Development

By minimizing errors and material waste, mechanical machining offers a cost-efficient solution for prototype creation. This is especially critical during early design stages when adjustments are frequent.

Advantages of Using CNC for Prototype Machining

- Automated Precision: CNC machines eliminate human error, ensuring perfect replication of designs.

- Flexibility in Design Adjustments: Rapid reprogramming makes it easy to adapt prototypes.

- Wide Range of Applications: CNC machining supports industries like automotive, medical devices, and robotics.

Example: A prototype medical device requires tight tolerances for safety and functionality. CNC machining ensures flawless execution, critical for regulatory approval.

Why Choose Rapidefficient for Mechanical Machining?

Expertise and Advanced Technology

Rapidefficient utilizes state-of-the-art CNC machines capable of handling complex designs with unparalleled precision. Their team of skilled engineers ensures every prototype meets client expectations.

Customization and Scalability

Whether you need a single prototype or a batch of components, Rapidefficient tailors its services to meet diverse project requirements.

Commitment to Quality and Speed

Rapidefficient prioritizes quality without compromising delivery speed. This dual focus positions them as a trusted partner for businesses aiming to fast-track product development.

Sustainability Practices

By leveraging efficient machining processes, Rapidefficient minimizes material waste, aligning with eco-friendly practices and reducing production costs.

Tips for Optimizing Prototype Development

Invest in Detailed CAD Models

High-quality CAD designs are the foundation of successful machining. Ensure your designs are detailed and error-free before machining begins.

Choose the Right Material

Select materials that balance strength, durability, and cost-efficiency. Rapidefficient offers guidance to help you make the best choice for your project.

Partner with Experts

Collaborating with experienced machining providers like Rapidefficient saves time and ensures top-notch results.

Conclusion

Mechanical machining is the backbone of prototype development, offering precision, speed, and cost-effectiveness. Whether you’re an entrepreneur developing a new product or a corporation refining a design, CNC machining is indispensable.

When it comes to reliable, high-quality machining services, Rapidefficient stands out as a market leader. Their commitment to excellence, speed, and sustainability ensures your prototypes are in the best hands.

Contact Rapidefficient today to turn your ideas into reality.