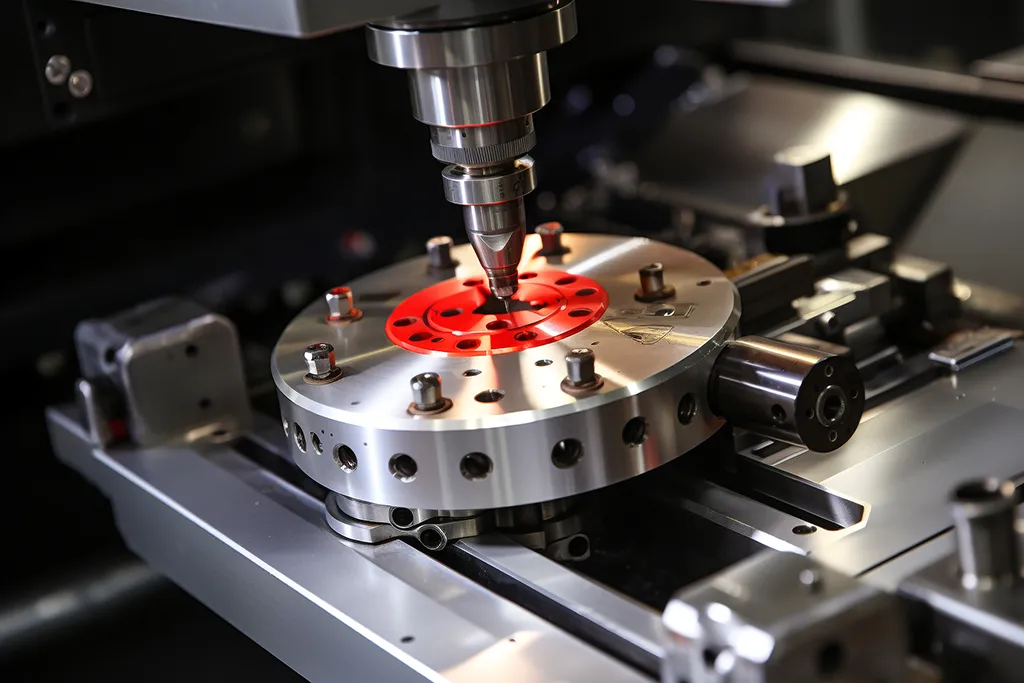

CNC aluminum machining produces various parts used in many industries. Understanding these common parts can help businesses make informed decisions. This article explores the most frequently manufactured CNC aluminum components and their applications.

1. Brackets

Brackets are essential components in numerous applications. They provide support and stability for various structures. CNC machining creates brackets with precise dimensions. This accuracy ensures they fit perfectly in assemblies. Companies often use aluminum brackets in automotive and aerospace industries due to their lightweight and durable nature.

2. Housings

Aluminum housings protect sensitive equipment. They shield electronics from dust, moisture, and damage. CNC machining allows manufacturers to create custom housings tailored to specific needs. This customization enhances functionality and aesthetics. Industries like telecommunications and consumer electronics heavily rely on these parts.

3. Heat Sinks

Heat sinks are crucial in managing heat in electronic devices. They dissipate heat away from critical components. CNC machining produces heat sinks with intricate designs for optimal airflow. These parts are vital in computers, LED lights, and power electronics. Effective heat management extends the lifespan of devices, making quality heat sinks essential.

4. Enclosures

CNC aluminum enclosures provide a protective shell for electronic devices. They prevent damage and interference from external elements. Manufacturers can create enclosures in various shapes and sizes. This flexibility allows for a wide range of applications. Industries such as robotics and automation often utilize these enclosures.

5. Plates

Aluminum plates serve multiple purposes in various industries. They can be used as mounting surfaces, supports, or components in larger assemblies. CNC machining produces plates with specific thicknesses and dimensions. This precision ensures compatibility with other parts. Companies in construction and manufacturing frequently use aluminum plates.

6. Connectors

Connectors are vital for establishing electrical connections. CNC machining produces connectors that are reliable and durable. These parts often feature complex geometries for secure fitment. Industries like automotive and telecommunications require high-quality connectors for efficient operations.

7. Custom Parts

One of the ultimate advantages of CNC machining is the ability to create custom parts. Businesses can design components that meet their specific requirements. Whether for prototypes or production runs, CNC machining offers flexibility. This customization allows companies to innovate and improve their products.

Benefits of CNC Aluminum Parts

CNC aluminum parts offer several benefits. First, they are lightweight yet strong, making them ideal for various applications. Second, aluminum is corrosion-resistant, which enhances the longevity of parts. Third, CNC machining ensures high precision and consistency in production. These benefits make CNC aluminum components popular among manufacturers.

Choosing the Right Supplier

Selecting the right CNC machining supplier is crucial. Look for a company with a solid reputation and experience in producing aluminum parts. They should have advanced CNC equipment and a skilled workforce. Communication is essential as well. A reliable supplier will discuss your needs and provide expert advice.

Additionally, consider their quality control processes. A good supplier will implement rigorous testing and inspection methods. This ensures that the final products meet the required standards. Checking customer reviews can also provide insight into their reliability.

Conclusion

In conclusion, CNC aluminum machining produces a wide range of common parts. Brackets, housings, heat sinks, enclosures, plates, connectors, and custom parts all play significant roles in various industries. Understanding these components helps businesses choose the right solutions for their needs. By selecting a reputable CNC machining supplier, companies can ensure high-quality parts that enhance their products. Whether for prototyping or mass production, CNC aluminum parts deliver precision and durability.